Control system for automatic overlock stitch production device

A production device and control system technology, which is applied in the direction of program-controlled sewing machines, textiles and papermaking, sewing equipment, etc., to achieve the effects of low cost, wide application and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

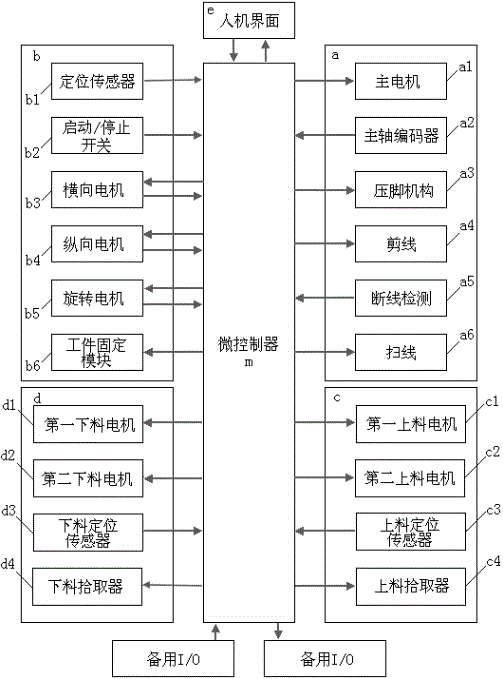

[0023] Reference figure 1 As shown, a control system of an automatic seaming production device includes a microcontroller m, and the main motor a1 of the seaming machine a1, a spindle encoder a2, a presser foot mechanism a3, and a scissors are connected to the microcontroller m. Line a4, line sweeping a6, disconnection detection a5, lateral motor b3, longitudinal motor b4, rotating motor b5, positioning sensor b1, start / stop switch b2, workpiece fixing module b6, and the first part of the feeding device c A feeding motor c1, a second feeding motor c2, a feeding positioning sensor c3, a feeding picker c4, a first feeding motor d1, a second feeding motor d2, and a feeding positioning sensor d3 of the feeding device d Unloading picker d4, and man-machine interface e.

[0024] The main motor a1, the transverse motor b3, the longitudinal motor b4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com