Sand and lime tiling device for laying floor tiles

The technology of paving tiles and sand ash is applied in the field of construction engineering installation equipment, which can solve the problems of affecting the overall flatness of paving tiles, increasing the difficulty of leveling, poor adhesion, etc., and achieving simple structure, good flatness, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

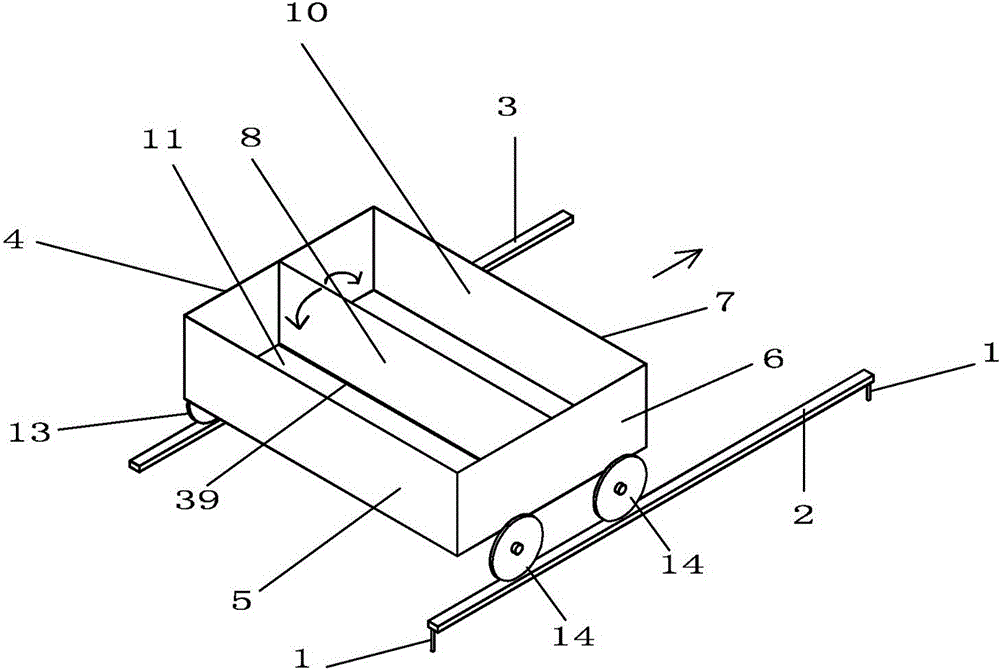

[0030] Such as figure 1 As shown, the sand and ash tiling device for laying floor tiles includes two parts: a base and a guide rail supporting the base; the guide rail includes a horizontal parallel guide groove a2 and a guide groove b3, and the guide groove a2 is supported by a height adjuster 1; the base is supported by a side plate a4 , side plate b5, side plate c6, and side plate d7 form a box shape, and the inside of the box body is divided into a coarse material box 10 at the front end and a fine material box 12 at the rear end by a vertical partition a8. Two pulleys a13 are arranged on the outer surface, and two pulleys b14 are arranged on the outer surface of the side plate c6. The pulley a13 slides on the guide groove b3, and the pulley b14 slides on the guide groove a2. The vertical dividing plate a8 can rotate along the axis a39, the vertical dividing plate a8 falls to the side plate b5, the coarse material box 10 is funnel-shaped, the vertical dividing plate a8 fal...

Embodiment 2

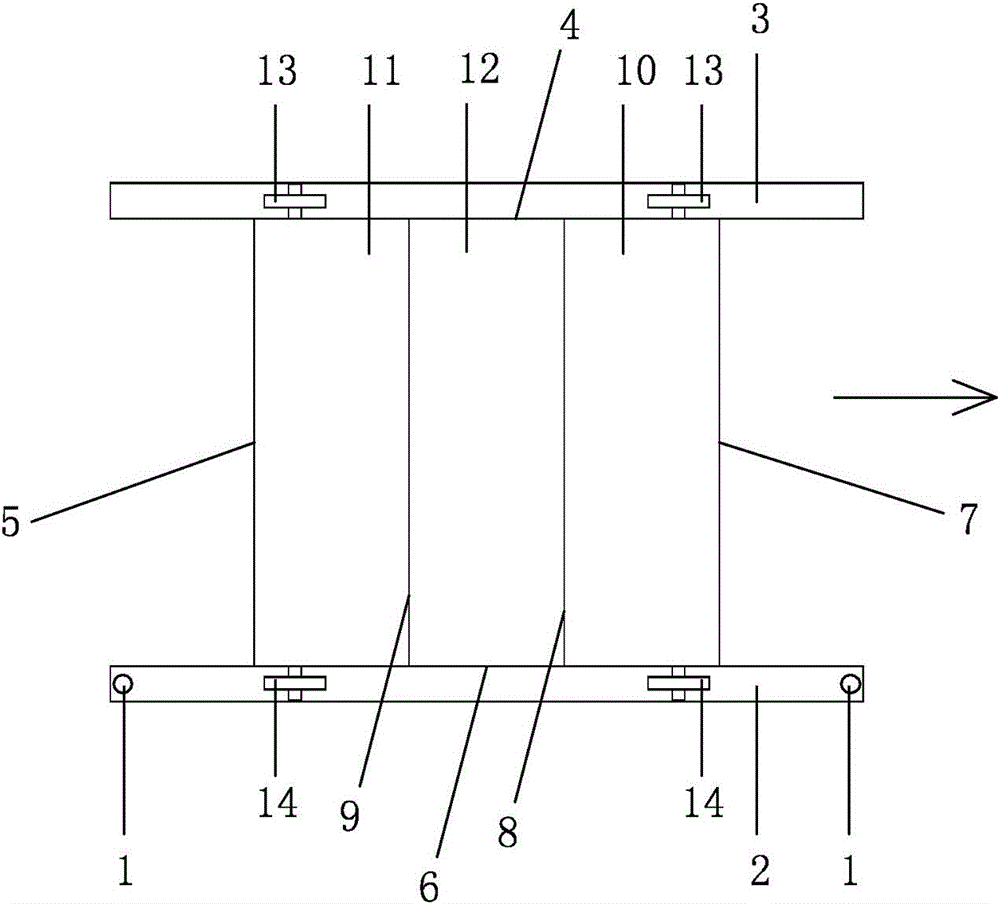

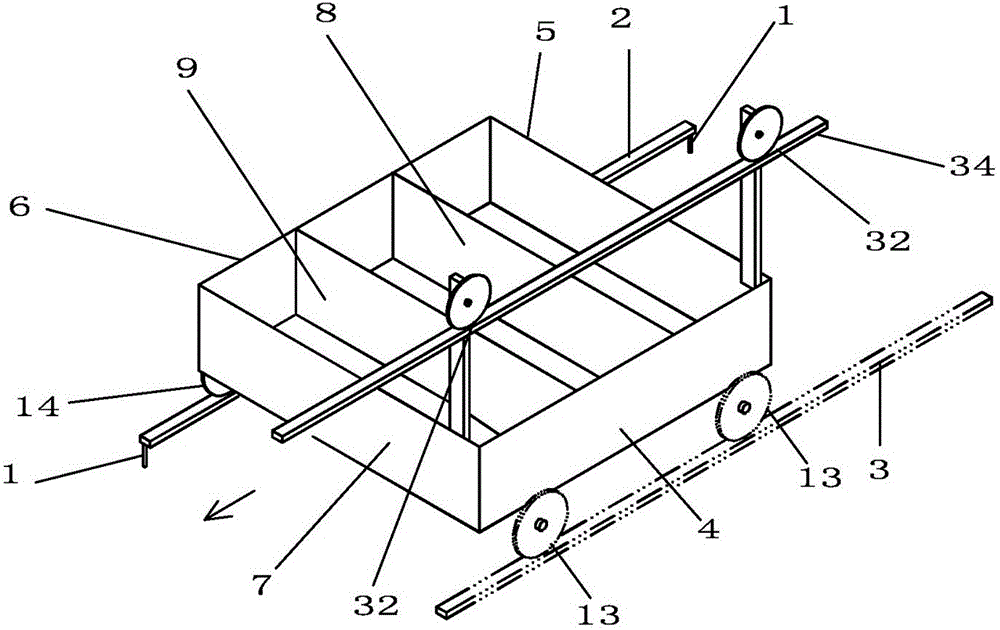

[0033] Such as figure 2 , image 3As shown, the sand and ash tiling device for laying floor tiles includes two parts: a base and a guide rail supporting the base; the guide rail includes a horizontal parallel guide groove a2 and a guide groove b3, and the guide groove a2 is supported by a height adjuster 1; the base is supported by a side plate a4 , side plate b5, side plate c6, and side plate d7 form a box shape, and the inside of the box body is divided into a coarse material box 10 at the front end, a surplus material box 11 at the rear end, and a The fine material box 12 between the coarse material box and the surplus material box. Two pulleys a13 are arranged on the outer surface of the side plate a4, and two pulleys b14 are arranged on the outer surface of the side plate c6. The pulley a13 slides on the guide groove b3, and the pulley b14 slides on the guide groove a2.

[0034] When using the device, the dry material first falls to the ground and is smoothed by the pa...

Embodiment 3

[0036] Such as figure 2 , image 3 As shown, the sand and ash tiling device for laying floor tiles includes two parts: a base and a guide rail supporting the base; the guide rail includes a horizontal parallel guide groove a2 and a guide groove b3, and the guide groove a2 is supported by a height adjuster 1; the base is supported by a side plate a4 , side plate b5, side plate c6, and side plate d7 form a box shape, and the inside of the box body is divided into a coarse material box 10 at the front end, a surplus material box 11 at the rear end, and a The fine material box 12 between the coarse material box and the surplus material box. Two pulleys a13 are arranged on the outer surface of the side plate a4, and two pulleys b14 are arranged on the outer surface of the side plate c6. The pulley a13 slides on the guide groove b3, and the pulley b14 slides on the guide groove a2. On the side plate b5 and side plate d7 at one end of the side plate a4, a pulley 32 is used for lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com