Method and device for changing filter cartridge

A filter element and updated technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of labor cost, low judgment accuracy, waste of resources, etc., to save labor costs, improve operation efficiency, The effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

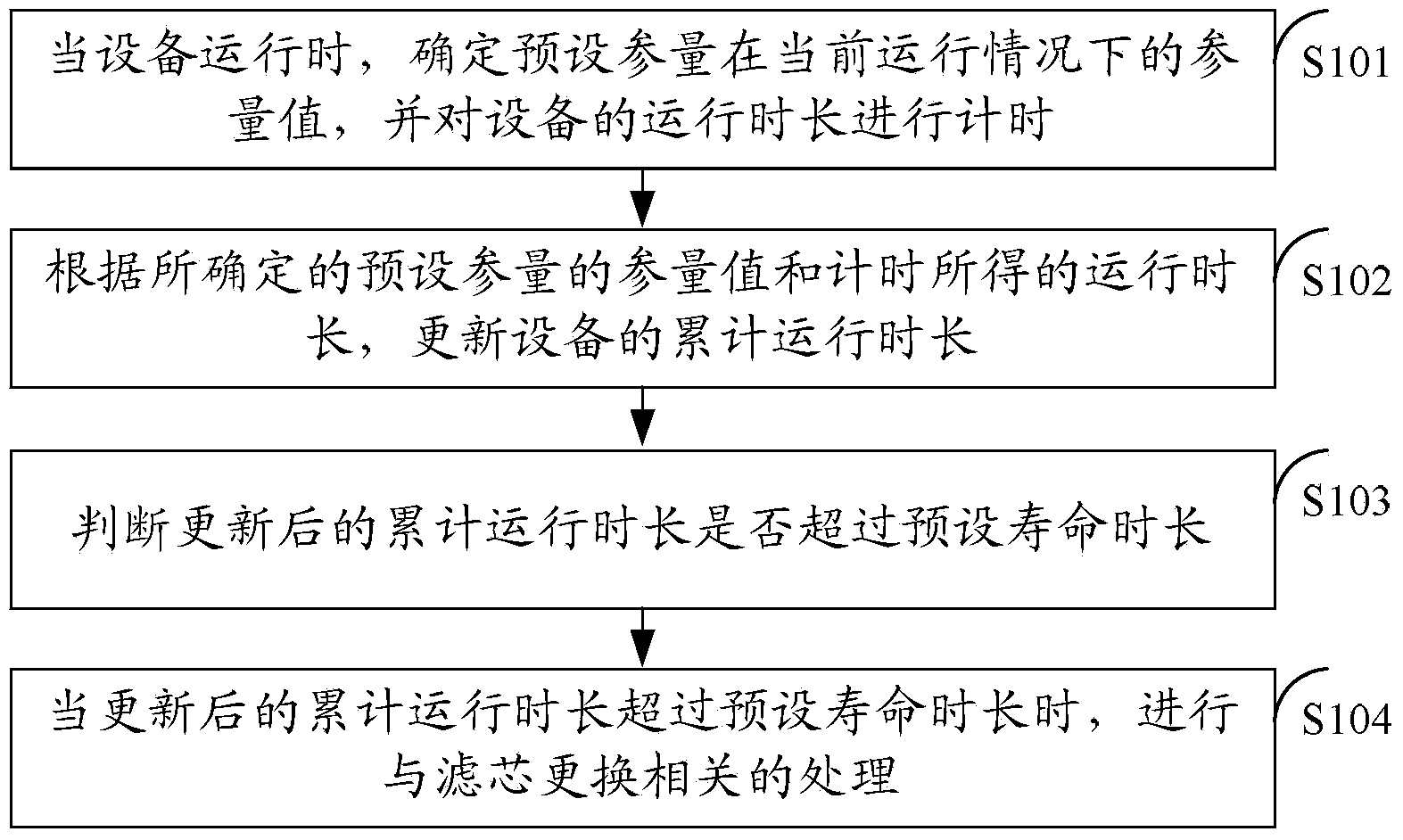

Method used

Image

Examples

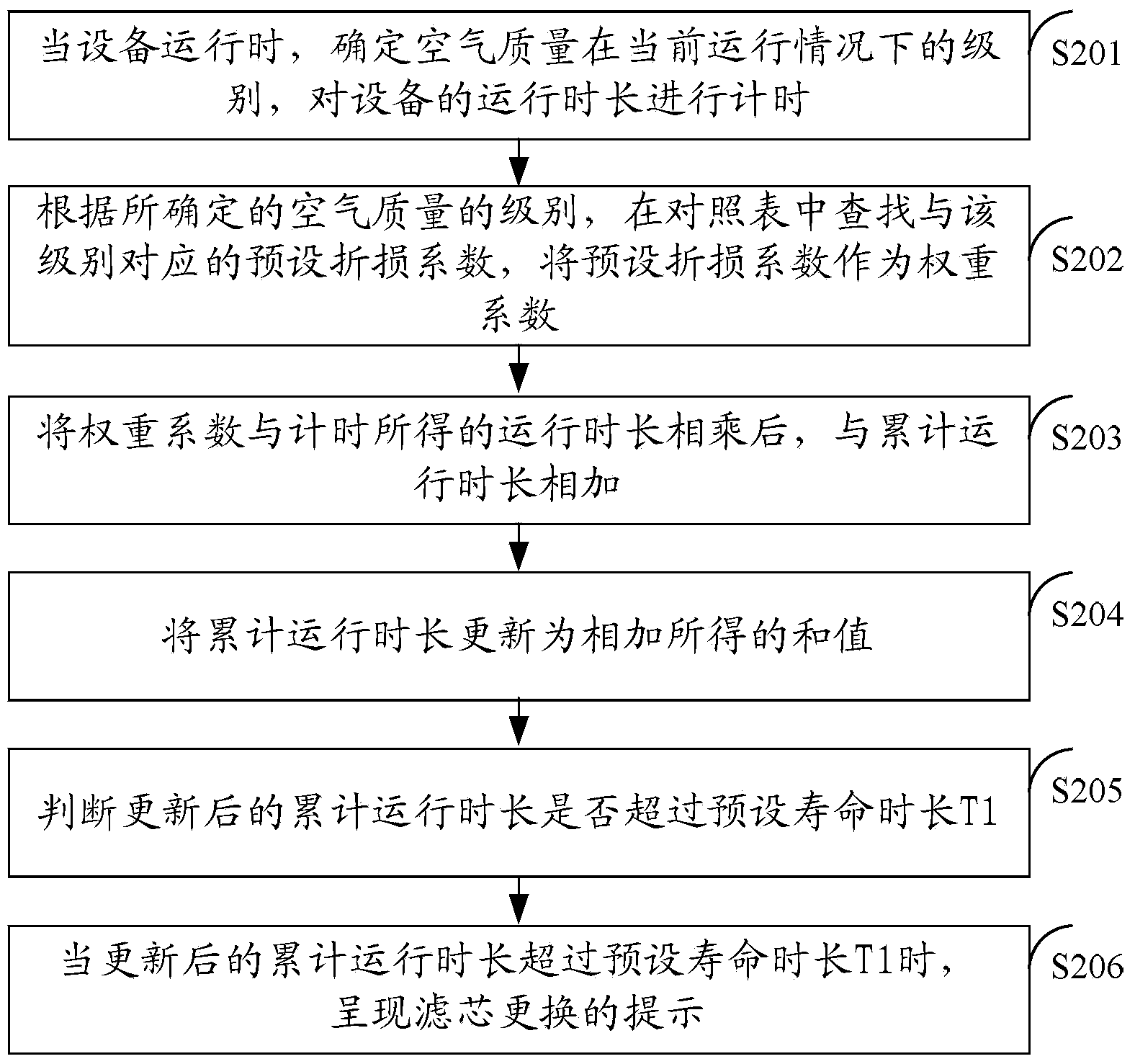

Embodiment 1

[0115] figure 2 It is a flowchart of a method for replacing a filter element according to an exemplary embodiment 1. Such as figure 2As shown, the method for replacing the filter element is used in equipment with filter elements, such as air conditioners, air purifiers, and automobiles. The application scenario of Embodiment 1 is: the preset parameter is air quality, and the air quality is divided into three levels, namely excellent, good, and poor; when the air quality is excellent, the preset life span is measured as T1; Comparison table, three levels of air quality are stored in the comparison table, and the preset loss coefficients corresponding to the three levels are K 优 、K 良 、K 差 , set K 优 = 1,K 良 =1.5,K 差 =2. The method in embodiment one comprises the steps:

[0116] In step S201, when the device is running, determine the level of the air quality under the current running condition, and count the running time of the device.

[0117] In step S202, according ...

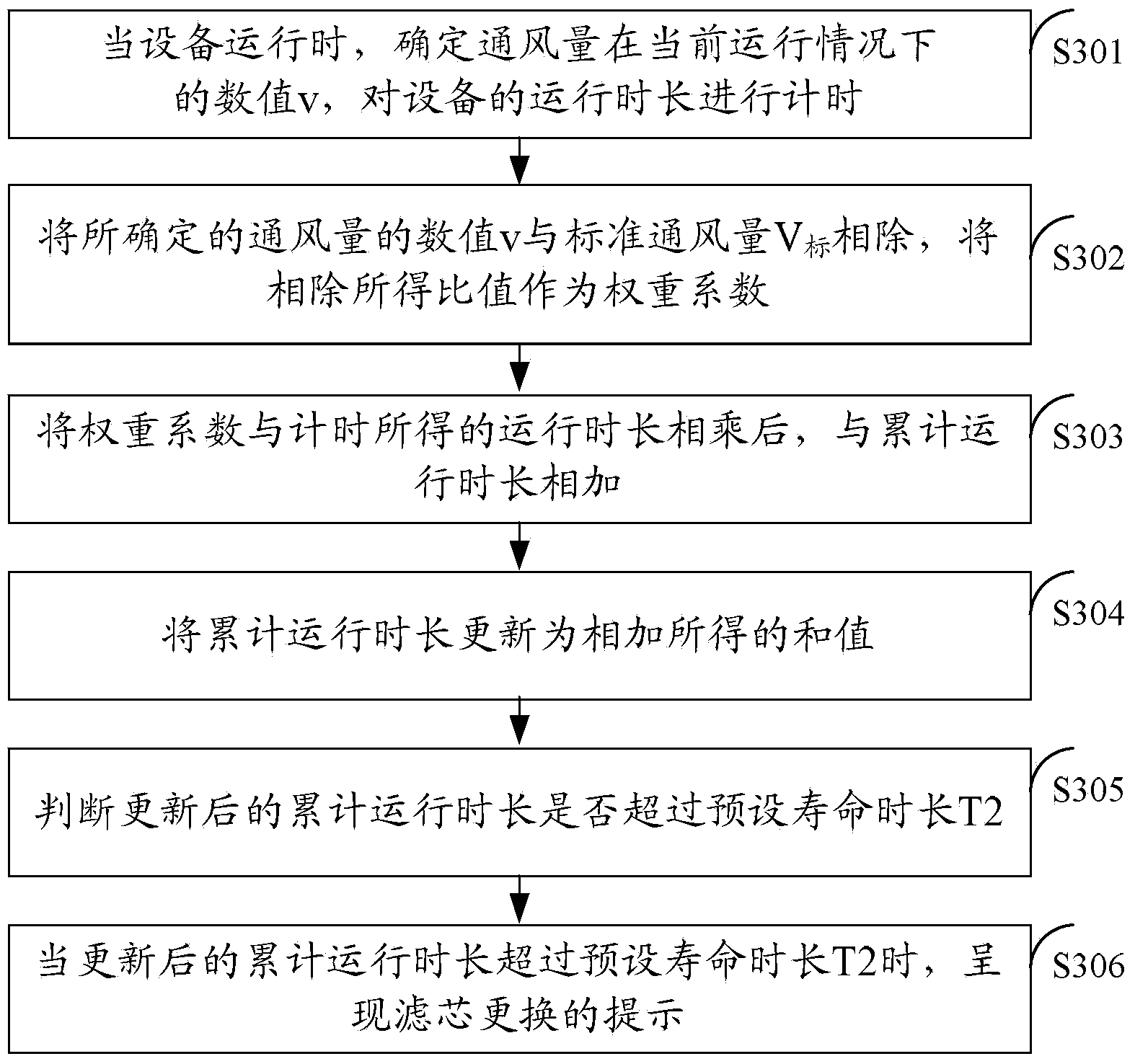

Embodiment 2

[0124] image 3 It is a flowchart of a method for replacing a filter element according to a second exemplary embodiment. Such as image 3 As shown, the method for replacing the filter element is used in equipment with filter elements, such as air conditioners, air purifiers, and automobiles. The application scenario of the second embodiment is: the preset parameter is the ventilation rate, the ventilation rate is a specific value, and the standard ventilation rate V 标 In the case of , the measured preset life span is T2. The method in embodiment two comprises the steps:

[0125] In step S301, when the device is running, the value v of the ventilation rate under the current running condition is determined, and the running time of the device is counted.

[0126] In step S302, the value v of the determined ventilation volume and the standard ventilation volume V 标 The ratio obtained by the division is used as the weight coefficient.

[0127] Among them, the weight coefficie...

Embodiment 3

[0134] Figure 4 It is a flowchart of a method for replacing a filter element according to a third exemplary embodiment. Such as Figure 4 As shown, the method for replacing the filter element is used in equipment with filter elements, such as air conditioners, air purifiers, and automobiles. The application scenario of Embodiment 3 is: the preset parameters include: air quality, ventilation rate and purification rate; the air quality is divided into three levels, namely excellent, good and poor; the ventilation rate and purification rate are divided into specific values; When the air quality is excellent and the standard ventilation volume V 标 and the standard ventilation volume P 标 In the case of , the measured preset life span is T3; a comparison table is stored, which stores three levels of air quality and the preset loss coefficients corresponding to the three levels, which are K 优 、K 良 、K 差 , set K 优 = 1,K 良 =1.5,K 差 =2. The method in embodiment three comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com