motorcycle led headlight

A technology for headlights and motorcycles, which is applied in the direction of headlights, motor vehicles, road vehicles, etc. It can solve the problem that the connection between the front part of the lamp housing and the main part does not have a waterproof effect, which affects the service life of LED lighting effects, and the headlights There are no problems such as heat dissipation structure, and the effect of convenient and fast lens installation, good waterproof effect, and convenient and fast installation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in combination with specific embodiments.

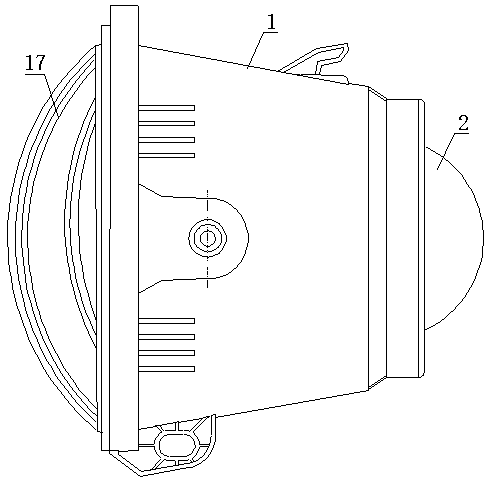

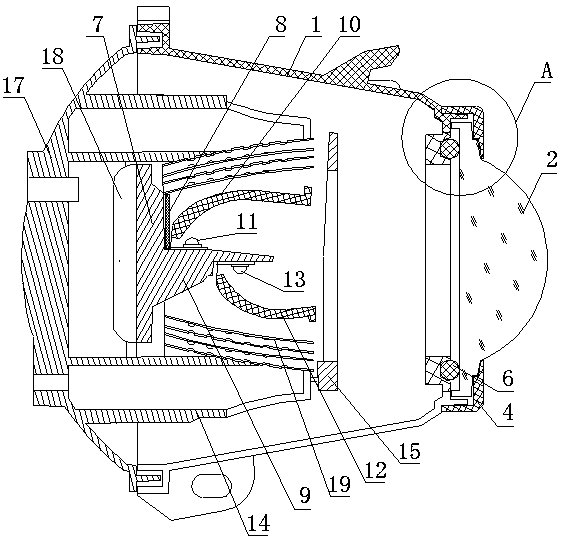

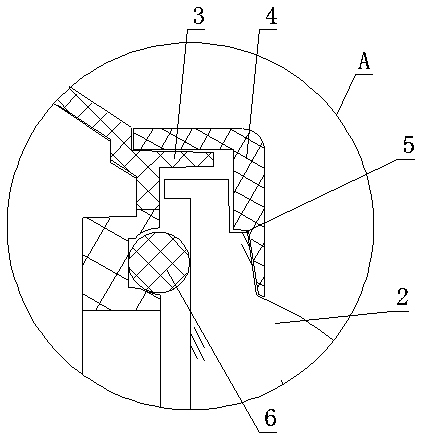

[0024] As a better implementation mode during specific implementation: such as Figure 1-Figure 3 As shown, a motorcycle LED headlight includes a lamp housing 1, a lens 2 located at the front end of the lamp housing 1 and an illumination structure located inside the lamp housing 1. The front end of the lamp housing 1 has a vertically arranged ring-shaped installation plane, the edge of the installation plane has a circle of installation edge 3 extending forward, the bottom of the lens 2 is installed on the installation plane, the periphery of the lens 2 has a ring-shaped waterproof decorative cover 4, and the waterproof decorative cover 4 has a circle along the horizontal The cylindrical part arranged in the direction, and the cylindrical part and the outer surface of the mounting edge 3 are threaded and are provided with a hot melt seal on the threaded surface. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com