Foundation raft formwork reinforcing device

A formwork reinforcement and foundation raft technology, which is applied in the direction of basic structure engineering and construction, can solve the problems of wasting steel bars, complicated construction, uneconomical, etc., and achieve the effects of improving construction efficiency, convenient operation, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

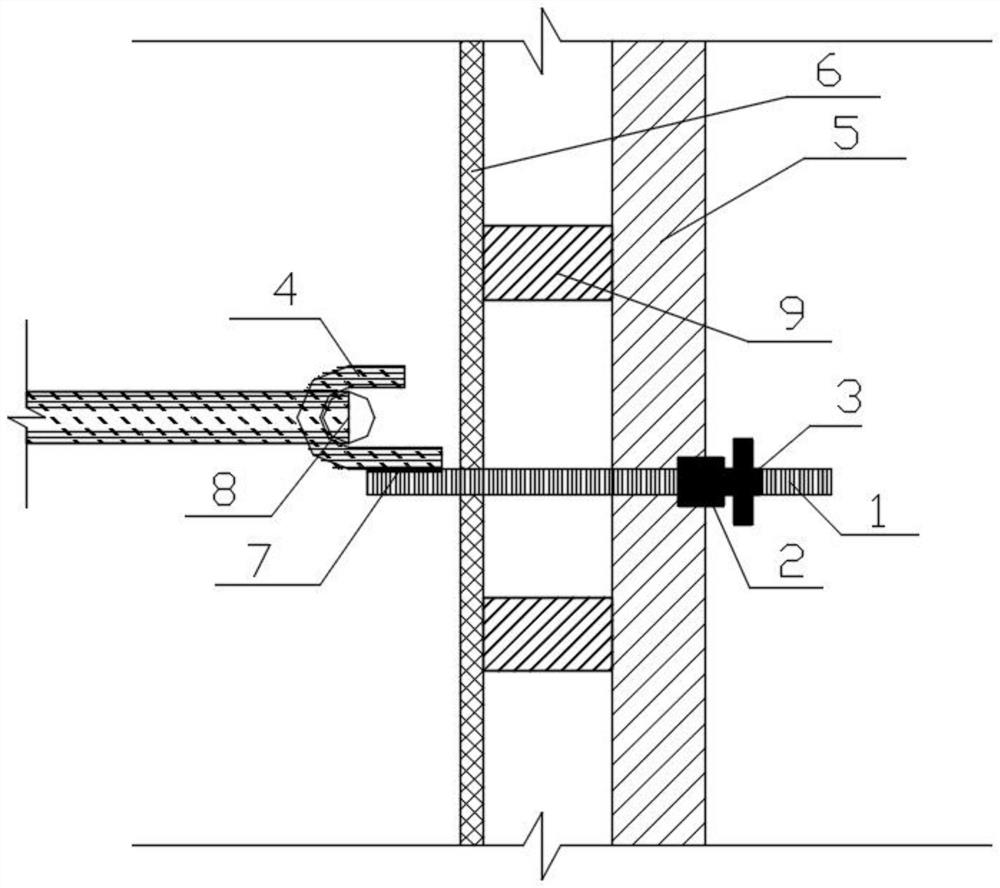

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0019] refer to figure 1 As shown, a basic raft formwork reinforcement device includes: steel pipe main keel 5, the steel pipe main keel 5 is made of aluminum alloy, has good mechanical stability and light weight, the left side of the steel pipe main keel 5 A wooden sub-keel 9 is provided, and the wooden sub-keel 9 is made of a wooden material with stable insulation and improved safety. The multi-layer board 6 is fixedly installed through the wooden sub-keel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com