Water cup assembly, cleaning assembly and range hood

A technology for range hoods and water cups, which is applied in the directions of removing oil fume, cleaning methods and utensils, and cleaning methods using liquids, etc. performance and reliability, improve performance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

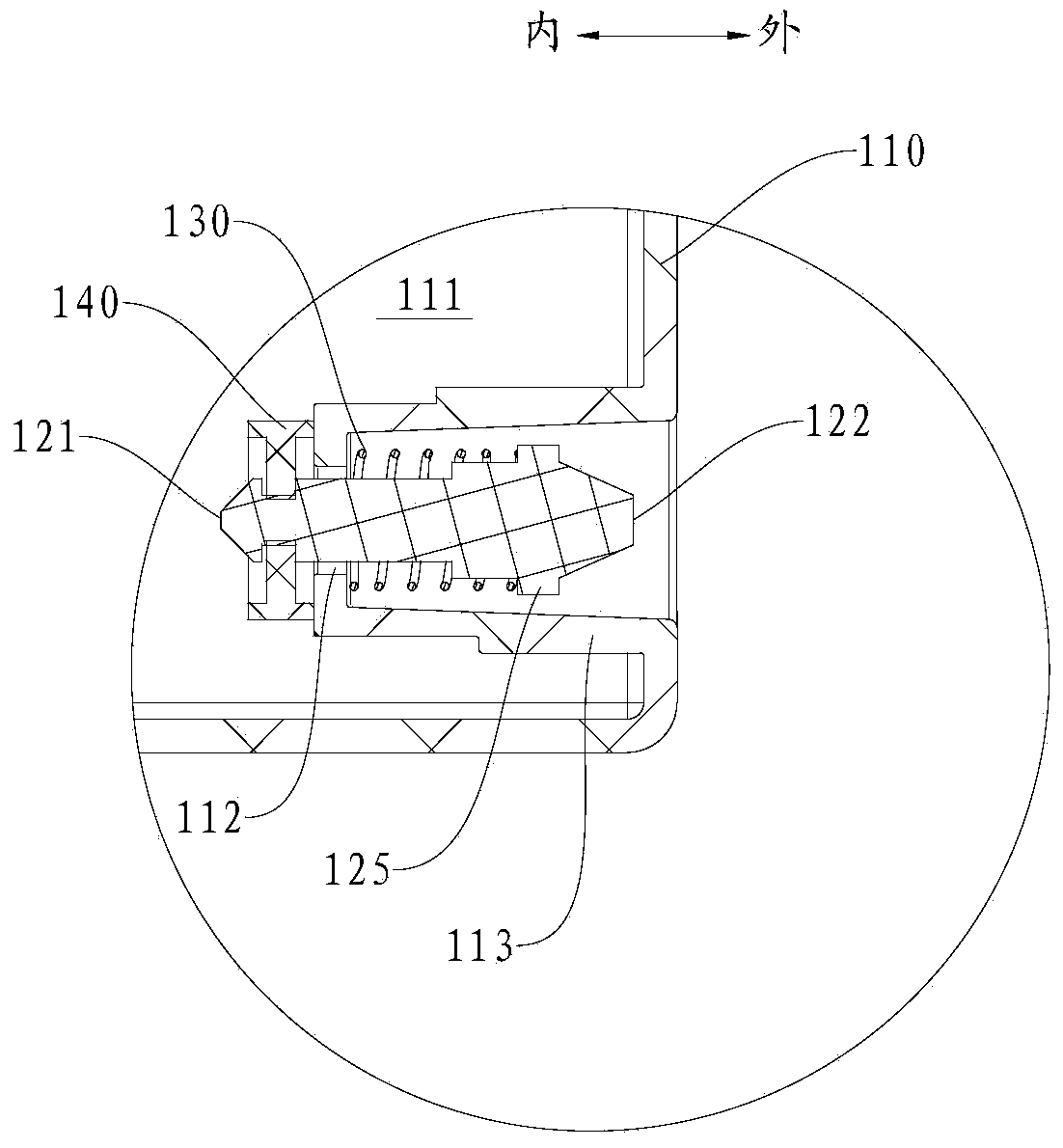

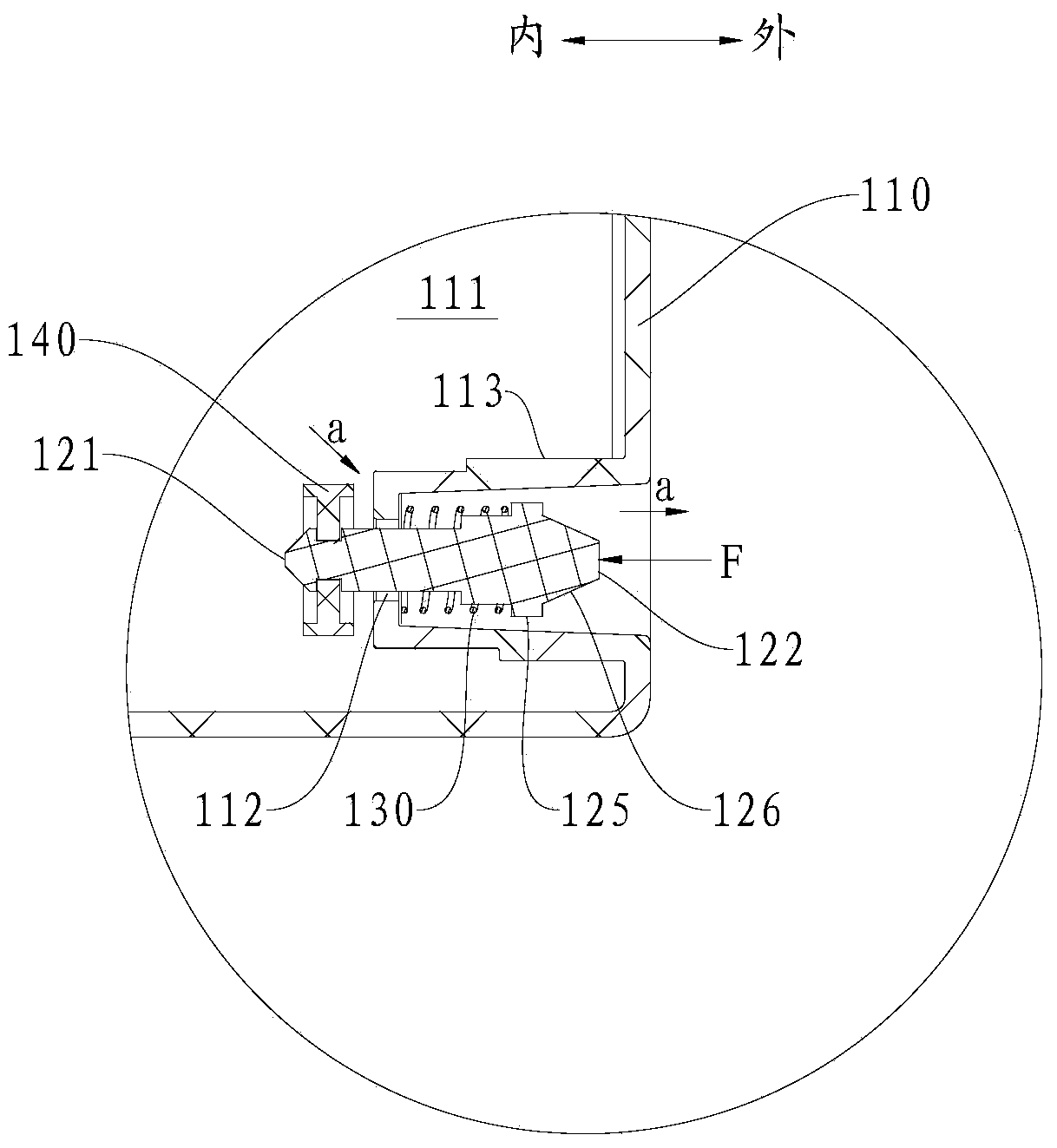

[0040] Refer below Figure 1-Figure 6 A water cup assembly 100 for a range hood according to an embodiment of the present invention will be described in detail.

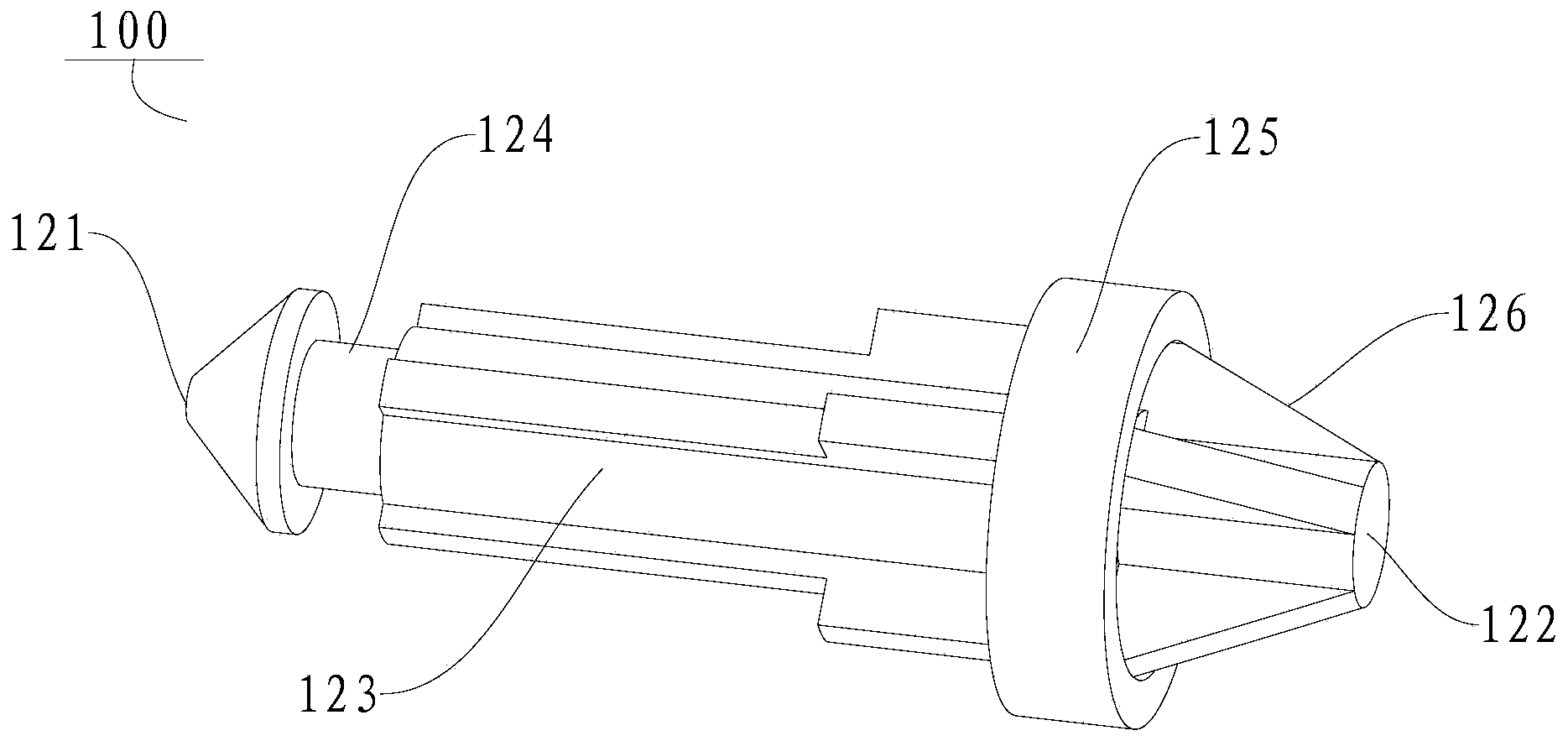

[0041] Such as Figure 1-Figure 6 As shown, a water cup assembly 100 for a range hood according to an embodiment of the present invention includes: a water cup 110 , a push rod 120 , and an elastic member 130 .

[0042] Specifically, the water cup 110 has a chamber 111 for containing cleaning water, and a first communication port 112 is formed on a side wall of the chamber 111 . Here, “a side wall on one side of the chamber 111 ” may refer to the bottom wall of the chamber 111 , or may refer to a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com