Door hinge for washing machine

A technology for door hinges and washing machines, applied in the field of door hinges, can solve problems such as difficult assembly methods and complex spring structures, and achieve the effects of low manufacturing unit price, easy assembly, and simple action principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

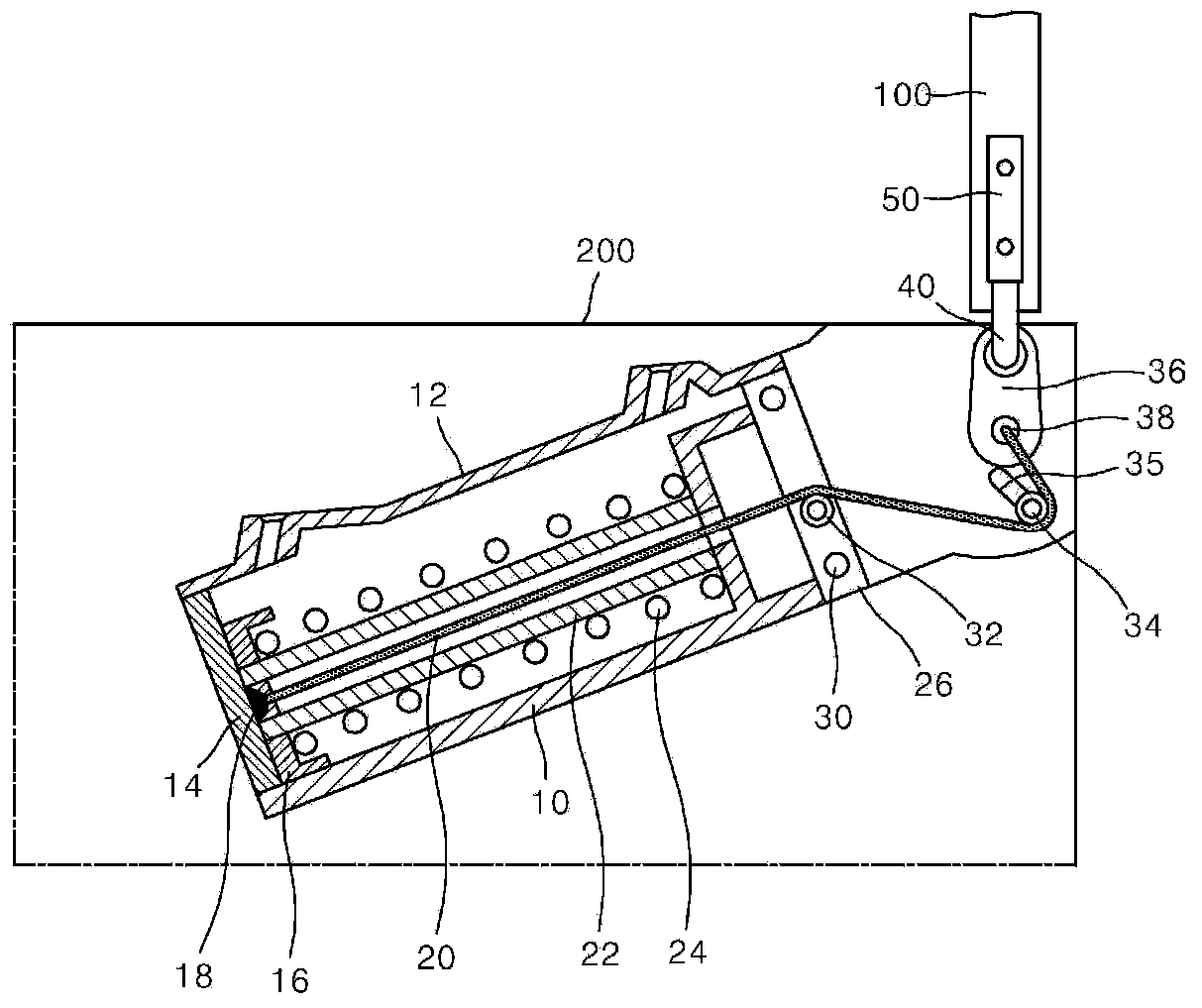

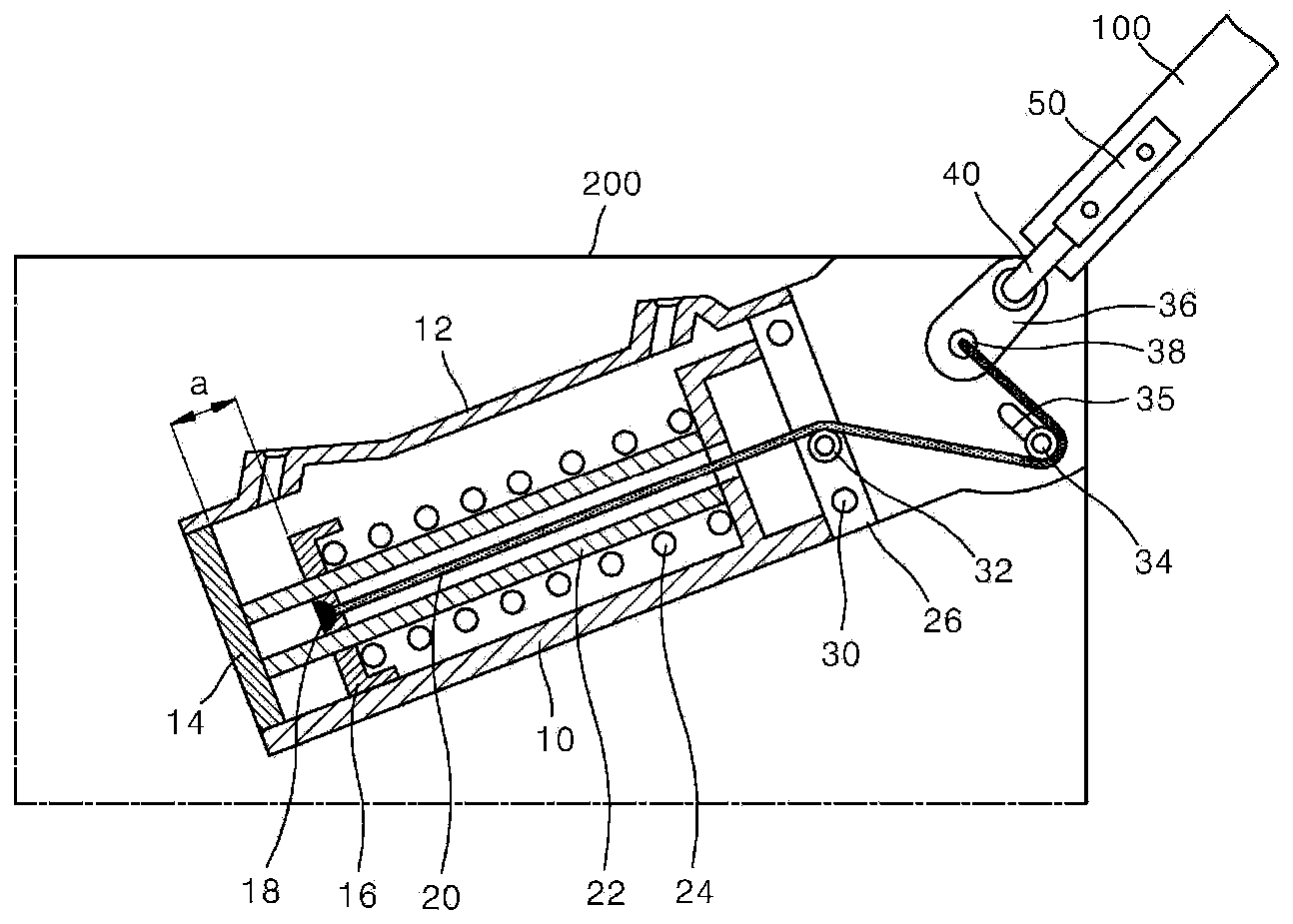

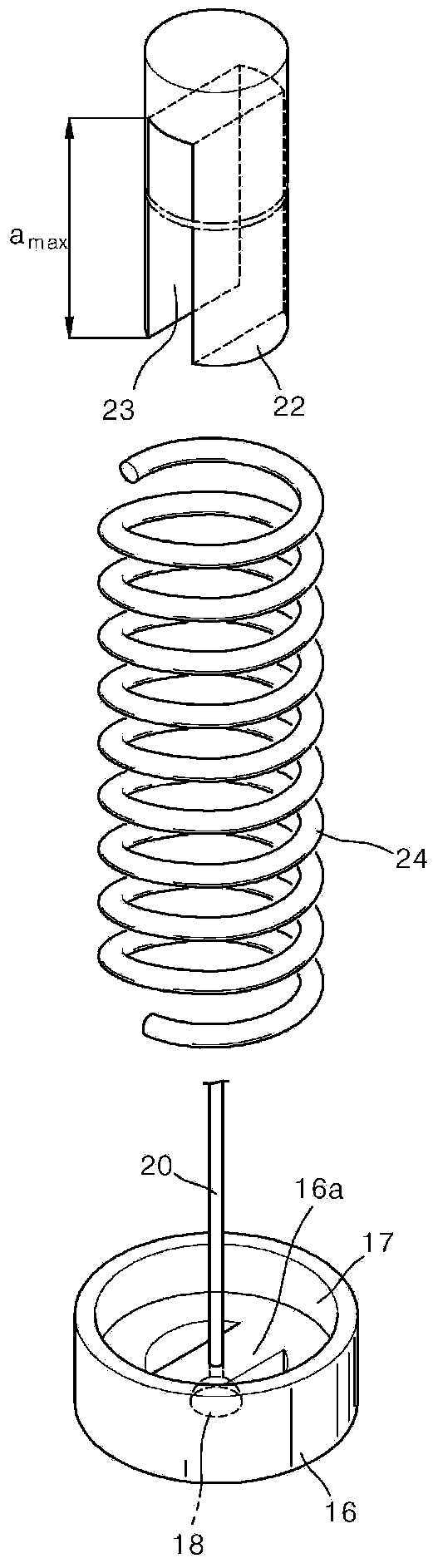

[0012] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments described below can be changed into various other forms, and the scope of the present invention is not limited to the embodiments described below. The embodiments of the present invention are presented in order to fully explain the present invention to those skilled in the art.

[0013] The embodiment of the present invention proposes a door hinge for a washing machine. The door hinge uses a steel wire to adjust the elastic force of the spring. The action principle of adjusting the door closing speed through the spring is simple, the manufacturing unit price is relatively low, and it can be easily assembled. To this end, the structure of the door hinge using steel wire is carefully studied, and the principle of the door hinge operation through the steel wire is explained in detail. The door hinge of this embodiment connects the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap