A furry device

A technology of wool device and wool box, which is applied in textiles and papermaking, fiber treatment, fiber mixing, etc., can solve the problems of less mixing amount and uneven mixing, and achieve good effect, good effect and high wool efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

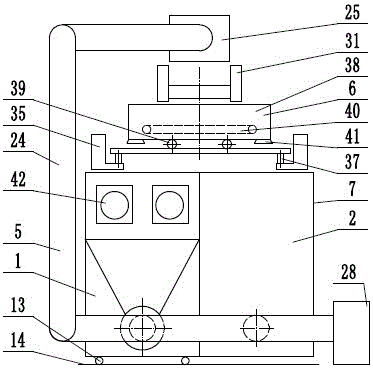

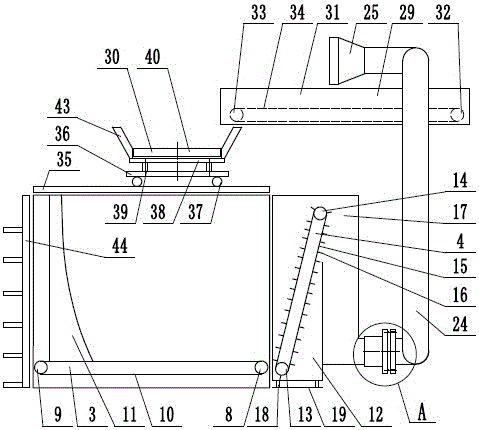

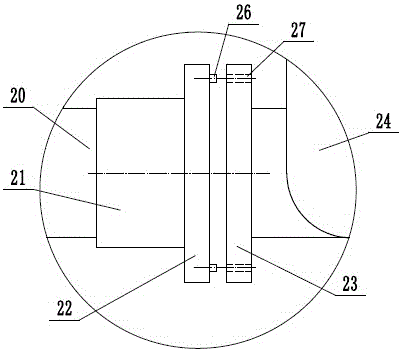

[0017] like figure 1 , figure 2 and image 3As shown, a wool blending device includes a left wool blending box 1, a right wool blending box 2, a horizontal conveying mechanism 3, an inclined conveying mechanism 4, an air pressure conveying mechanism 5, a nodding mechanism 6, a closed door 7, and a horizontal conveying mechanism 3 The wool in the left and wool box 1 or the right wool box 2 is conveyed horizontally forward, and the inclined conveying mechanism 4 realizes the horizontally conveyed wool and wool to be transported obliquely upward, and falls down into the noil box 17 for uniform mixing , the air pressure transmission mechanism 5 uses air pressure to transport the wool through the hair delivery pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com