Novel tensioner

A tensioner, a new type of technology, applied in the field of auto parts, can solve the problems of increased vibration of the wheel train system, unguaranteed quality, cumbersome production process, etc., to achieve a long service life, reliable quality, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

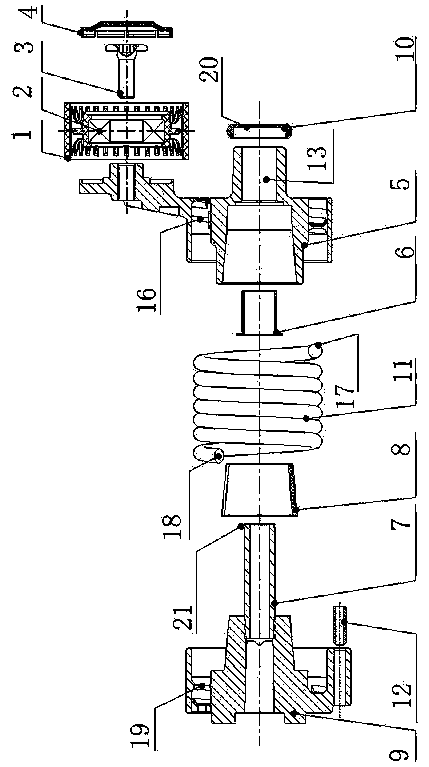

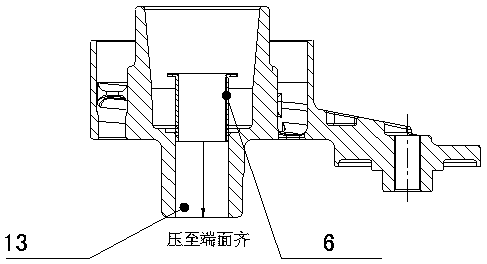

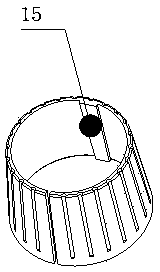

[0031] see figure 1 , a new type of tensioner, which includes: the tensioner includes a bottom housing 9, a spring 11 arranged in the housing, the tensioner also includes a tensioning arm 5, a central shaft 7, and the central shaft 7 is die-cast In the housing, which is integrated with the housing 9, the center of the tension arm 5 is provided with a center hole 13, and the center hole 13 is equipped with a self-lubricating bearing 6. The self-lubricating bearing 6 cooperates with the tension arm 5 to make the self-lubricating bearing 6 is pressed into the center hole of the tensioning arm 5, and the middle of the housing 9 and the tensioning arm 5 is provided with a nylon taper sleeve 8, and the tensioner also includes a pulley 1, a bearing 2, a bolt 3 and a dust cover 4 , the bolt 3 tightens the dust cover 4 and the bearing 2 on the tension arm 5, and the tightening torque of the bolt is 25±2.5N.m. When pressing in the self-lubricating bearing, the pressure head must be con...

Embodiment 2

[0033] see figure 1 , Figure 6 , as an improvement of the present invention, the spring is composed of a spring body 11 , an upper spring plane 17 and a lower spring plane 18 . Avoid the situation that the assembly is not in place during the assembly process. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0035] see figure 1 , Figure 5 , Figure 6 , Figure 7, as an improvement of the present invention, the bottom of the housing 9 is provided with a housing helical groove 19, the bottom of the tension arm 5 is provided with a tension arm helical groove 16, and the underspring plane 18 is connected to the bottom of the housing 9 The shell spiral groove 19, the spring upper plane 17 is connected to the spiral groove 16 of the tension arm 5, and the tension arm 5 and the shell 9 generate tension through the spring 11. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com