Test device for bending vibration fatigue characteristics of ball-joint hanging rings in power transmission lines

A ball head hanging ring, testing device technology, applied in vibration testing, measuring device, using repetitive force / pulsating force to test the strength of materials, etc. It can simulate the operating conditions of the ball head hanging ring very well, and achieve the effects of accurate and stable bending vibration fatigue characteristics, accurate and reliable measurement results, and simplified data setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

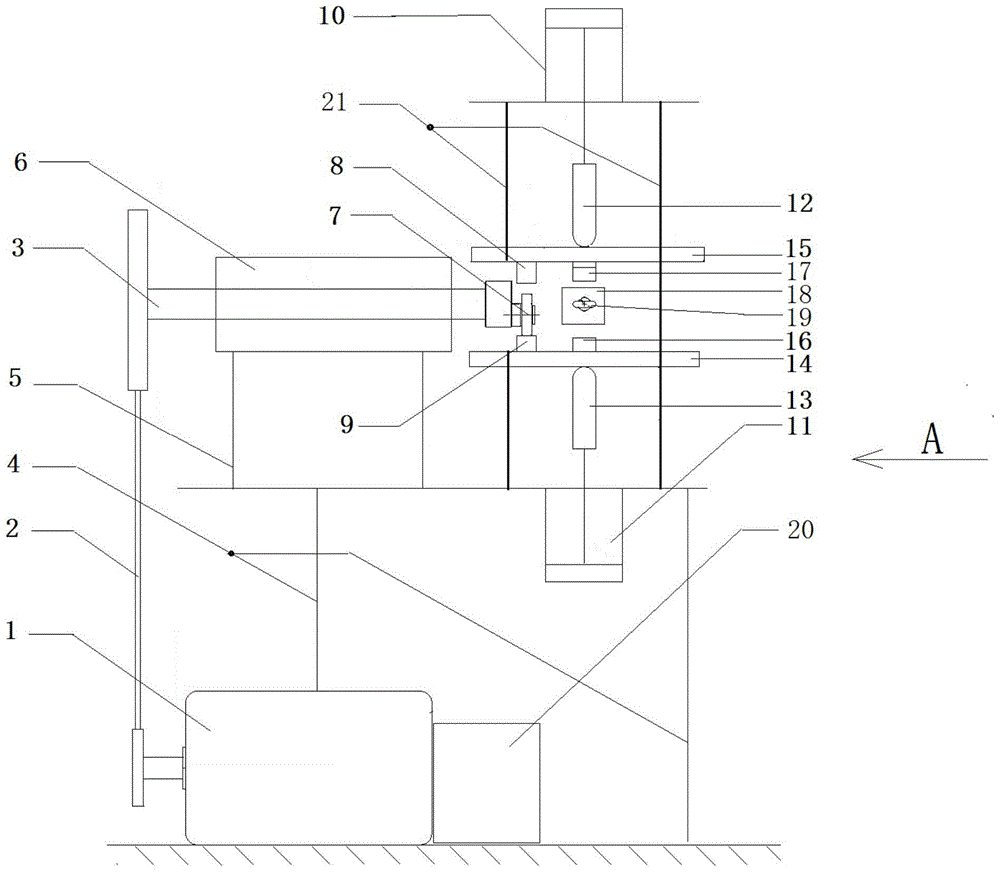

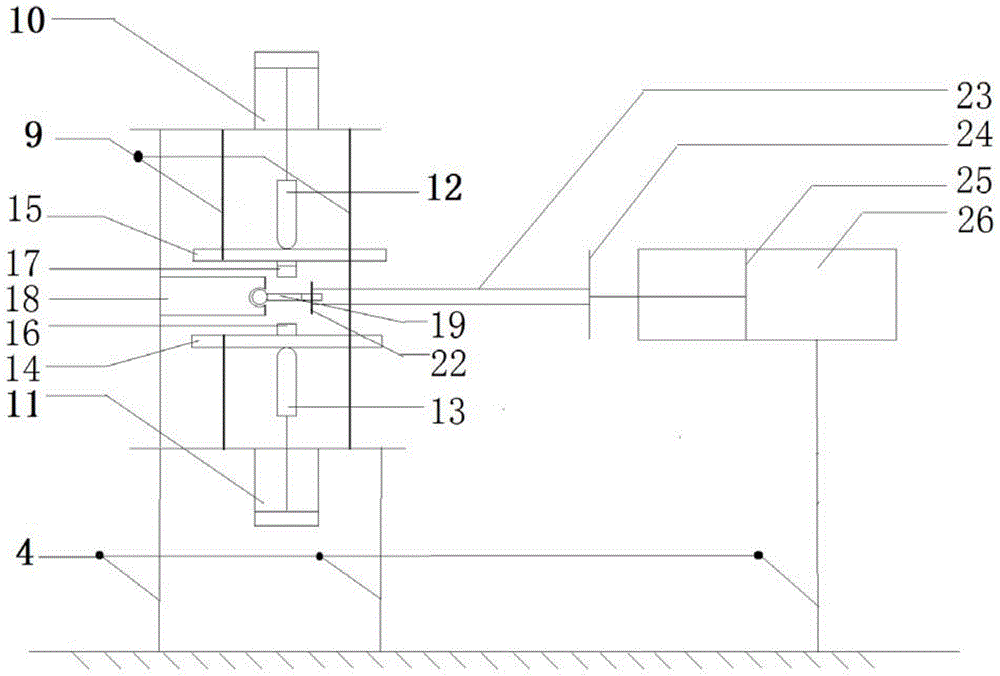

[0016] The test device for the bending vibration fatigue characteristics of the ball joint hanging ring in the power transmission line proposed by the present invention has a structure such as figure 1 As shown, it includes: motor 1, bearing 3, eccentric shaft top block 7, upper eccentric collision block 8, lower eccentric collision block 9, guide rail 21, upper cylinder 10, lower cylinder 11, upper cylinder ejector rod 12, lower cylinder ejector rod 13. Upper slider 15, lower slider 14, upper sample impact block 17, lower sample impact block 16, sample chuck 18, control panel 20, steel wire 23, steel wire connecting plate 24 and oil cylinder 26; The control panel 20 is connected with the input shaft of the motor 1, the output shaft of the motor is linked with the bearing 3 through the V-belt 2, the bearing 3 is placed in the bearing seat 6, the bearing seat 6 is placed on the bearing seat bracket 5, and the end of the bearing is provided with Eccentric shaft top block 7. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com