Device and method for producing top and bottom electrode type conducting concrete slabs for indoor heating

A conductive concrete slab and electrode technology, applied in the field of conductive concrete, can solve the problems of inability to precisely control the position between two electrodes of the conductive concrete, uneven heating of the conductive concrete slab, complicated construction techniques, etc., and achieve economical production. , The effect of stable and uniform heating and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation device and preparation method of the present invention will be further described below by taking the conductive concrete slab of 600 × 600 × 12mm as an example. The following examples are only used to illustrate the technical solutions of the present invention, rather than to the scope of protection of the present invention. Although the present invention has been described in detail with reference to preferred embodiments, those skilled in the art should understand that the technical solutions of the present invention can be modified or equivalently replaced without departing from the essence and nature of the technical solutions of the present invention. scope.

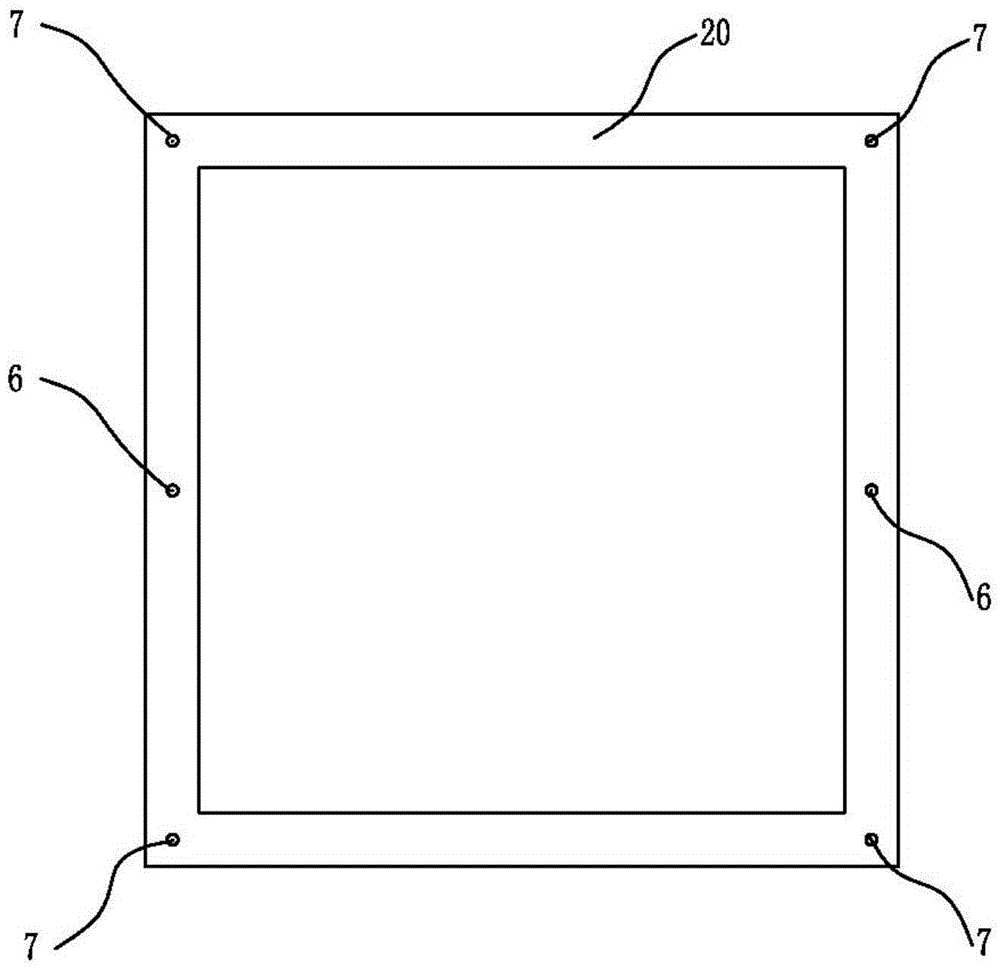

[0049] The invention creates a device for preparing upper and lower electrode type conductive concrete slabs for indoor heating, which includes a tensioning device 3, a bottom template 1 and a frame-shaped forming side mold 2.

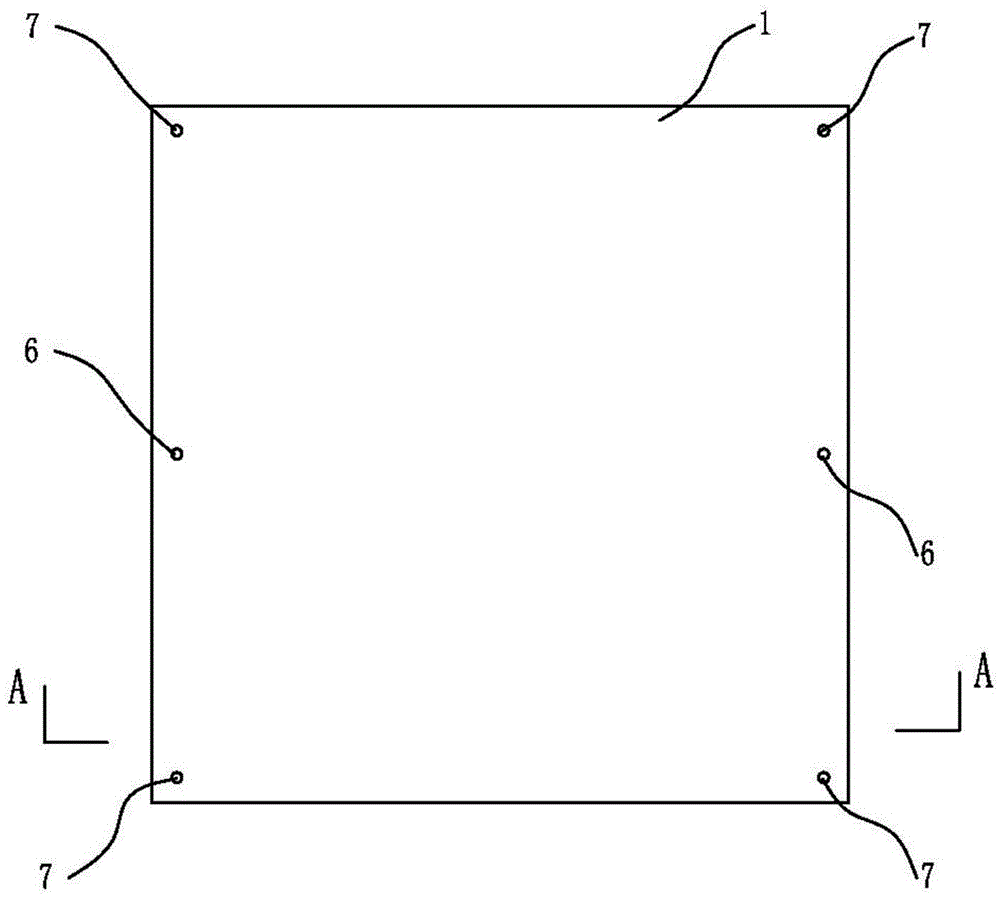

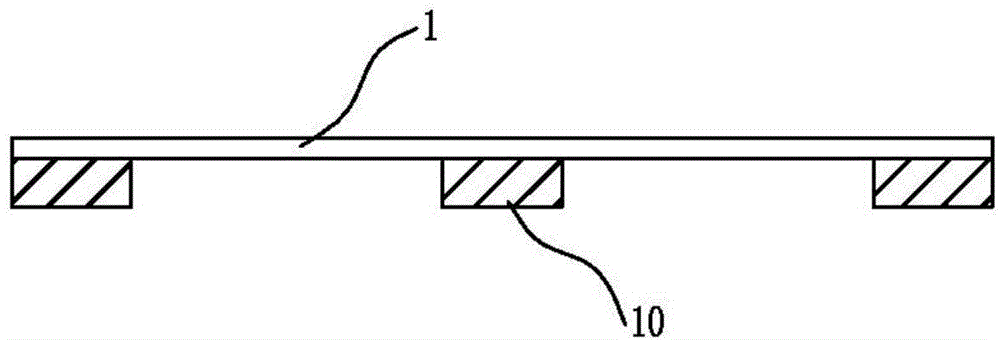

[0050] Bottom template 1, such as figure 1 with figure 2 As sh...

Embodiment 2

[0063] The main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the two pressure clamps 31 can be vertically lifted and adjusted in height, and the vertical lift of the pressure clamps 31 makes the pressure clamps 31 and the internal pressure clamps 31 by shaking the adjustment hand wheel (not shown). The screw rod (not shown) generates relative rotation to realize the lifting adjustment, and the stepless lifting adjustment of the screw rod is adopted, which is accurate and stable.

[0064]Since the heights of the two pressure clamps 31 are adjustable, in the preparation method of the upper and lower electrode type conductive concrete slabs for indoor heating used in Example 1, before step C, the height of the two pressure clamps 31 can be adjusted to further Adjust the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com