Heating device for stainless steel blackening

A technology of blackening treatment and heating device, which is applied in immersion heating device, metal material coating process and other directions, can solve the problems of high energy consumption, lack of heating, heat preservation links, and increase in cost, and achieves increased heating service life, The effect of reducing maintenance costs and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

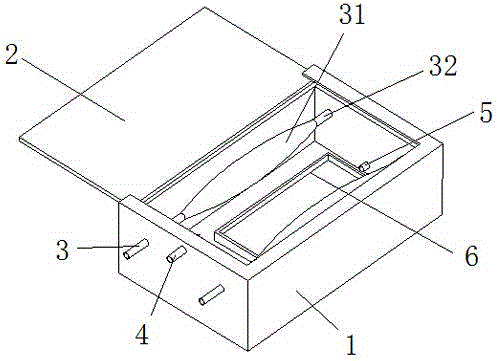

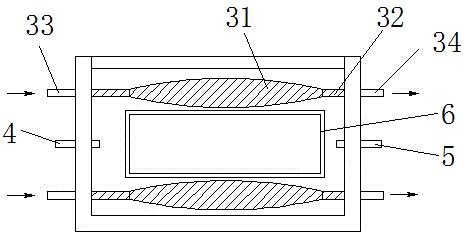

[0021] Example 1, such as Figure 1-2 As shown, a stainless steel blackened heating device includes a box body 1 with an open upper end and a cover plate 2 for closing the opening of the box body 1, and the cover plate 2 is connected to the box body 2 by plugging. When the stainless steel pipe was blackened, the cover plate 2 was in the state of sealing the casing 1 to ensure that the heat would not be lost. Two heating pipes 3 are arranged near the inner wall of the box 1, and the two heating pipes 3 are respectively arranged on opposite sides of the box 1, and the distance between one of the heating pipes 3 and the bottom surface of the box 1 is greater than The distance between another heating pipe 3 and the bottom surface of the box body 1 . Both ends of the heating pipe 3 extend outwards and pass through the casing 1 to form an inlet 33 and an outlet 34; an insulating layer 32 is arranged on the outer surface of the heating pipe 3, and the insulating layer 32 here can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com