Polybasic carboxylic acid non-ironing process washing-free method adopting urea as additive

A polycarboxylic acid and additive technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of low pH value of fabrics, and achieve the effects of improved wrinkle recovery angle, improved fabric strength, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

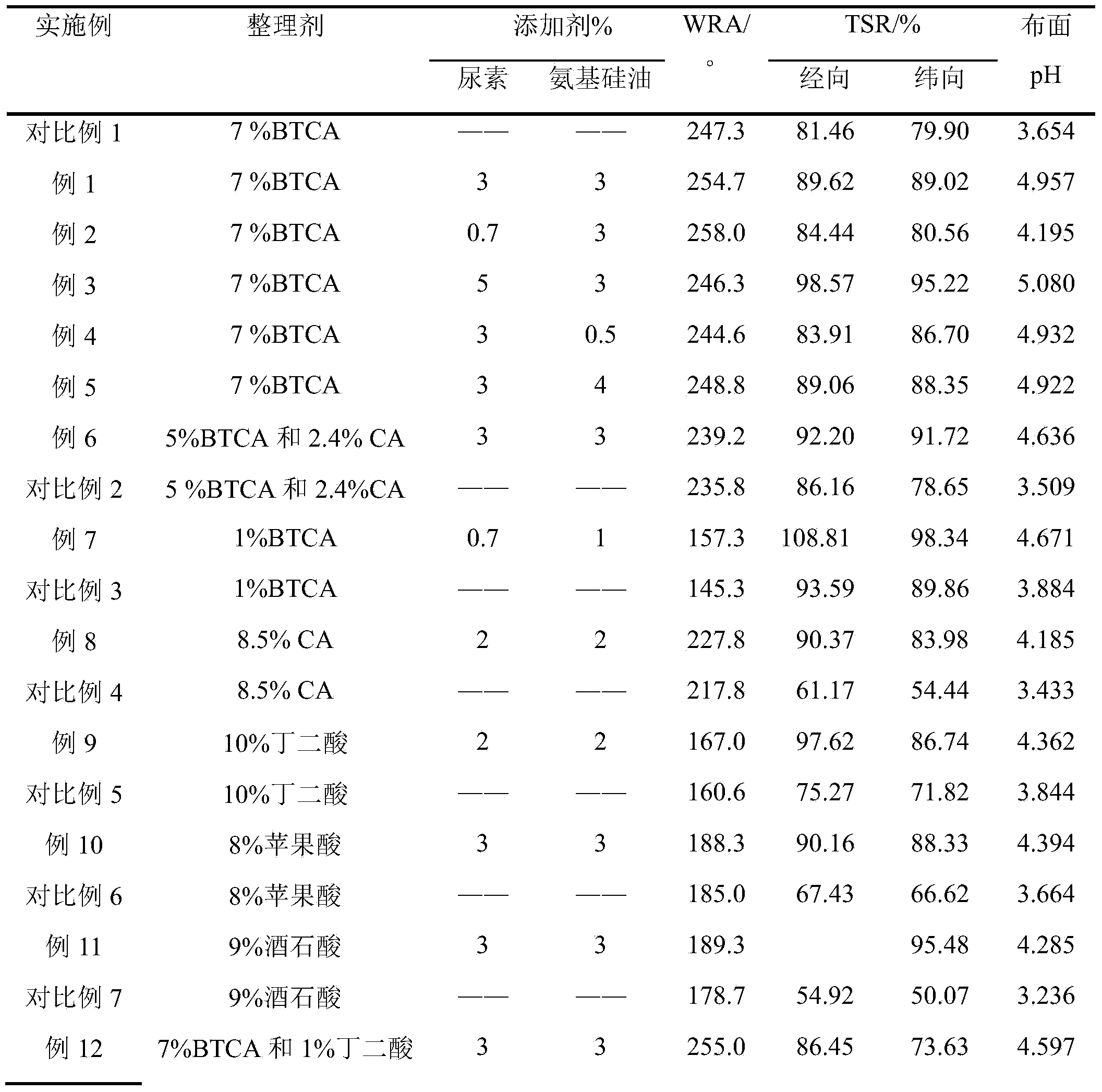

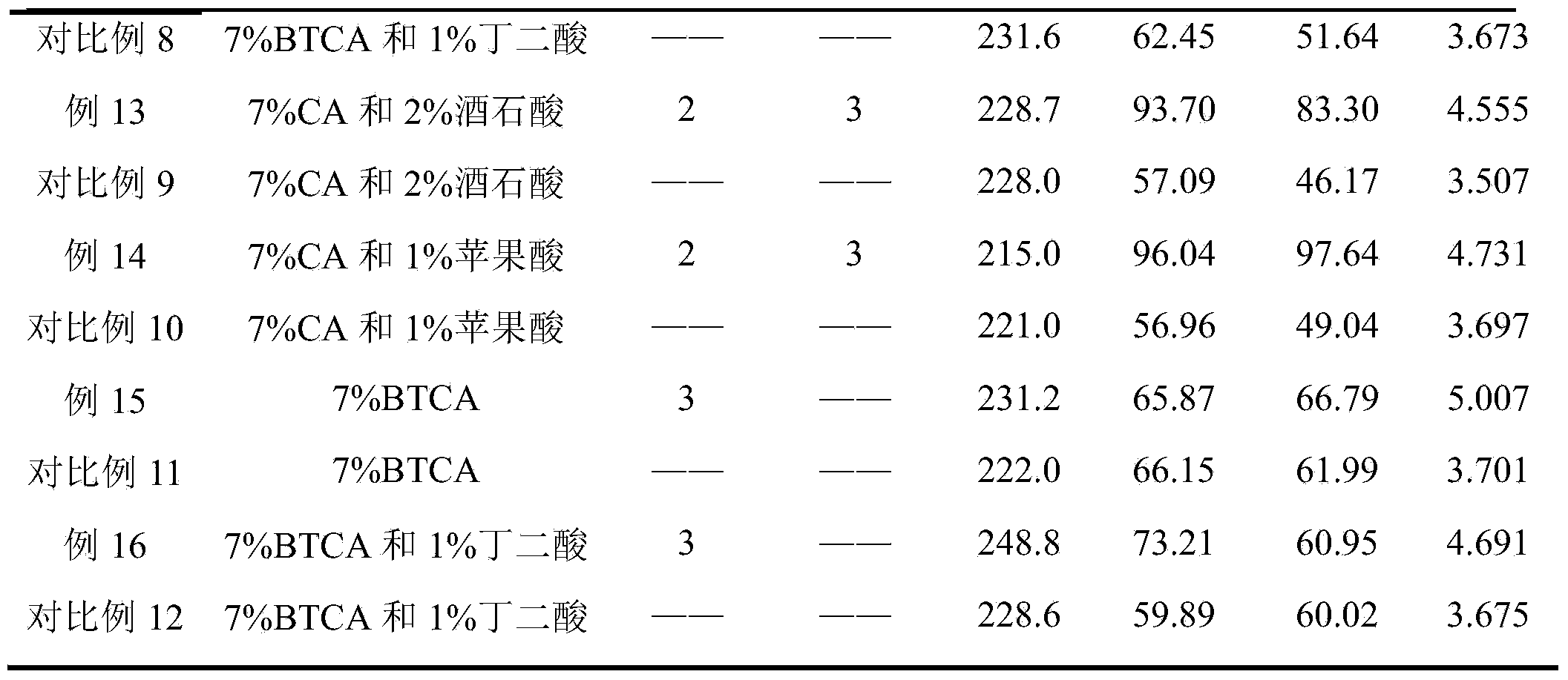

[0020] Prepare finishing solution, add 7% formaldehyde-free finishing agent BTCA, 1.6% catalyst SHP, 3% urea and 3% amino silicone oil, 3% strong protective agent HD-208, 0.5% penetrating agent HD-2 into the finishing solution. The fabric was dipped twice and rolled twice, the excess rate was 90%, dried at 100°C for 2 minutes, baked at 160°C for 3 minutes, and the pH of the tested cloth surface was 4.957. The crease recovery angle and tear strength retention rate of the fabric are shown in Table 1.

Embodiment 2

[0024] Prepare finishing solution, add 7% formaldehyde-free finishing agent BTCA, 1.6% catalyst SHP, 0.7% urea and 3% amino silicone oil, 3% strong protective agent HD-208, 0.5% penetrating agent HD-2 into the finishing solution. The fabric was dipped twice and rolled twice, the excess rate was 90%, dried at 100°C for 2 minutes, baked at 160°C for 3 minutes, and the pH of the tested cloth surface was 4.195. The crease recovery angle and tear strength retention rate of the fabric are shown in Table 1.

Embodiment 3

[0026] Prepare finishing solution, add 7% formaldehyde-free finishing agent BTCA, 1.6% catalyst SHP, 5% urea and 3% amino silicone oil, 3% strong protective agent HD-208, 0.5% penetrating agent HD-2 into the finishing solution. The fabric was dipped twice and rolled twice, the excess rate was 90%, dried at 100°C for 2 minutes, baked at 160°C for 3 minutes, and the pH of the tested cloth surface was 5.080. The crease recovery angle and tear strength retention rate of the fabric are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com