Mover for linear motor and manufacturing method thereof, linear motor comprising motor

The technology of a linear motor and manufacturing method is applied in the direction of electric components, motor generators, electrical components, etc., which can solve the problems of complex manufacturing process, enlarged size, and increased size and weight of the mover 12, so as to reduce the manufacturing unit price, The effect of improving manufacturing yield and reducing overall size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, preferred embodiments of the mover for a linear motor according to the present invention will be described in detail with reference to the drawings.

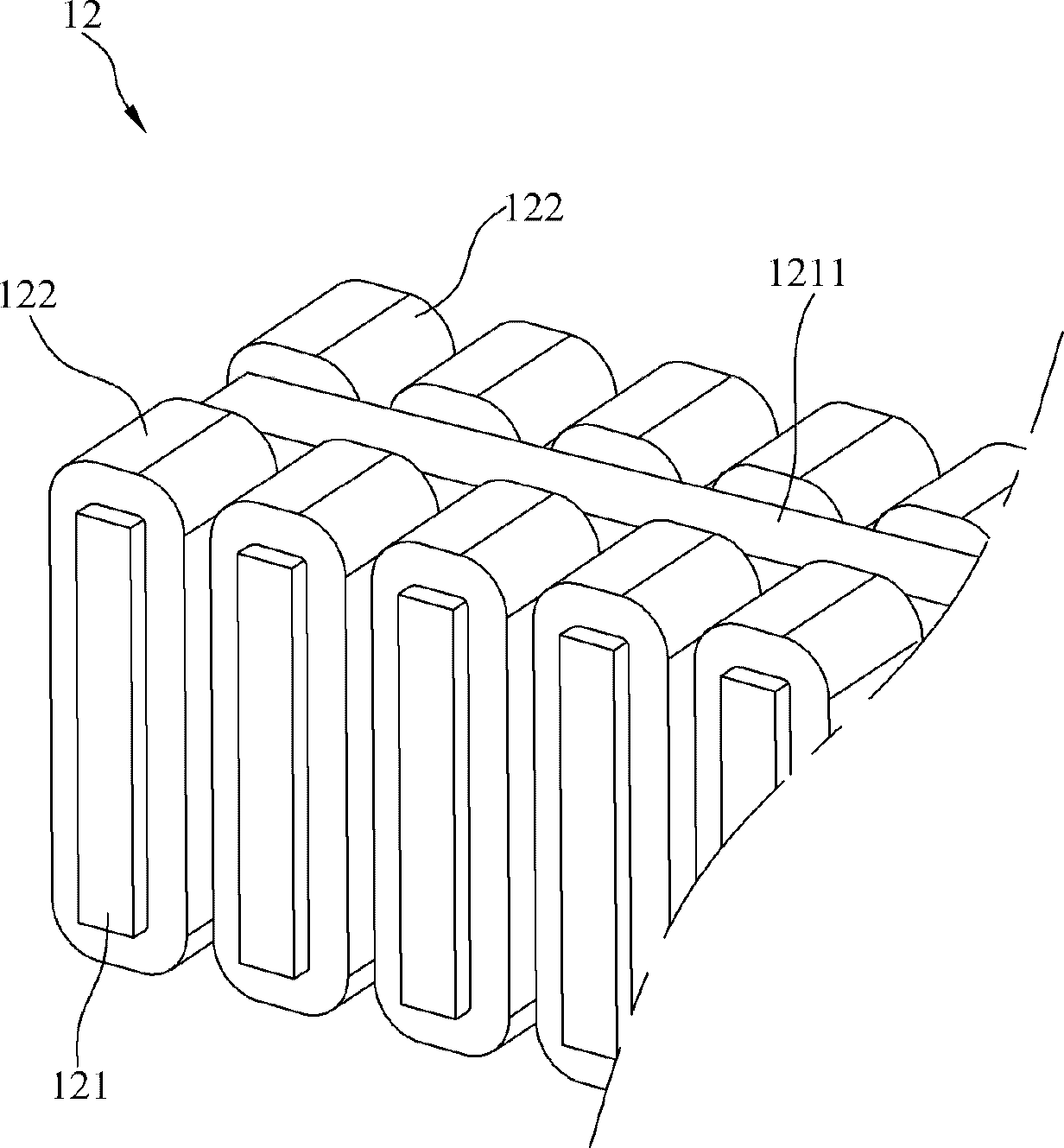

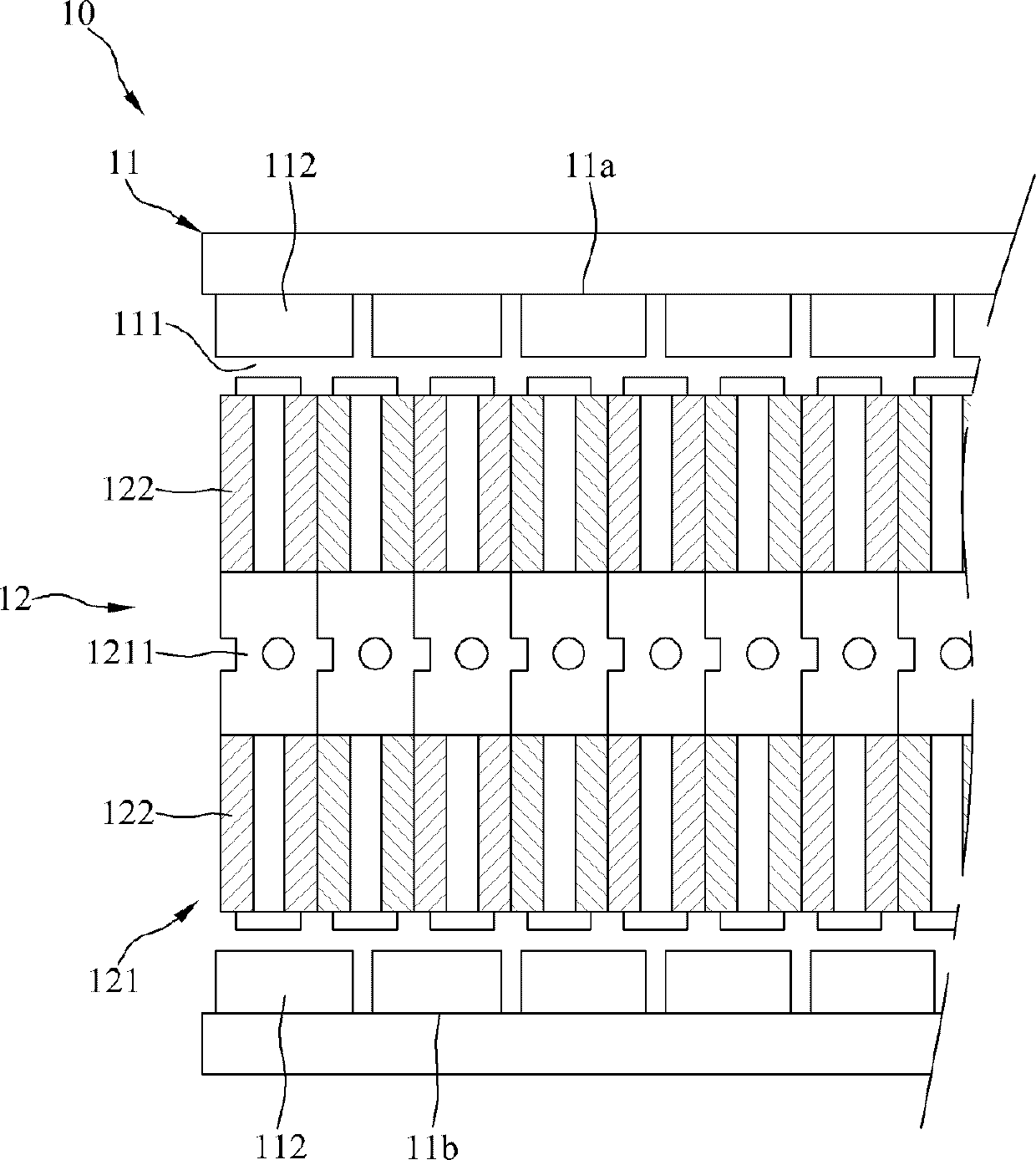

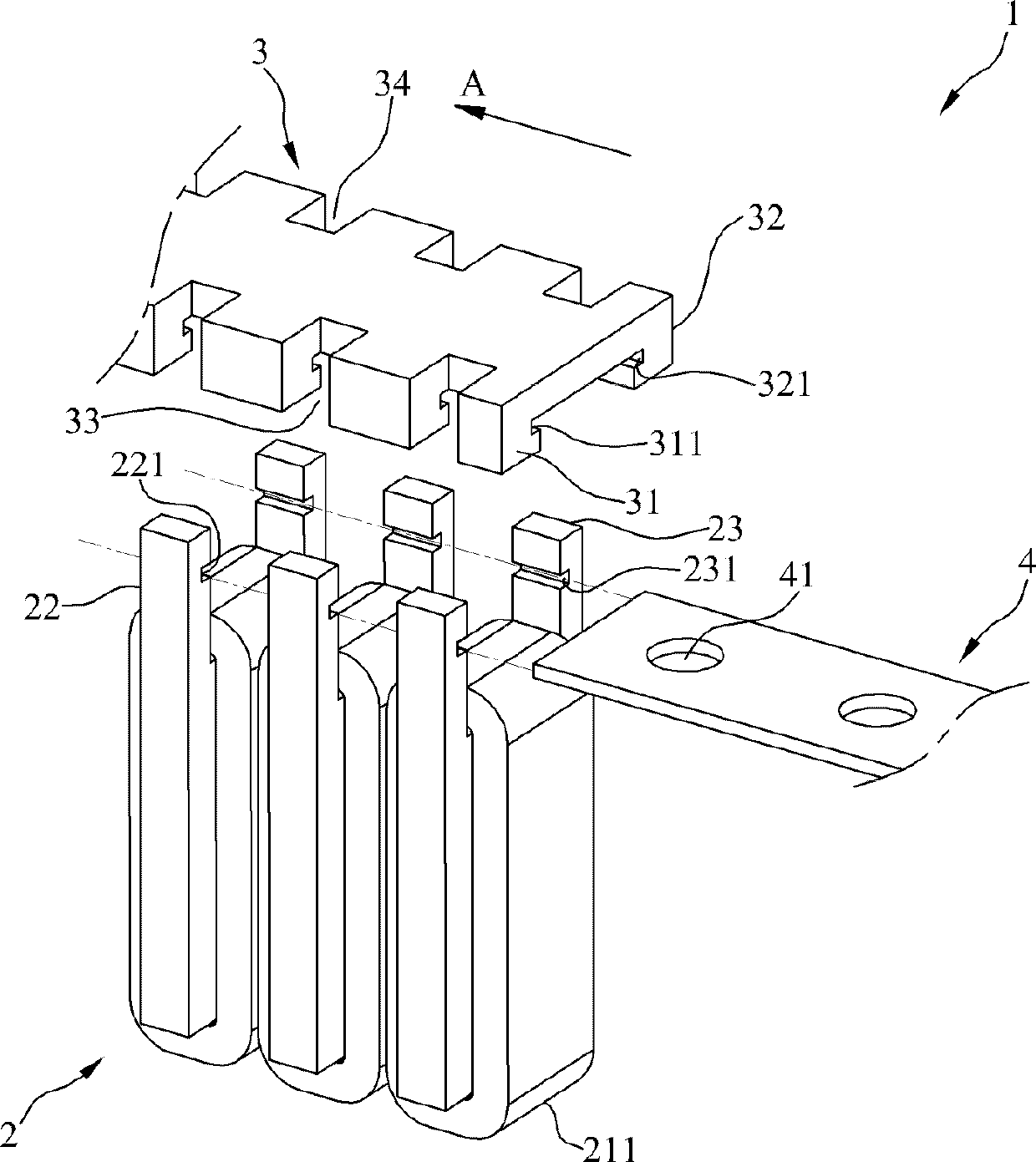

[0028] image 3 It is an exploded perspective view schematically showing a mover for a linear motor according to the present invention; Figure 4 It is a perspective view schematically showing the assembled state of the mover for a linear motor according to the present invention; Figure 5 is a perspective view schematically showing a coil component according to the present invention; Figure 6 It is a conceptual diagram schematically showing a combination relationship of movers for linear motors according to the present invention; Figure 7 It is a side view showing the coupled state of the mover for a linear motor according to the present invention.

[0029] refer to image 3 , The mover 1 for a linear motor according to the present invention includes a coil component 2 , a connection component 3 and a couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com