A magnetic tweezers and optical tweezers measurement and control system

A technology of measurement and control system and magnetic tweezers, applied in the microscopic field, can solve problems such as unrealizable, non-rotating, easy to burn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

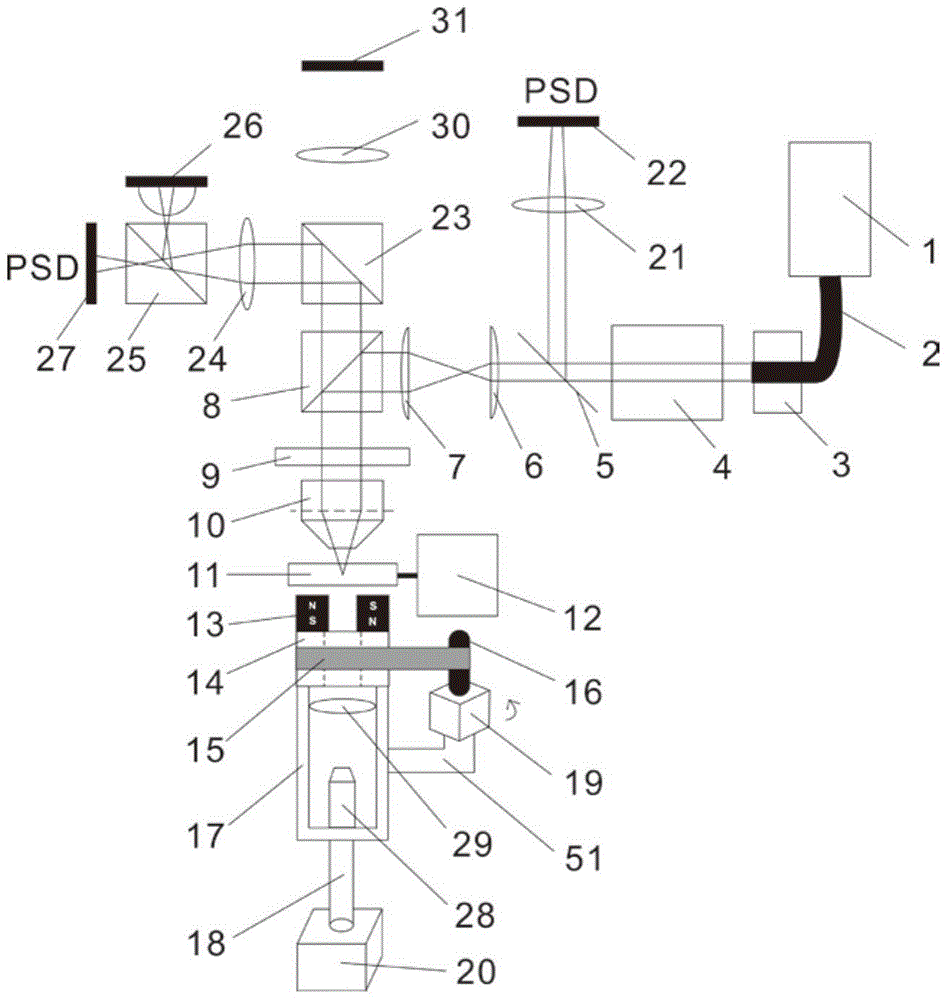

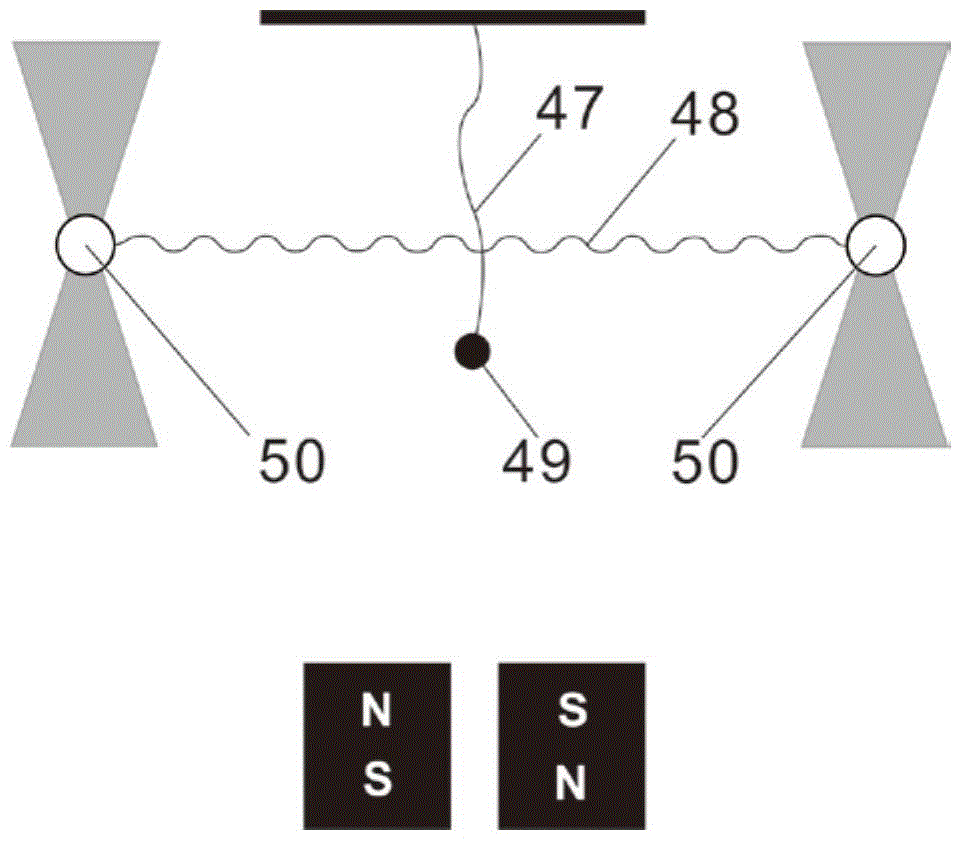

[0021] see figure 1 , a magnetic tweezers and optical tweezers measurement and control system provided in an embodiment of the present invention is used to control the first experimental molecule 47 connected to the surface of the magnetic ball 49 and the second experimental molecule 47 bound to the surface of the microbead 50 in the experimental solution. Molecule 48, the experimental solution includes a solution of microbeads 50, a solution containing the second experimental molecule 48, and an experimental buffer; it is characterized in that the measurement and control system includes:

[0022] The sample pool 11, the first experimental molecule 47 connected to the surface of the magnetic ball 49 and the second experimental molecule 48 bound to the surface of the microbead 50 are arranged in the sample pool 11;

[0023] A sample action device, the sample action device is connected to the sample pool 11, the sample action device drives the sample pool 11 to move, and is used...

Embodiment 2

[0046] In order to introduce the embodiment of the present invention more clearly, the following introduces it from the usage method of the embodiment of the present invention.

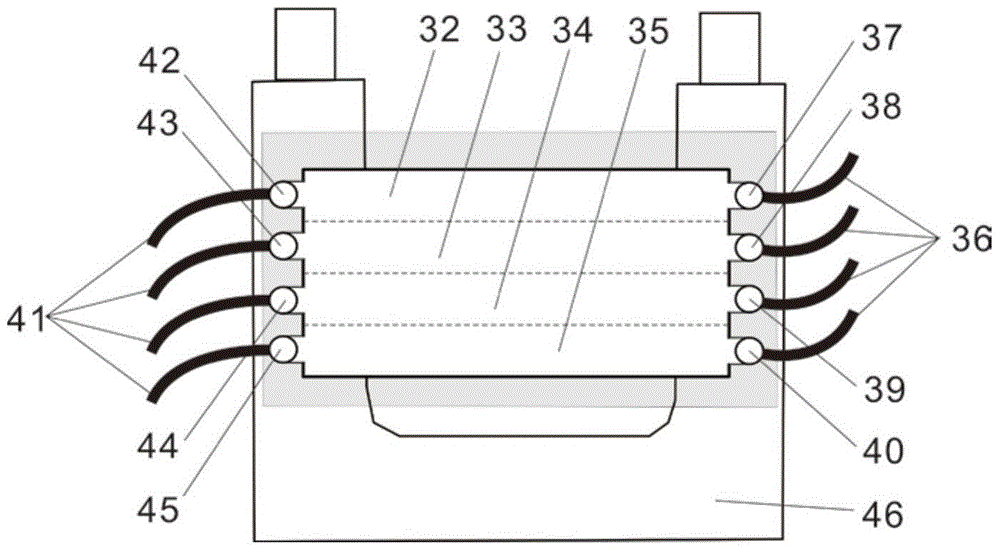

[0047] Firstly, the top of the fourth laminar flow channel 35 is treated, such as making it coated with digoxin antibody molecules. Next, the sample cell 11 is assembled into the system. Open the first liquid inlet 37, the second liquid inlet 38, the third liquid inlet 39 and the fourth liquid inlet 40 and the first liquid outlet 42, the second liquid outlet 43, the third liquid outlet 44 that is The valve of the fourth liquid outlet 45 applies hydraulic pressure to inject the solution containing microbeads 50 , the solution containing the second test molecule 48 , the buffer solution and the solution containing magnetic balls respectively at a slow speed. Wherein, the surface of the microbead and the two ends of the second experimental molecule 48 have been treated so that they can be combined toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com