Substrate carrying device and substrate carrying method utilizing the same

A technology for substrate handling and substrate support, which is applied in the directions of transportation and packaging, program control manipulators, lighting and heating equipment, etc., can solve the problems of increasing the time for handling substrates 100, reducing the productivity and qualification rate of electronic components, and improving productivity and qualification. efficiency, increase speed, and reduce process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the substrate transfer device according to the present invention will be described in detail below with reference to the drawings.

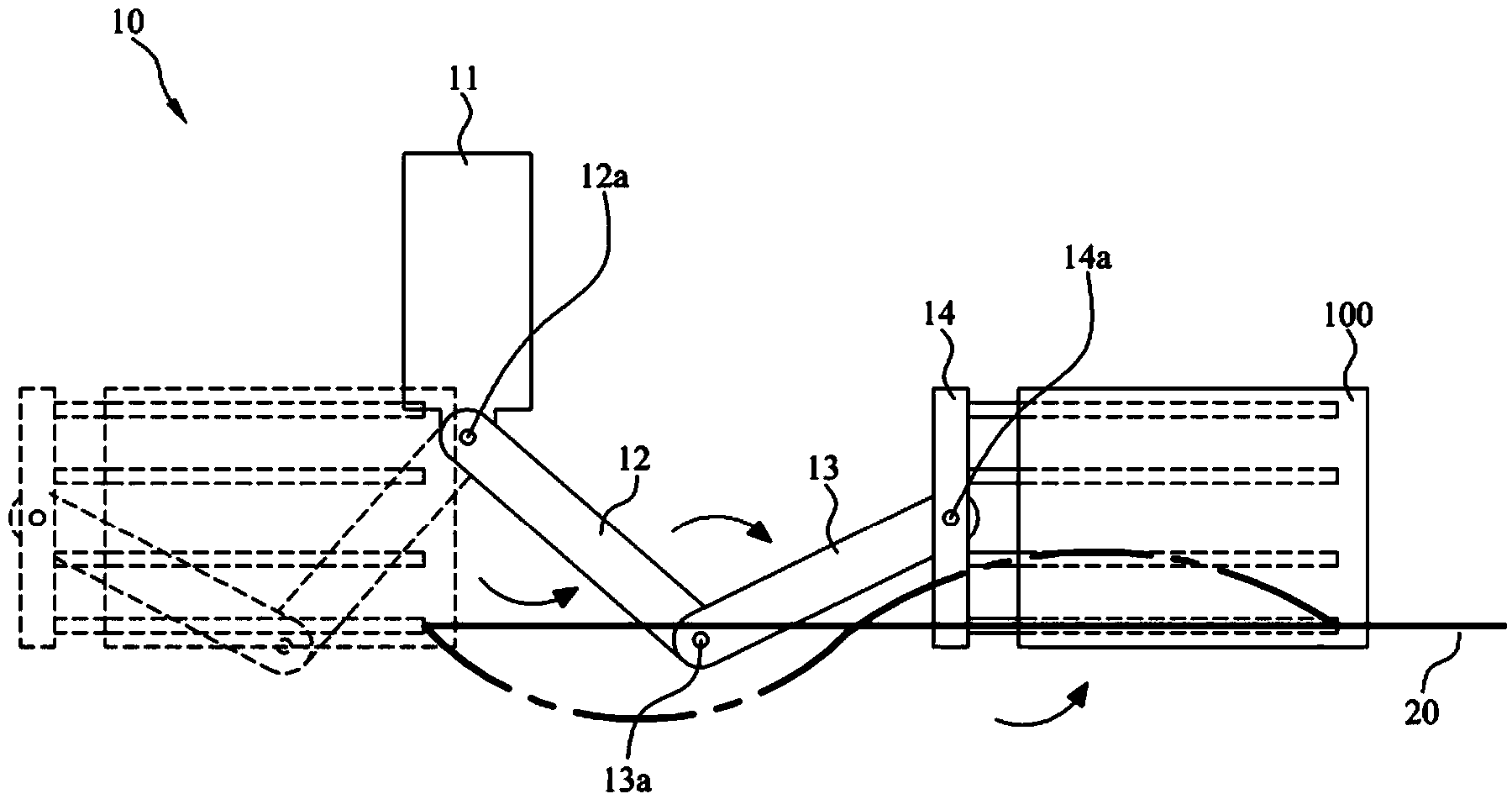

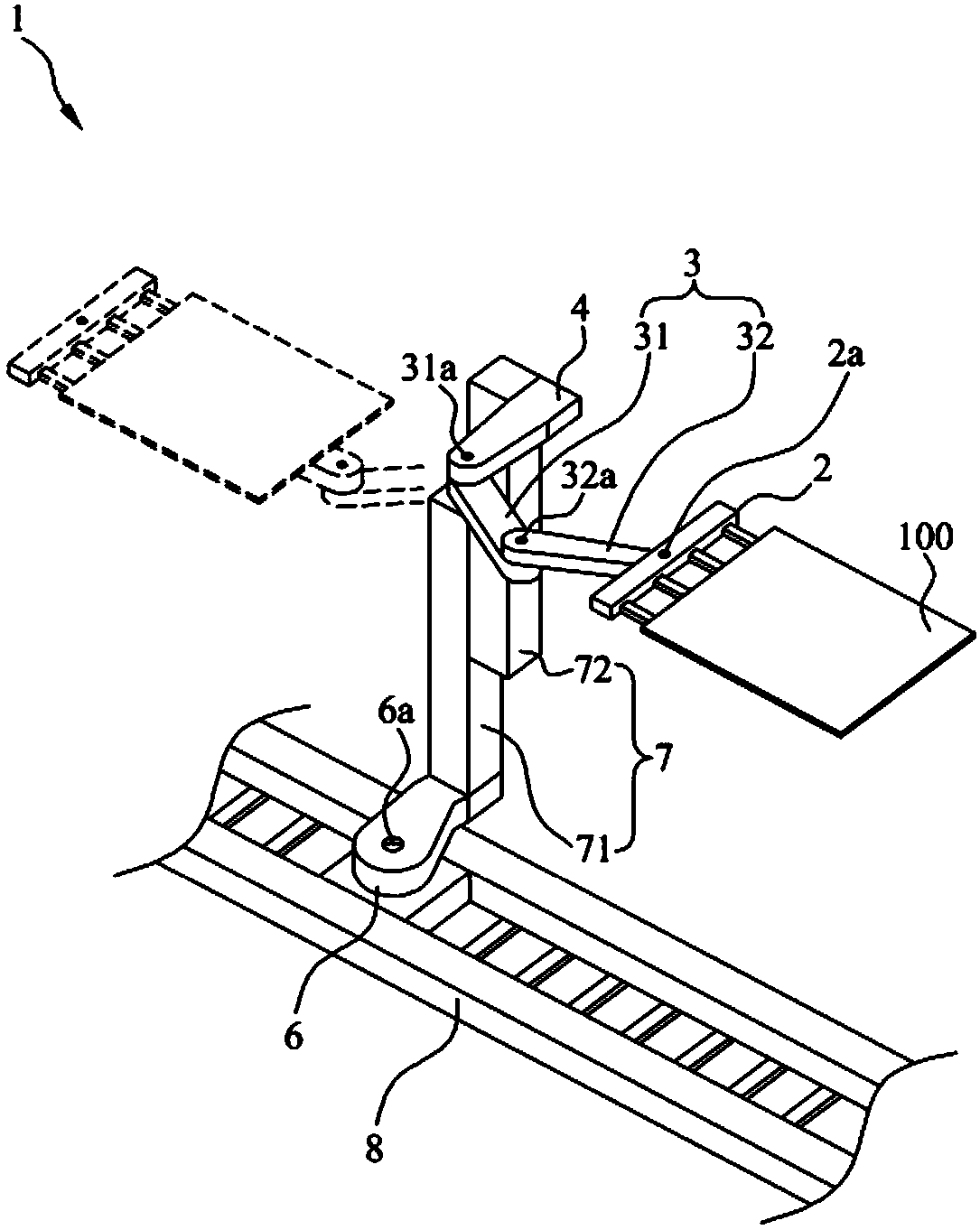

[0045] refer to Figure 2 to Figure 5 , the substrate transfer device 1 according to the present invention is used to transfer a substrate 100 . The substrate 100 is used to manufacture electronic components such as display devices, solar cells, and semiconductor elements. For example, the substrate transfer device 1 according to the present invention can transfer the substrate 100 between chambers in which manufacturing processes such as a deposition device and an etching device are performed on the substrate 100 .

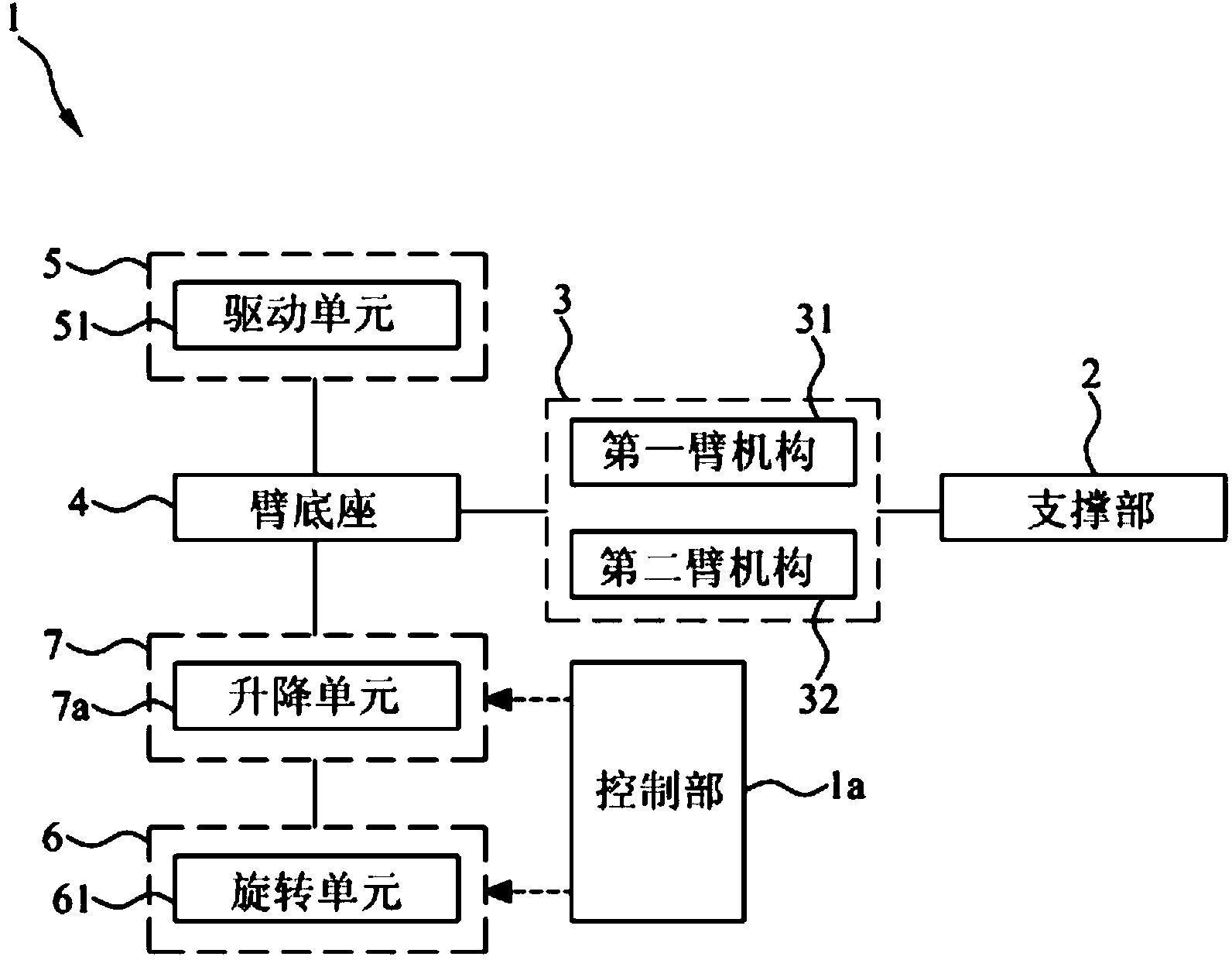

[0046] The substrate transfer device 1 according to the present invention includes: a support part 2 for supporting the substrate 100; an arm unit 3 for rotatably combining the support part 2; an arm base 4 for rotatably connecting the arm unit 3 Combination; drive part 5, in order to move the support part 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com