Ink composition and interior decorative film using same

A technology for ink composition and interior decoration, applied in the directions of ink, decoration, application, etc., can solve the problems of complicated manufacturing process, low economy and productivity, etc., to save the manufacturing unit price, improve the adhesion between layers, and improve the appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

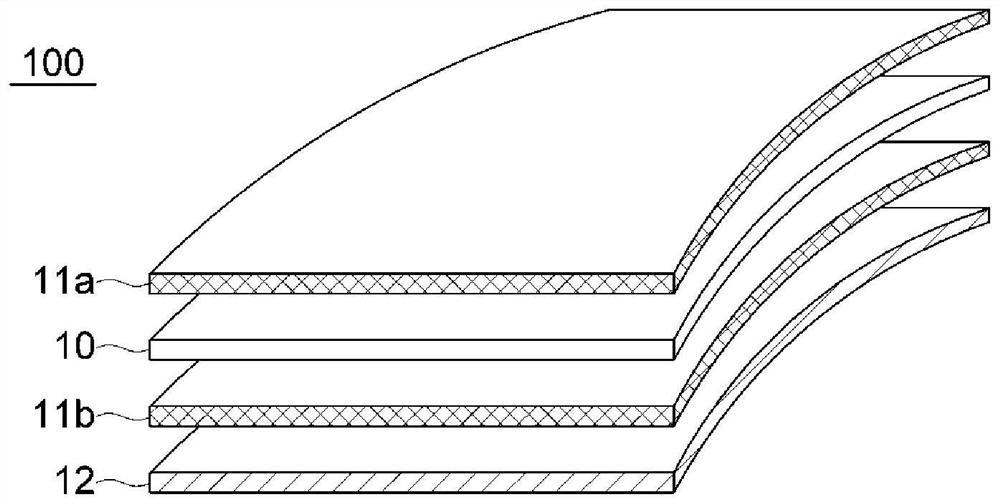

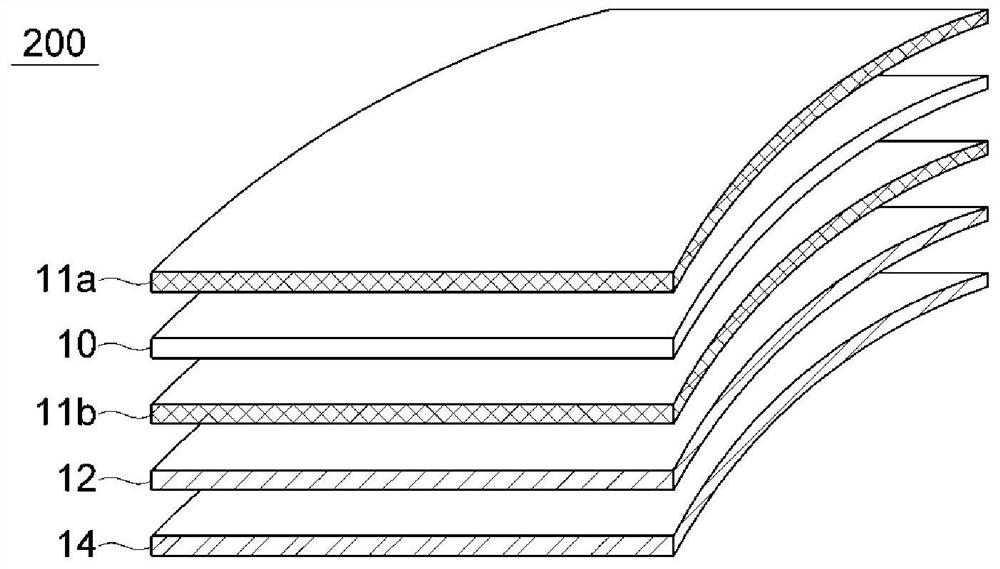

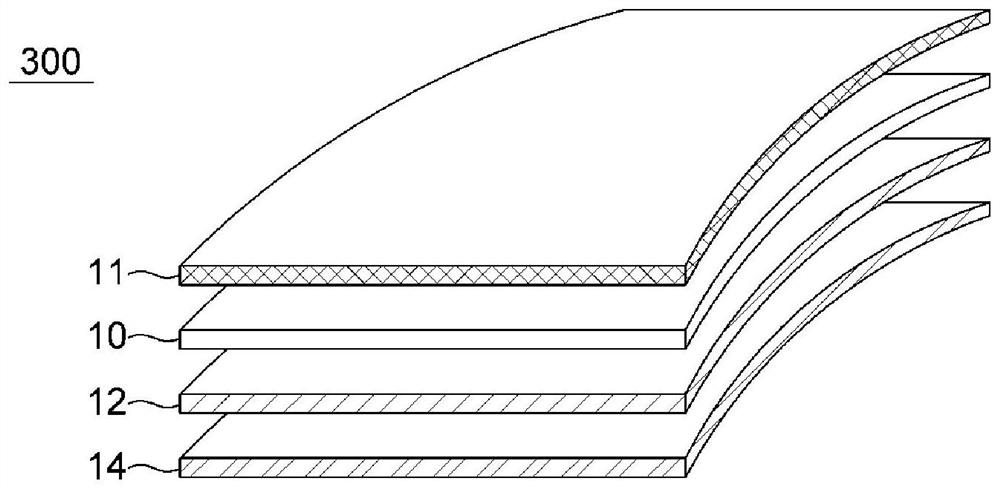

Image

Examples

Embodiment 1

[0107] [Example 1. Preparation of ink composition for printing]

[0108] The components and compositions of the raw materials constituting the printing ink composition of the present invention are shown in Table 1 below. According to the composition recorded in the following table 1, after preparing the medium (first solution) for aluminum (Al) slurry, aluminum (Al) slurry (second solution) and solvent respectively, they are mixed according to the weight ratio of 100:15:50 Mixing and stirring prepared the printing ink composition of Example 1.

[0109] 【Table 1】

[0110]

[0111] 1) Cellulose acetate butyrate: number average molecular weight 16,000, Tg 85°C, melting temperature 135°C

[0112] 2) Aluminum (Al) powder: plate shape, average size 12μm, thickness 40nm

Embodiment 2

[0113] [Example 2. Production of an interior film with a metal print layer]

[0114] On one side of a transparent polyethylene terephthalate (PET) film with a thickness of 30 μm, apply an ultraviolet curable urethane acrylate resin composition to a thickness of 10 μm to form a coating film, and implement The embossing layer is formed by the embossing process. Then, the UV-curable urethane acrylate resin composition was coated on the other surface of the transparent PET film to form a coating film, and an embossing process was performed to manufacture a semi-finished product in which the embossed layers on both sides were formed. The manufacturing process of the double-sided imprinting implemented above is as follows Figure 7 shown.

[0115] On the semi-finished product formed with the embossed layer on both sides, use such as Figure 8 In the gravure printing machine shown, the printing ink composition of Example 1, the coloring composition comprising polyester, vinyl chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com