Method and platform for testing magnetic performance of laminated iron core of transformer in controllable excitation conditions

A test platform and transformer technology, applied in the direction of magnetic performance measurement, etc., can solve the problem that the performance data cannot truly reflect the real performance of the transformer core lamination material, and achieve the effect of a simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment, the present invention will be further described.

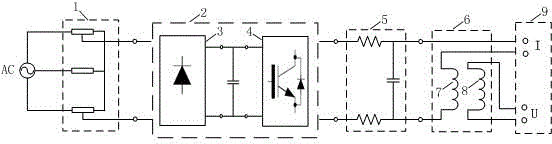

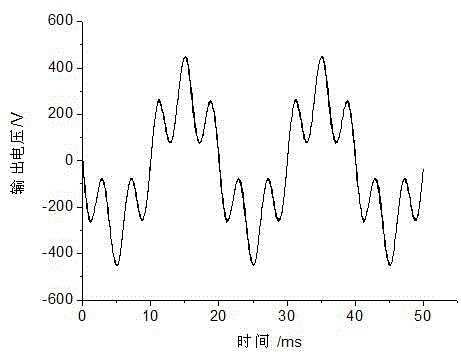

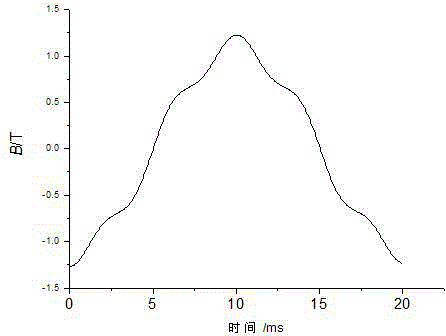

[0031] A transformer lamination core magnetic performance test platform with controllable excitation conditions, including a voltage regulator 1, a programmable frequency converter 2, an LC filter 5, a product-grade transformer core lamination model 6, and a power analyzer 9 connected in sequence; The programmable inverter 2 includes a rectification module 3 and an inverter module 4, and the product-grade transformer core lamination model 6 includes an iron core model excitation coil 7 and an iron core model measurement coil 8; the voltage regulator provides AC power supply for the input port of the programmable inverter Voltage, the computer controls the programmable frequency converter to output the required pulse voltage with equal amplitude and different width. After the pulse voltage is passed through the LC filter, the required arbitrary voltage waveform (bias or harmonic) is obtained, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com