Diaphragm stroke test device and test method

An experimental method and an experimental device technology, applied in the field of diaphragm stroke experimental devices, can solve the problems of time-consuming and labor-intensive installation of diaphragms, increased production costs, and delays in the construction period, and achieve the effects of simple operation methods, reduced experimental cycles, and avoided damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

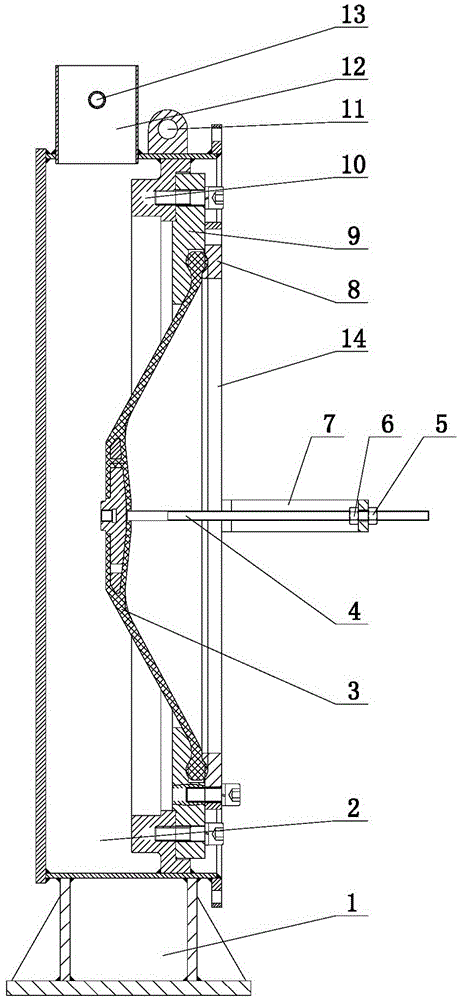

[0035] The diaphragm stroke experiment device of the present invention comprises a cavity 2, and is characterized in that: one side of the cavity 2 is an opening 14, and a support 10 is arranged in the cavity 2 corresponding to the opening 14; a liquid filling port 12 is arranged above the cavity 2 An overflow port 13 is provided on the side of the liquid filling port 12; a support frame 7 is provided outside the opening 14, and a screw rod 4 extending into the opening 14 is provided on the support frame 7, and the screw rod 4 passes through the first positioning in the support frame 7 The nut 6 and the second positioning nut 5 outside the support frame 7 are fixed on the support frame 7 .

[0036] As a preferred solution of the present invention, a base 1 is provided at the bottom of the cavity 2 , and a lifting ear 11 is provided above the cavity 2 .

[0037] As another preferred solution of the present invention, the support 10 is provided with a front pressing plate 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com