Multifunctional material receiving box and shift conveying device applied to cup making machine

A technology of conveying device and receiving box, which is applied in the directions of packaging, object stacking, transportation and packaging, etc. It can solve the problems that the automatic conveying bagging unit cannot be directly applied, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

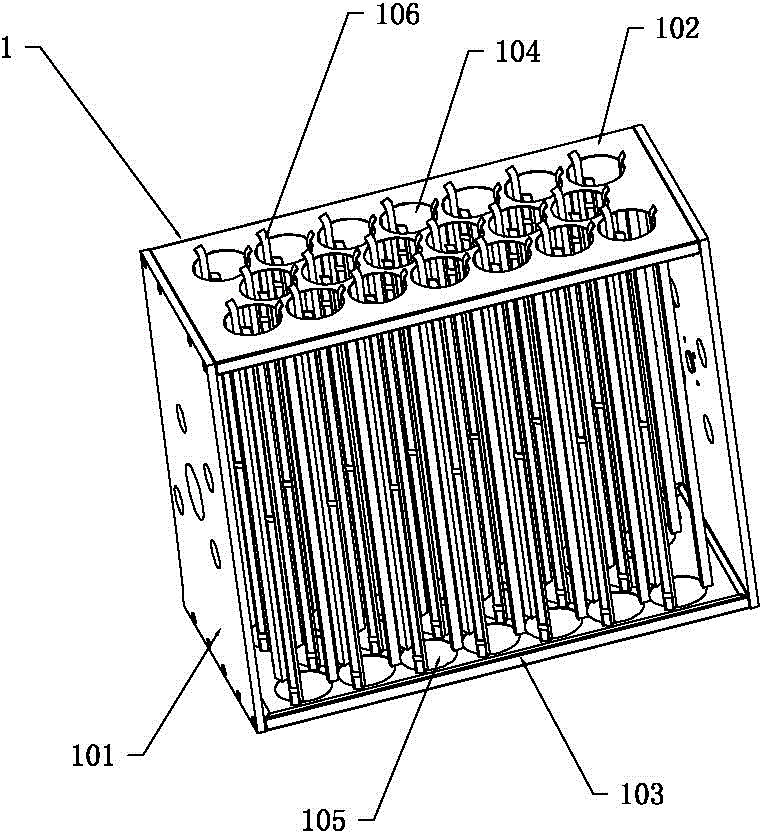

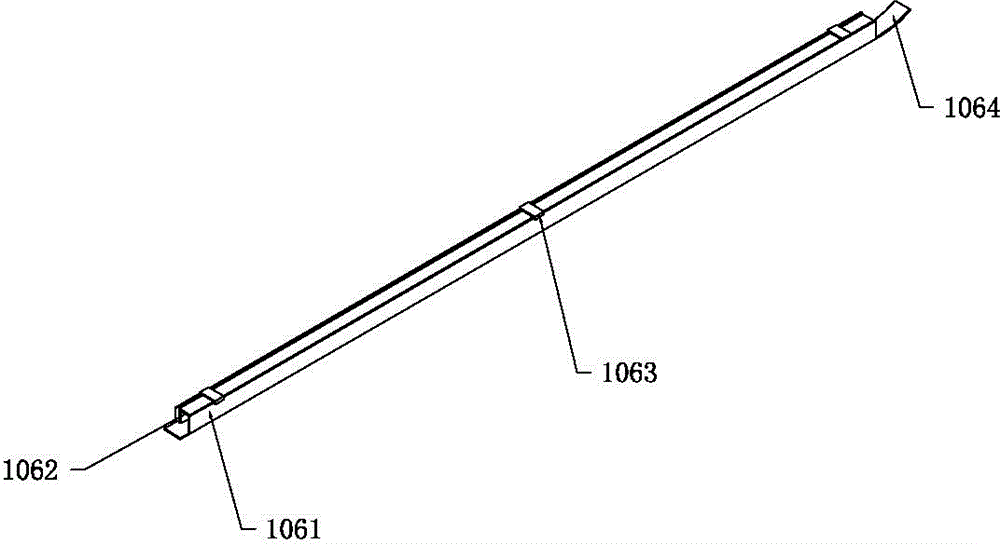

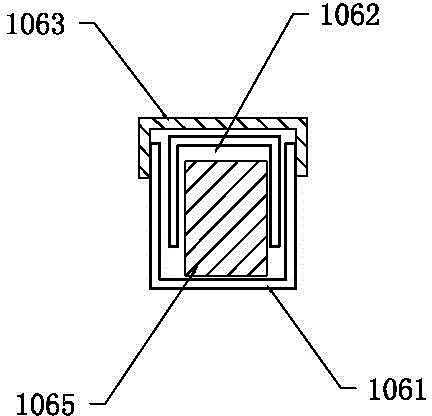

[0066] Such as figure 1 As shown, the multi-functional material receiving box 1 applied to the cup making machine in this embodiment is provided with multiple rows of material receiving units, each row of material receiving units includes a plurality of material receiving chambers, the number of rows of material receiving units and the number of each row of material receiving units. The number of the material receiving chambers of the material receiving unit can be set to different numbers according to actual needs. In this embodiment, the multifunctional material receiving box 1 is provided with three rows of material receiving units, and the material receiving chambers of two adjacent rows of material receiving units Staggered settings. Each material receiving chamber is provided with a material receiving port 104, a discharge port 105 and at least three evenly distributed elastic transmission limit rods 106, and each material receiving chamber is provided with a material r...

Embodiment 2

[0079] The main technical scheme of a multi-functional receiving box and shifting transmission device applied to a cup making machine in this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are adopted in Embodiment 1. explanation, and will not repeat them here. The difference between this embodiment and Embodiment 1 lies in that the support plate 102 of the material inlet and the support plate 103 of the discharge port of this embodiment are fixedly connected with the box frame plates 101 on both sides, and are an integrally formed structure.

Embodiment 3

[0081] The main technical scheme of a multi-functional receiving box and shifting transmission device applied to a cup making machine in this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are adopted in Embodiment 1. explanation, and will not repeat them here. In this embodiment, on the basis of Embodiment 1, a buffer brush is provided on the edge of the material receiving port 104. The function of the buffer brush is to buffer the plastic container, especially the lighter cover, directly falling into the material receiving limit channel. The buffer brush first Undertake a small amount of shallow-bottomed light-weight plastic containers. When the small stack of shallow-bottomed light-weight plastic containers reaches a certain weight, they will use their own weight to fall into the material-receiving limit channel, so as to ensure that the shallow-bottom light-weight plastic containers are in the material-receiving l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com