Novel steel plate warehouse

A warehouse and steel plate technology, which is applied in the field of material storage devices, can solve the problems of uneven unloading, sinking of the warehouse body, slow discharging, etc., and achieve the effects of short discharging stroke, flexible collecting location and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

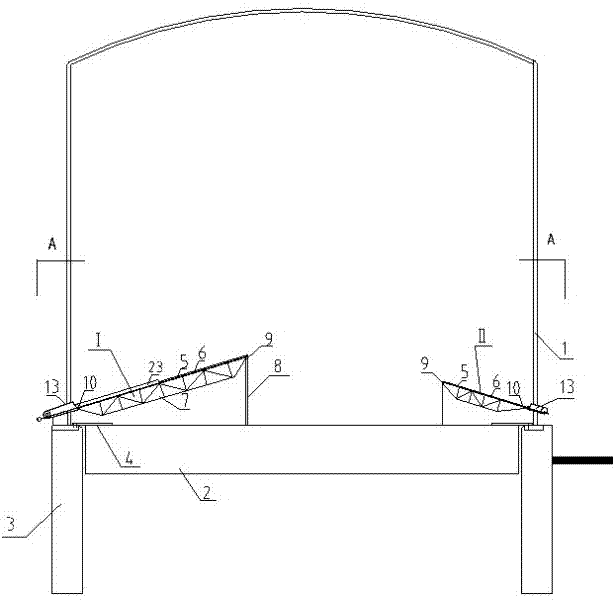

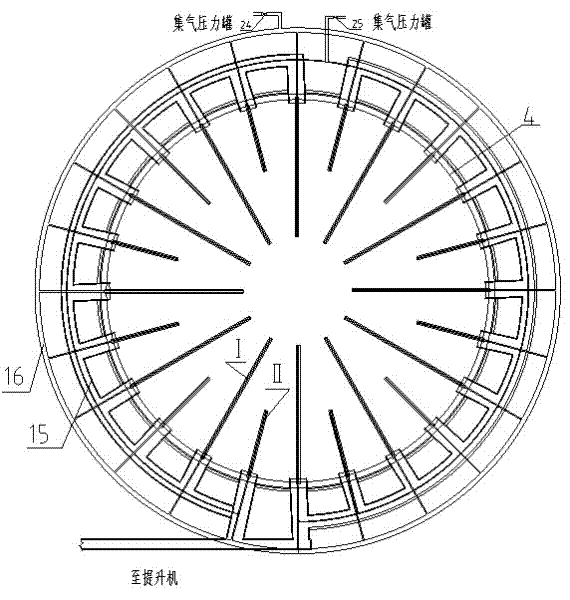

[0015] The specific embodiment of the present invention will be described with reference to the accompanying drawings. The warehouse body 1 of this warehouse is fixedly connected to the concrete ring base 3. There is a gap 17 between the concrete bottom plate 2 and the concrete ring base 3. The width of the gap 17 is 40-80mm. In practical applications, the specific size is determined according to the geological conditions, and the rubber seal The plate 4 is placed on the gap 17, and the annular rubber sealing plate 4 is fixedly connected to the concrete ring base 3 with sinking nails 11. The concrete ring base 3 and the concrete bottom plate 2 are made of reinforced concrete, and the bottom surface of the concrete bottom plate 2 is a hyperboloid bottom surface.

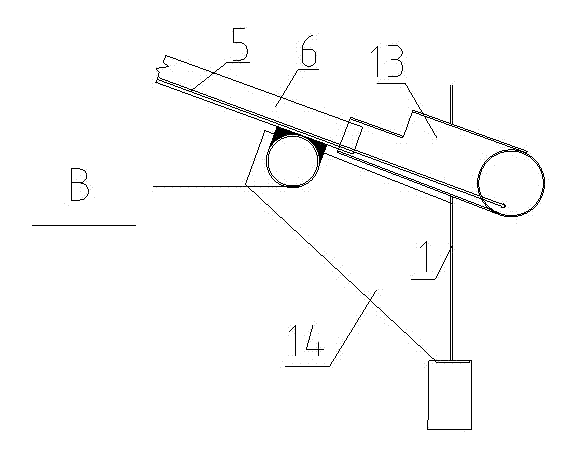

[0016] In the lower part of the warehouse body 1, 24 sets of discharge pipes are uniformly installed, including 12 discharge pipes in the outer area II, 12 discharge pipes in the inner area I, and the discharge pipe I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com