Device for pressing the yarn onto the bobbin

A bobbin and yarn technology, applied in the direction of transportation and packaging, bearings for rotational motion, rigid supports for bearing components, etc., can solve problems such as unfavorable stability of bobbin mandrels, different, uneven loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

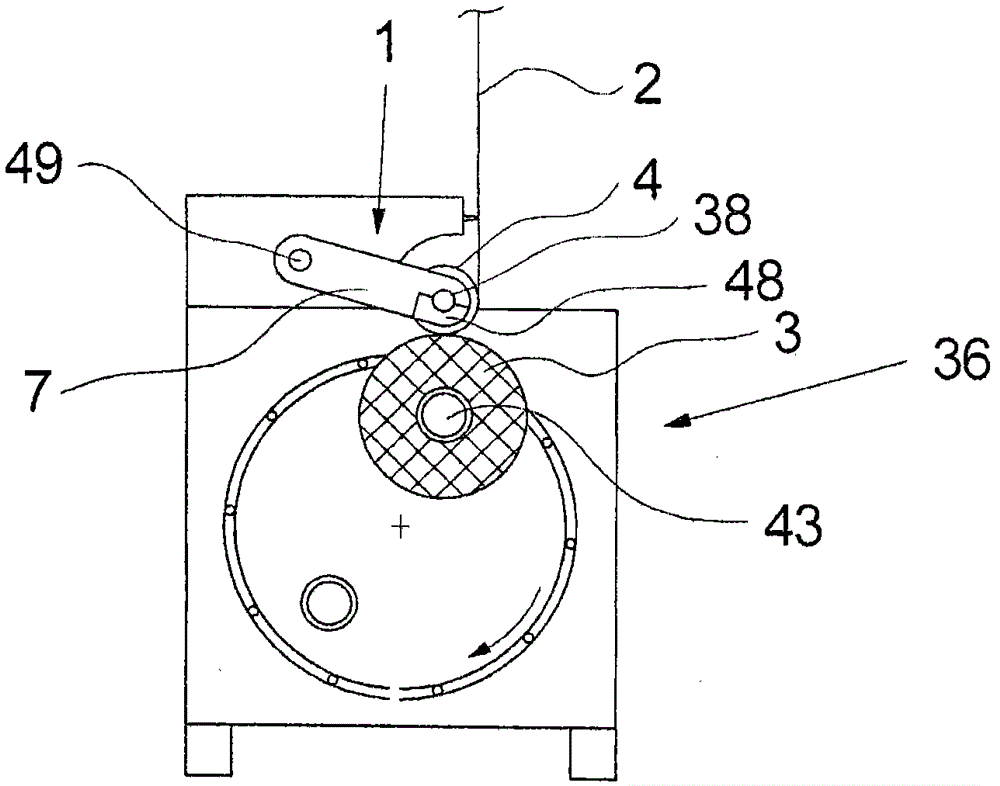

[0024] figure 1 Shown is a winder 36 with a device 1 for pressing the yarn 2 onto the bobbin 3 . The device 1 comprises a pressure roller 4 connected to a winder 36 by means of a movable roller support 7 . The roller carrier 7 is designed as a rocker arm which is held on the winder 36 via a pivot bearing 49 . The press roller 4 is held at the free end of the roller bracket 7 . The pressing roller 4 presses the yarn 2 onto the surface of the bobbin 3 , which is rotatably mounted on the bobbin mandrel 43 .

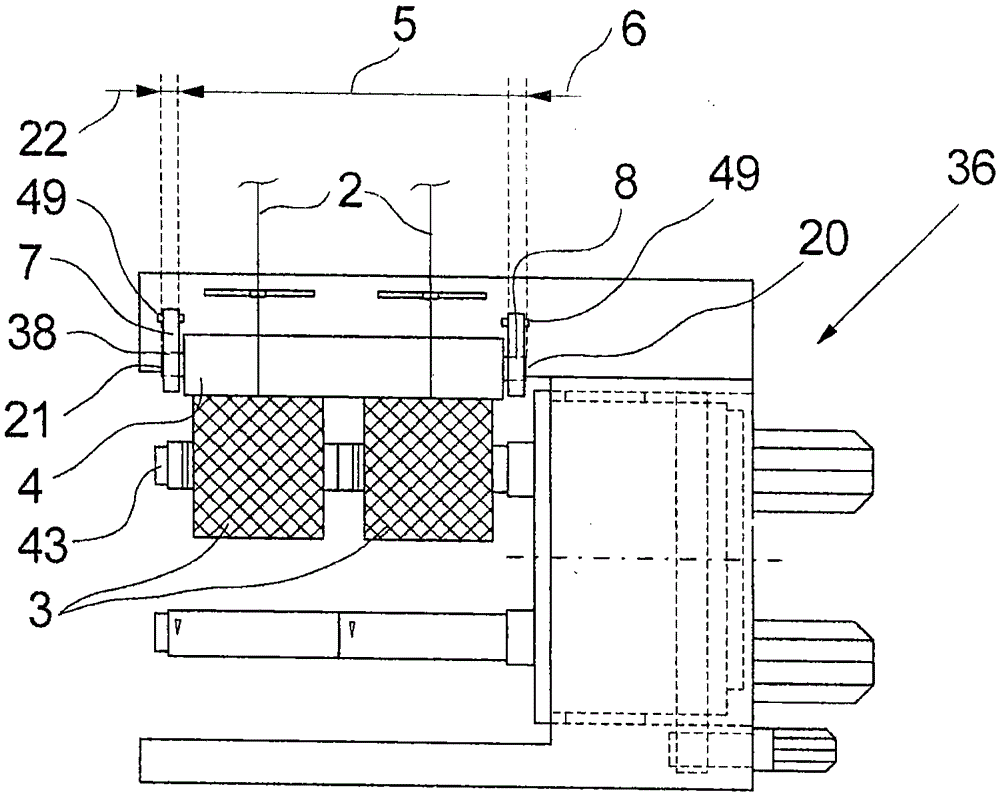

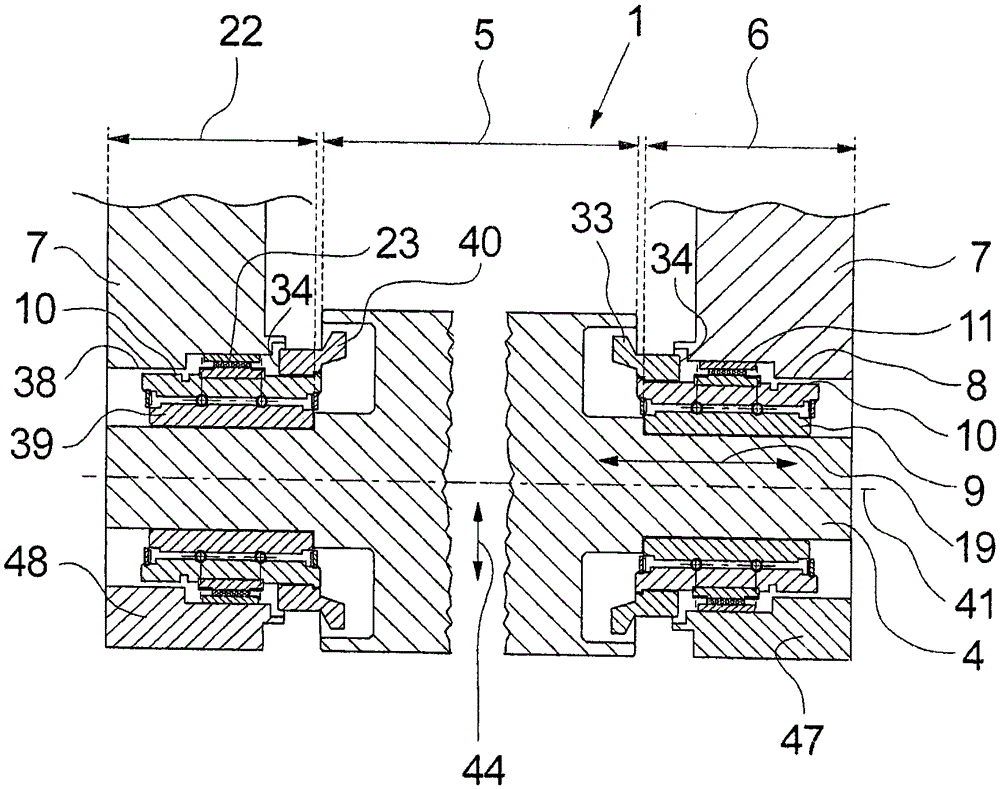

[0025] figure 2 show figure 1 Side view of the winder 36. It can be seen that the pressure roller 4 has a yarn guide 5, in which two yarns 2 are each wound onto a bobbin 3. Furthermore, the pressure roller 4 comprises a first bearing part 6 at the first end 20 which is mounted in a first receptacle 8 of the roller holder 7 . Furthermore, the pressure roller 4 comprises a second bearing part 22 at the second end 21 which is mounted in a second receptacle 38 of the rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial stiffness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com