bicycle hydraulic brake

A technology of hydraulic brakes and bicycles, applied in bicycle brakes, liquid resistance brakes, bicycle accessories, etc., can solve problems such as uneven wear, achieve reliable and labor-saving braking, and improve sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

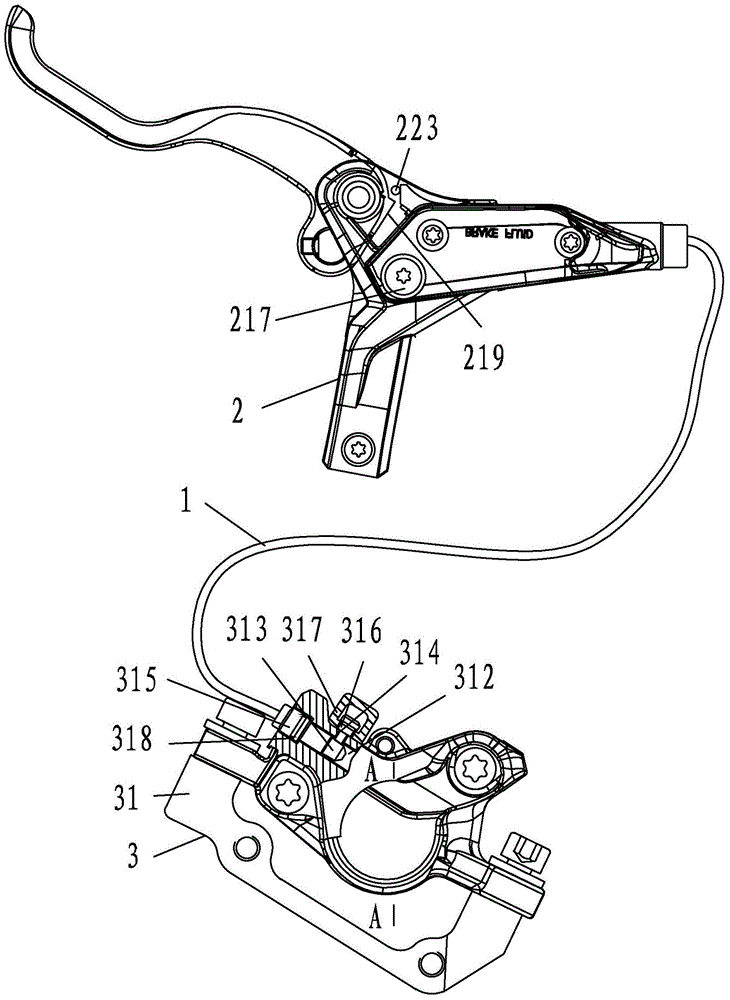

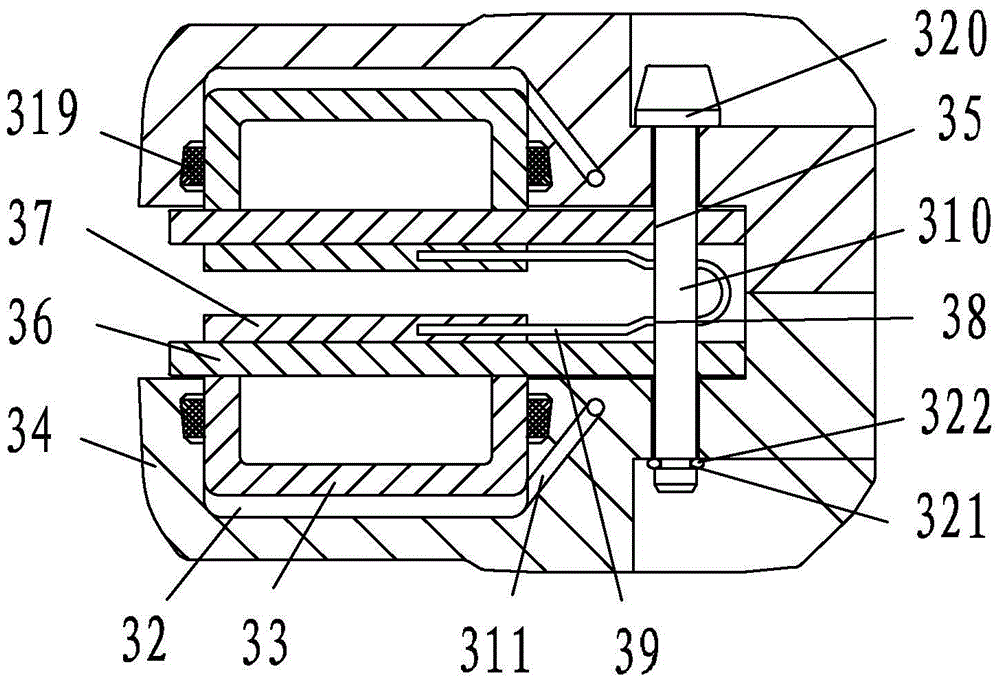

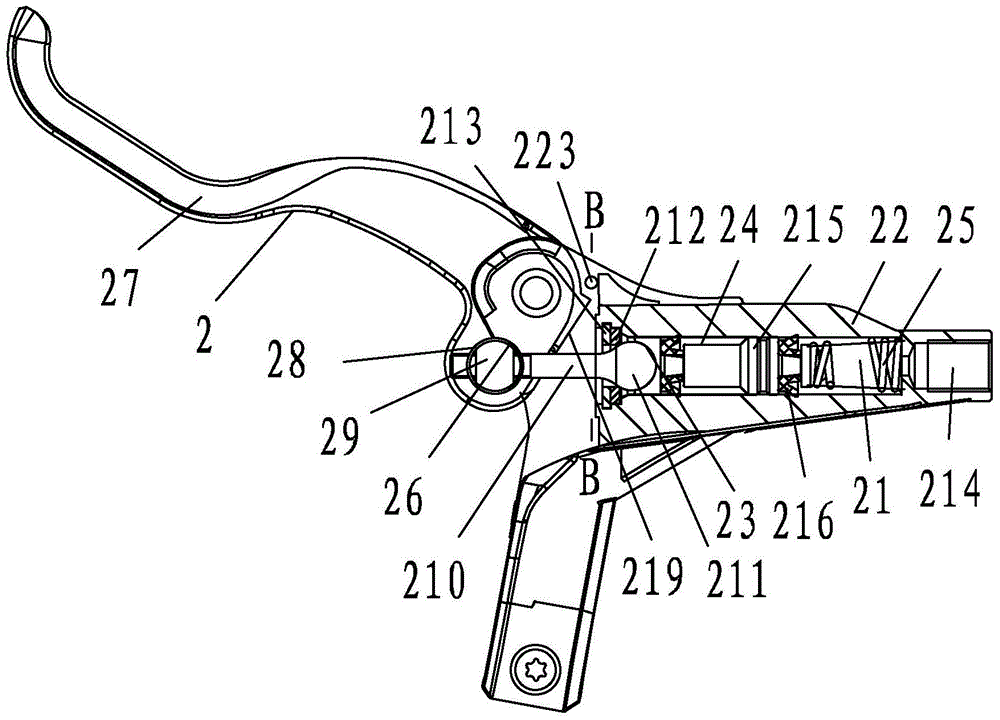

[0020] as attached figure 1 to attach Figure 5 Shown: a bicycle hydraulic brake, including a brake pump assembly 2, a brake caliper assembly 3, and a connecting oil pipe 1; the brake caliper assembly 3 includes a shell 31 connected with a bicycle body screw, two An oil cylinder hole 32 and a brake piston 33 located in the oil cylinder hole 32 and a caliper 34 screwed to the housing 31 are respectively provided on the opposite end faces. Pressing plate 36, two brake pads 37 each bonded with a pressing plate 36 inboards, both sides are respectively provided with a U-shaped reed 39 with a through hole 38 and two ends are respectively inlaid with a braking pad 37 one end connection, two The end is respectively provided with the guide rod 310 of block 320 and draw-in groove 321, and the elastic retaining ring 322 of axle; The ring 322 is fixed in the clamping groove 321...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com