Hydraulic dynamic balancing method and system for vibrating gravel

A technology of vibrating crushed stone piles and water pressure, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as loss, construction failure of vibrating crushed stone piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

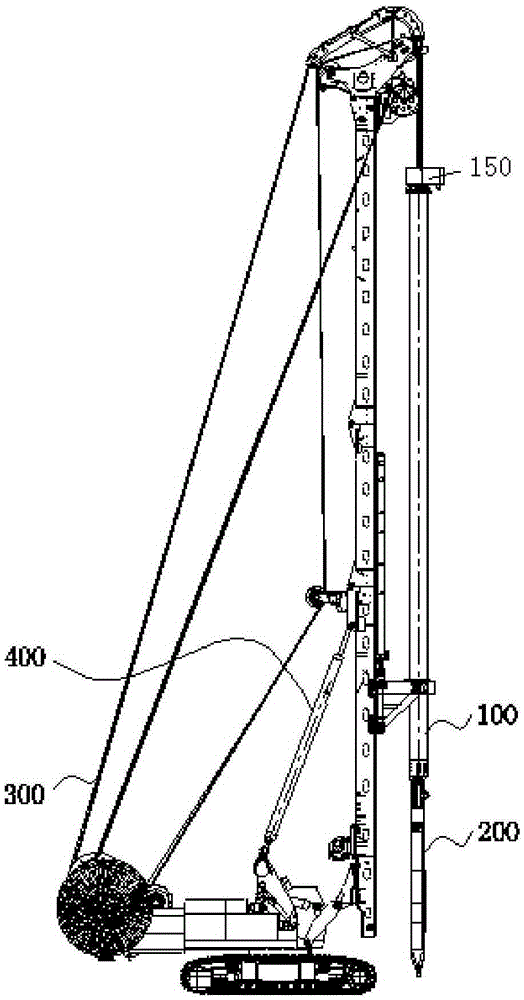

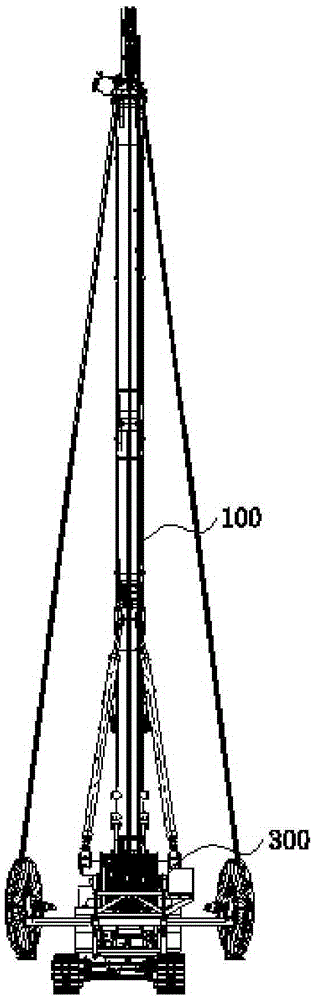

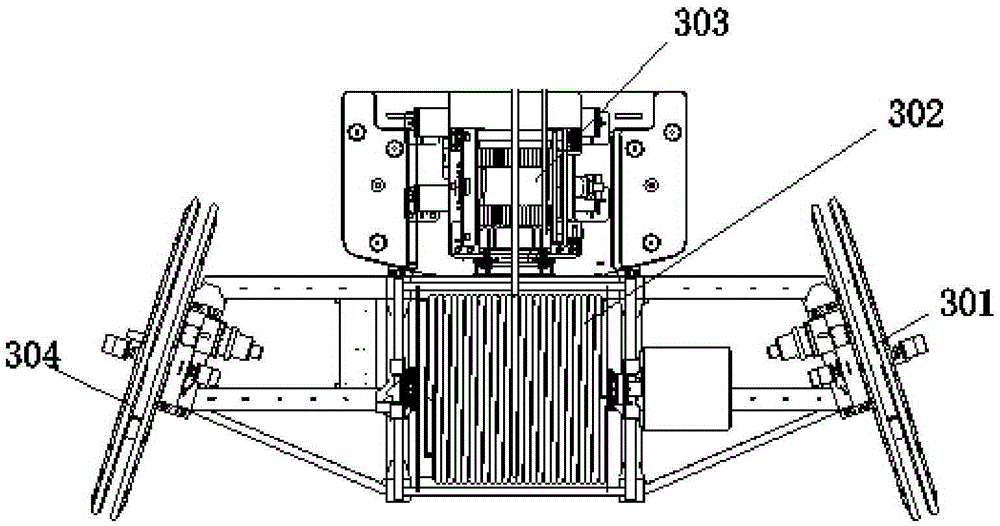

[0044] Such as figure 1 , figure 2 As shown, it is a schematic structural diagram of the vibro-crushing pile machine provided by the present invention. It can be seen from the figure that the vibro-crushing pile machine includes: a crane system 400, an automatic feeding system 300, a drill pipe system 100 and a vibro-concentrator system 200 , the cable hoisting device 302, the water pipe hoisting device 304, the gas pipe hoisting device 301 and the wire rope hoisting device 303 of the automatic feed system are synchronously fed, wherein the axial length of the guide rod 101 in the drill pipe system is adjustable, In order to change the lowering position of the vibrator system relative to the ground; wherein, the automatic feeding system is installed at the rear of the crane in the crane system 400, and is used as a counterweight of the crane.

[0045] Specifically, such as Figure 1-Figure 3As shown, the cable hoisting device 302, the water pipe hoisting device 301 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com