Light guide plate and method for machining same

A processing method and technology of light guide plate, applied in metal processing equipment, optics, light guide, etc., can solve problems such as interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

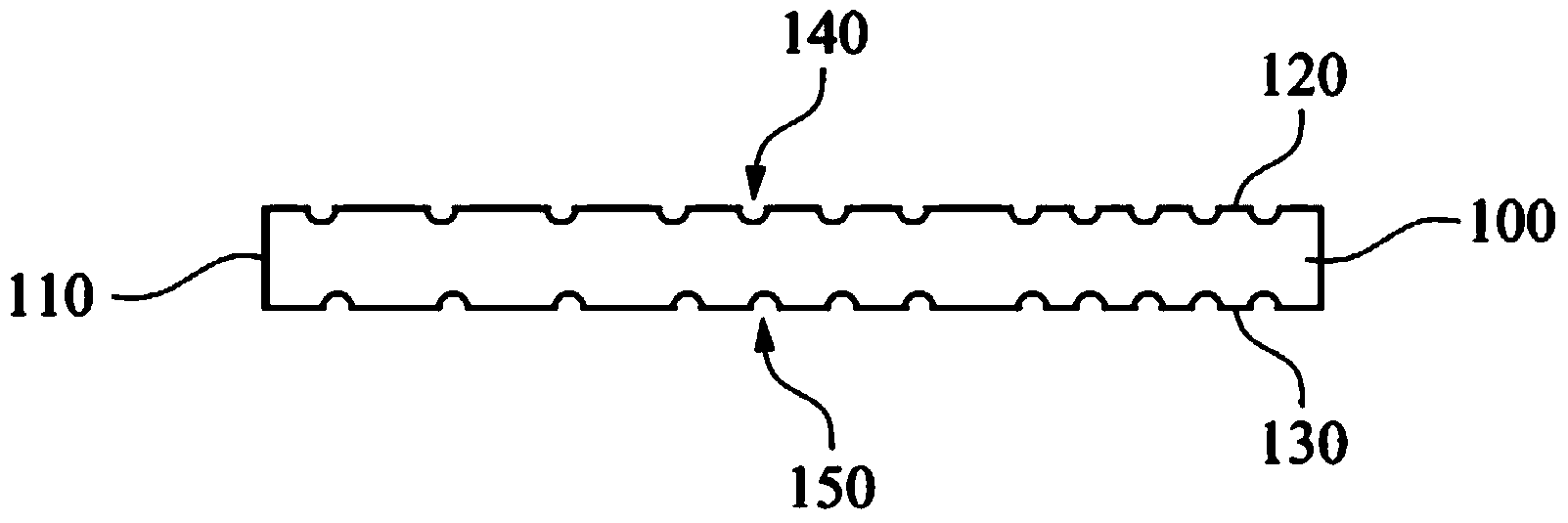

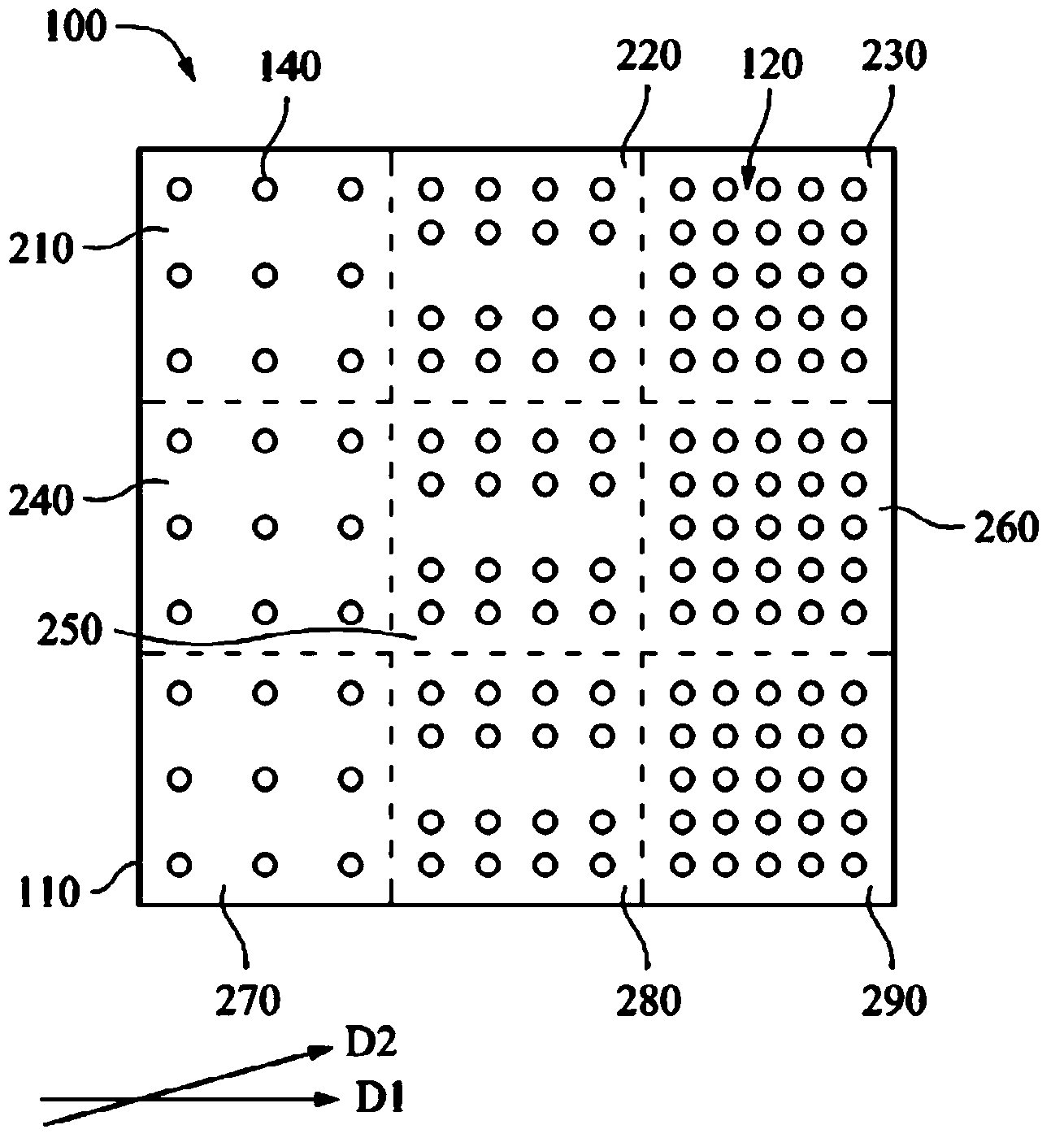

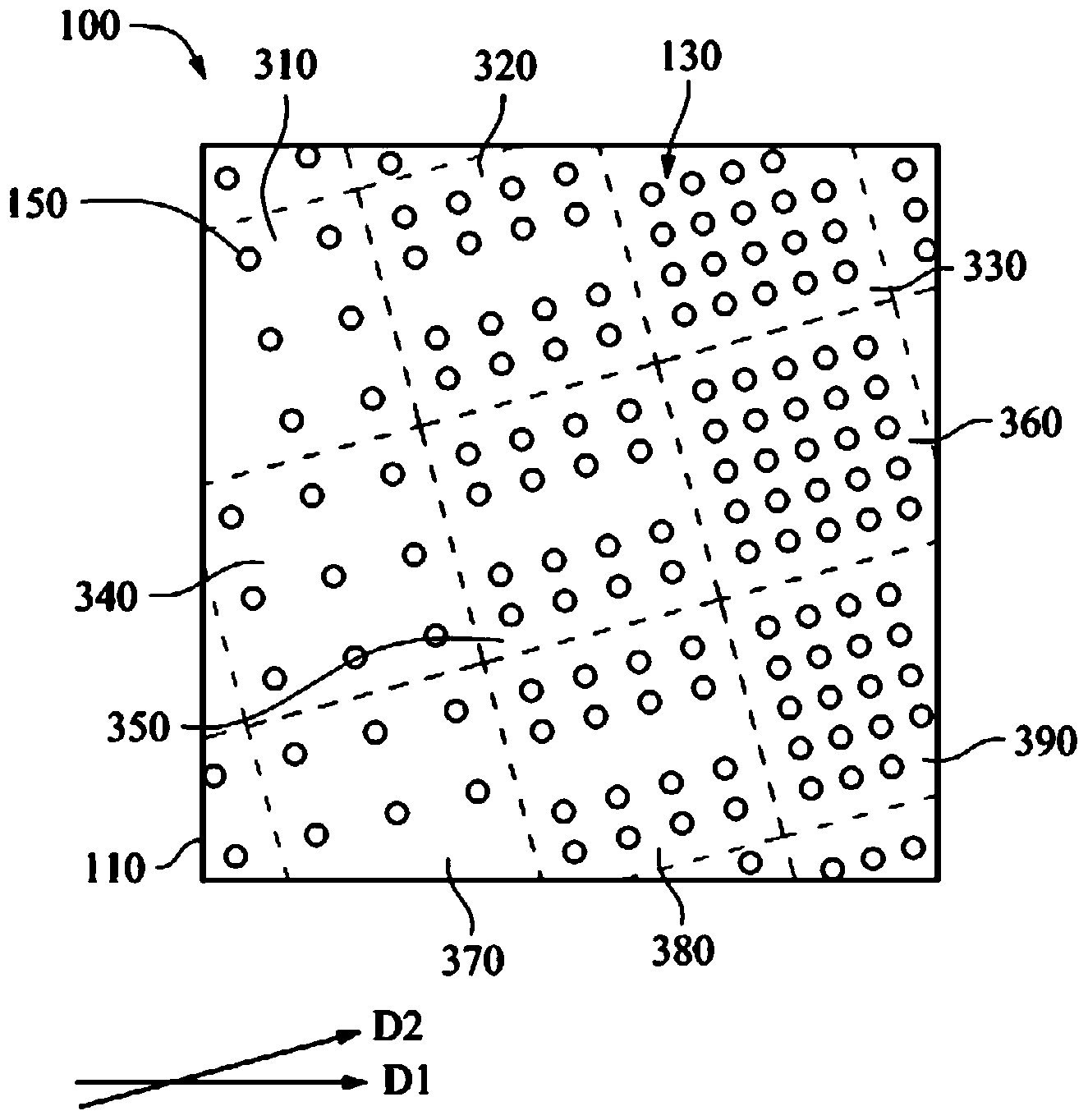

[0052] refer to figure 1 , figure 1 It is a side view of the light guide plate 100 in one embodiment of the present invention. This embodiment provides a light guide plate 100 , including a light incident side 110 , an upper surface 120 , a lower surface 130 , a first microstructure pattern 140 , and a second microstructure pattern 150 . The upper surface 120 is connected to the light incident side 110 . The lower surface 130 is connected to the light-incident side 110 and is disposed relative to the upper surface 120 . The first microstructure pattern 140 is disposed on the upper surface 120 . The second microstructure pattern 150 is disposed on the lower surface 130 .

[0053] In one or more embodiments of the present invention, the first microstructure pattern 140 and the second microstructure pattern 150 can be a plurality of dot-shaped raised or depressed microstructures, and the first microstructure pattern 140 and the second microstructure pattern The light-trappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com