Concave-convex steel bar joint

A technology of steel bars and joint sleeves, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of uneven fixing of concave and convex steel bars, and achieve the effect of simple structure, easy manufacture, and strong bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

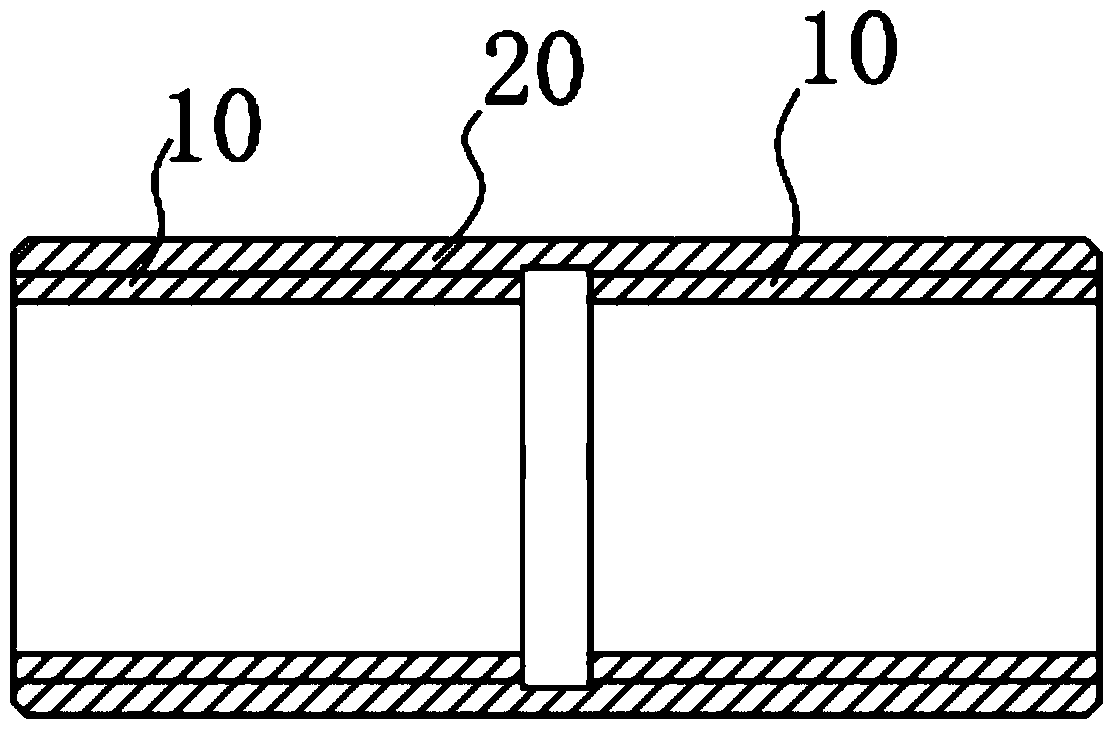

[0028] Such as figure 1 , image 3 , Figure 5 As shown, a concave-convex steel bar joint includes a tubular joint assembly 10 that can be sleeved on the concave-convex steel bar 100. The joint assembly 10 is a detachable structure. When the joint assembly 10 is sleeved on the concave-convex steel bar 100 , the inner wall of the joint assembly 10 fits closely with the concave and convex places on the concave-convex steel bar 100, and also includes a tubular fastener 20 fixedly connected with the joint assembly 10, and the two ends of the fastener 20 are respectively A joint assembly 10 is detachably connected. The outer wall of the joint assembly 10 has an external thread, and the fastener 20 may be in the shape of a sleeve with an internal thread, that is, the inner wall of the fastener 20 has an internal thread that is compatible with the external thread on the external wall of the joint assembly 10, and the joint assembly 10 and The fastener 20 is screwed and fixed. Tha...

Embodiment 2

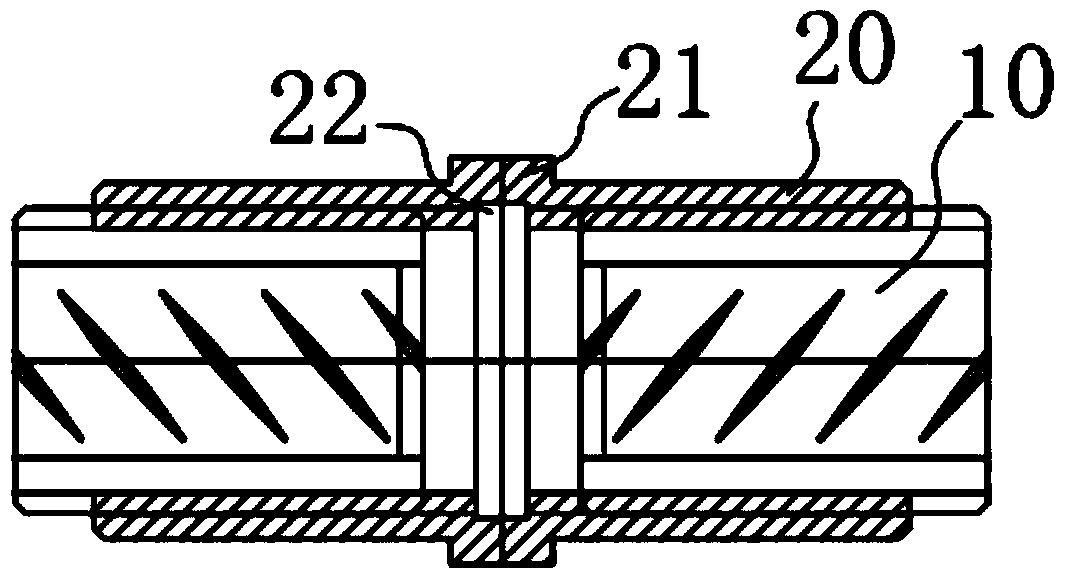

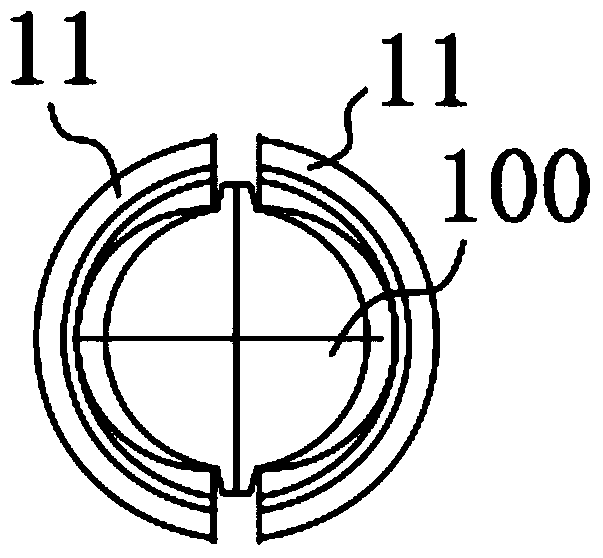

[0036] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 2 , Figure 4 As shown, the joint assembly 10 includes two joint sleeves 11, and the two joint sleeves 11 are rotationally connected through the lock shaft assembly 101, that is to say, the two joint sleeves 11 are connected together through the lock shaft assembly 101, and can be opened or closed. .

[0037] Several reinforcing ribs 21 are provided on the outer wall of the fastener 20 , and the reinforcing ribs 21 are in the shape of a ring, which can strengthen the fastener 20 radially and improve the radial tensile strength of the fastener 20 . At least one reinforcing rib 21 is arranged in the middle of the fastener 20, and an annular expansion hole 22 is provided on the inner wall of the fastener 20 corresponding to the position of the reinforcing rib 21, when the concave-convex reinforcing bar 100 When the joint assembly 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com