Saw dust rod forming machine

A technology of forming machine and sawdust, which is applied in the direction of wood processing equipment, recycling technology, biofuel, etc., to achieve the effects of excellent workability, lower manufacturing unit price, and cost restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the wood chip stick molding machine which concerns on this invention is demonstrated in detail based on drawing which shows the embodiment.

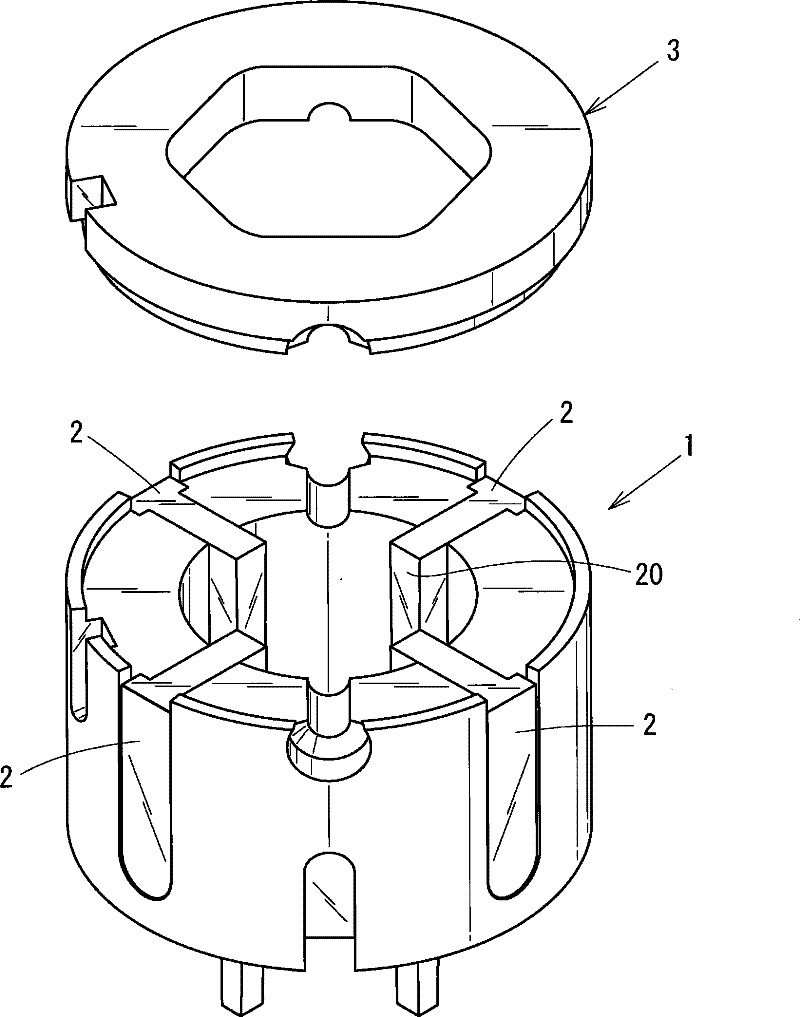

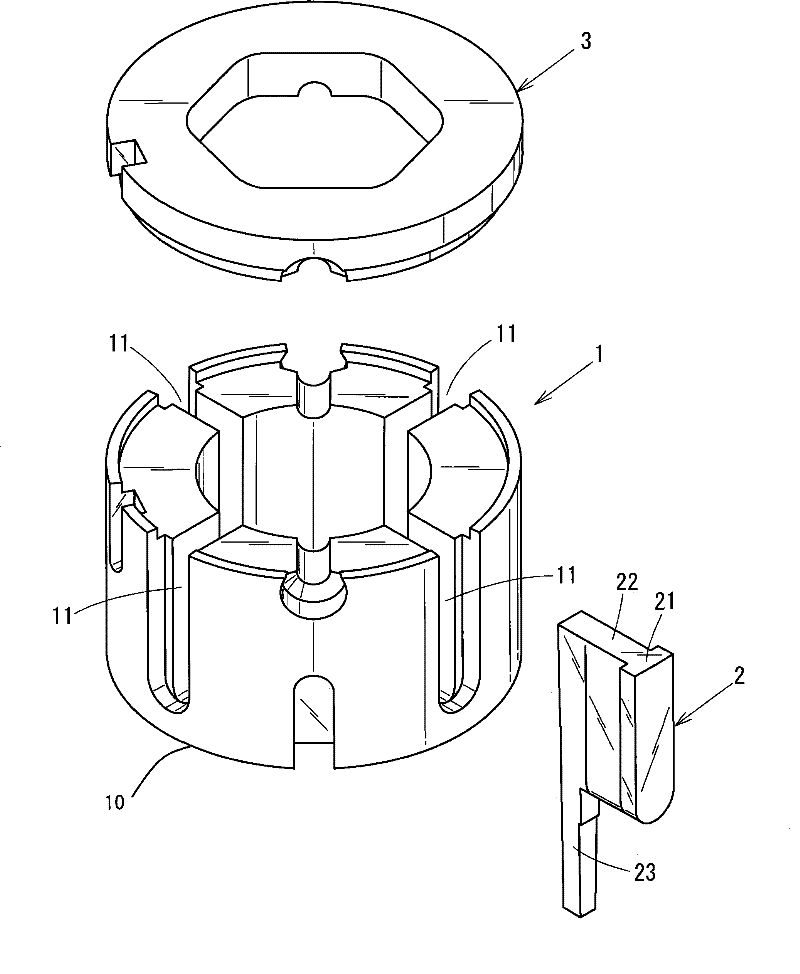

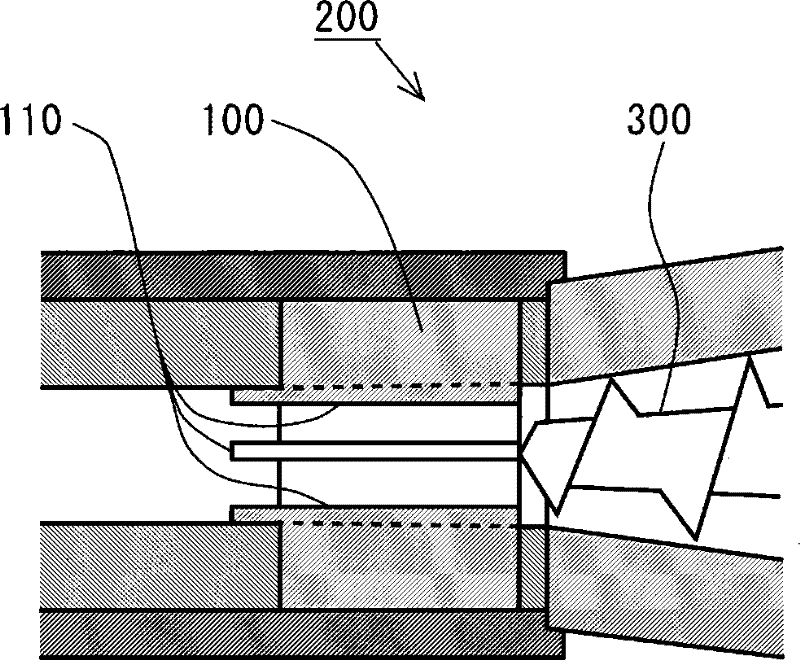

[0034] figure 1 It is a perspective view of a former used in the sawdust rod forming machine according to the present invention. The shaper 1, is in image 3 In the wood chip stick forming machine 200 of the conventional example shown, instead of Figure 4 The former 100 shown in the prior art is mounted on image 3 A former used in the sawdust stick forming machine 200 of the conventional example shown. In addition to the shaper 100, the sawdust stick forming machine related to the present invention is the same as image 3 The structures shown are the same, so the accompanying drawings are omitted. figure 2 It is an exploded perspective view of the above-mentioned former 1 .

[0035] Such as figure 1 As shown, 1 is a shaper into which four tooth-shaped groove forming parts 2 are inserted. Four groove formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com