Flue gas collection device with multiple rows of staggered diversion tube bundles and triangular expansion cover

A technology of flue gas collection and guide pipe, which is applied in the direction of dust removal, cleaning methods and utensils, and separation of dispersed particles. It can solve the problems of increased dust content and high speed in the exhaust hood, and achieve good dust suppression and dust reduction. The effect of changing the characteristics of the flow field and uniform velocity distribution of the cross-flow section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

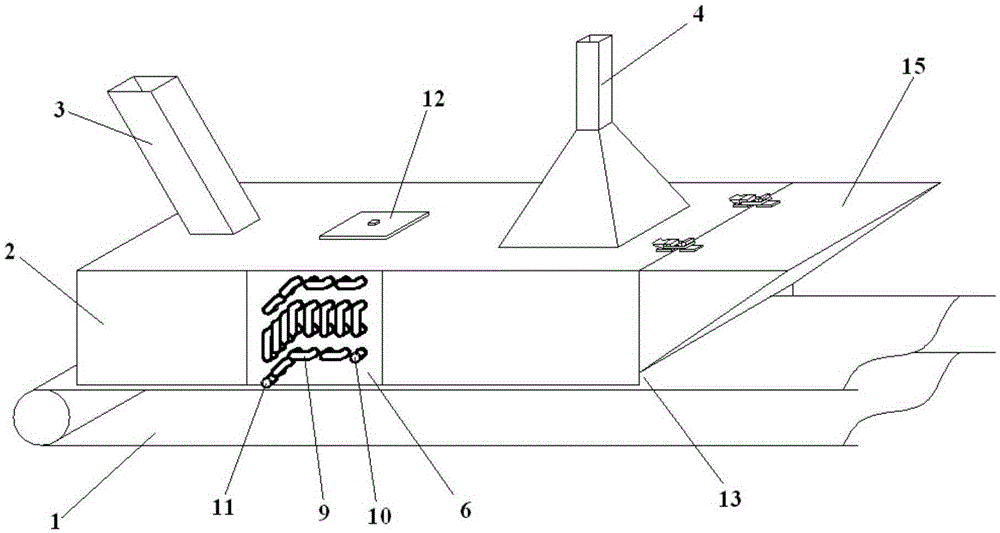

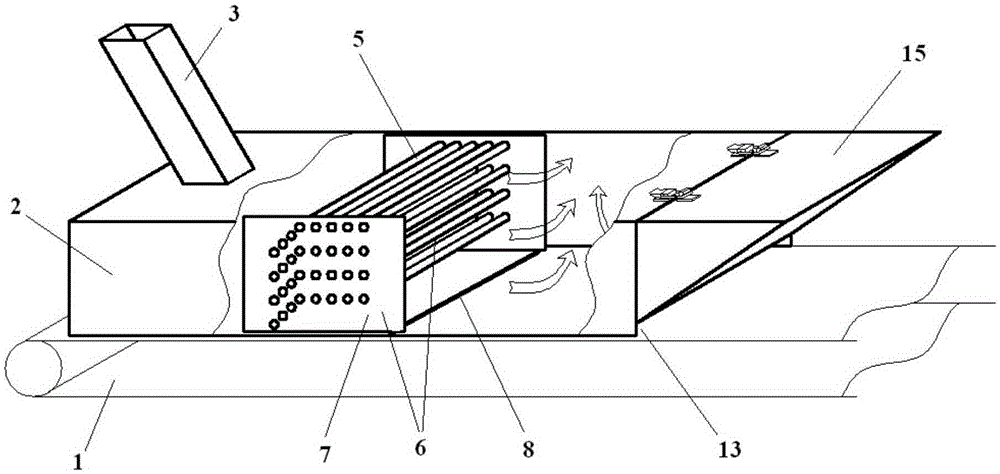

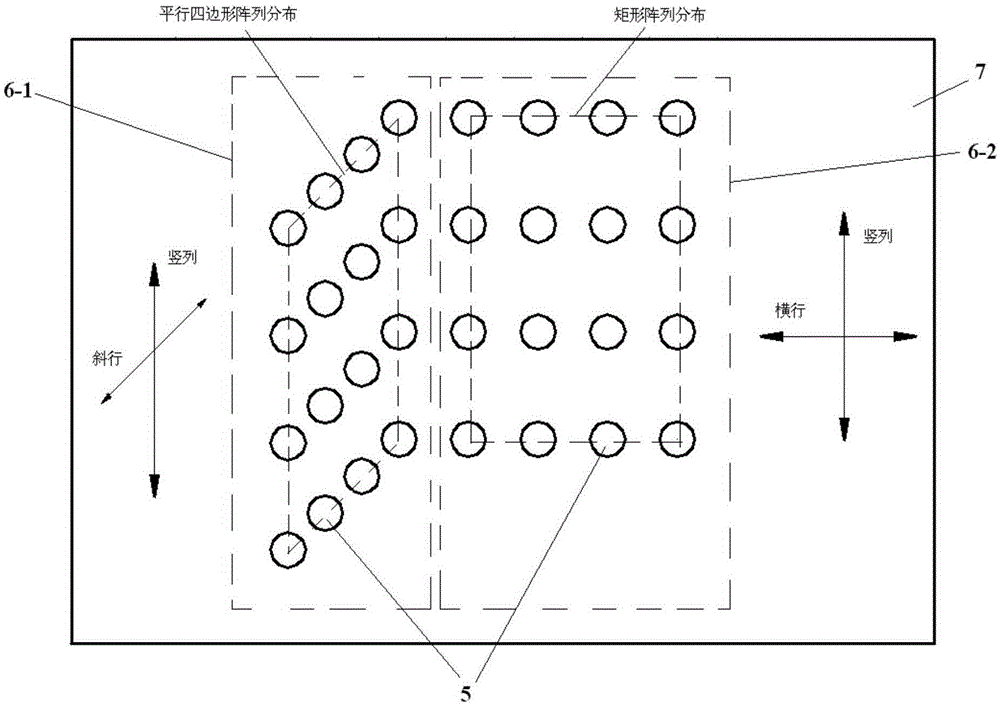

[0071] In order to overcome the technical deficiencies in Comparative Document 1, such as Figure 1 to Figure 5 As shown, the present embodiment provides a flue gas collection device, including an exhaust hood 2 arranged above the conveyor belt 1, the exhaust hood 2 is provided with a feeding port 3 and a draft port 4, and the feeding port 3 and the exhaust port The interior of the exhaust hood 2 between the ports 4 is equipped with a detachable multi-row staggered diversion tube bundle 6 composed of diversion tubes 5, and the diversion tubes 5 are perpendicular to the running direction of the material on the conveyor belt 1;

[0072] The cross-sectional layout of the multi-row staggered diversion tube bundle 6 is divided into two areas, the area near the discharge port 3 is the stop guide area 6-1, and the area near the air outlet 4 is the post-settlement and flow stabilization area 6-2;

[0073] The stop guide front area 6-1 is used for multiple collisions and frictions to ...

Embodiment 2

[0090] This embodiment provides a flue gas collection device, the other structures are the same as in Embodiment 1, the difference is that the guide tube 5 is a hollow tube, and the end of the guide tube 5 protruding from the tube plate is connected through an adapter 9 , an inlet 10 and an outlet 11 are reserved, and the entire multi-row staggered guide tube bundle 6 forms a connected pipeline, and heating agent or refrigerant can be passed into the guide tube 5 to realize the internal ventilation of the exhaust hood 2 Heating or cooling, such as hot water or cold water, can better collect flue gas for some materials with special temperature requirements. The equipment can not only reduce dust and suppress dust, but also play a role in cooling, recovering waste heat and reusing it, which can meet the requirements of energy saving.

Embodiment 3

[0092] This embodiment provides a smoke collection device, other structures are the same as in Embodiment 1, the difference is that the end surface of the exhaust hood 2 close to the feeding opening 3 is closed, and the end surface of the exhaust hood 2 close to the air outlet 4 is also closed But this end face is provided with discharge opening 13 near the side of conveyer belt 1, and the exhaust hood 2 closed end surface of the top of discharge opening 13 is processed with expansion opening 14, and the sealing cover on expansion opening 14 is closed with triangular expansion cover 15, triangular expansion cover 15. The right-angled surface of the expansion cover 15 in contact with the expansion opening 14 is open, and the other right-angled surface of the triangular expansion cover 15 is flush with the top surface of the exhaust hood 2 . The included angle between the triangular expansion cover 15 and the top surface of the exhaust hood 2, which is flush with the right-angled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com