High-resolution camera lens

A camera lens and high-pixel technology, applied in optical components, optics, instruments, etc., can solve the problem that the incident angle of light on the imaging surface is not effectively controlled, and suppress ghost images, etc., so as to improve the imaging quality and reduce the CRA angle , the effect of large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

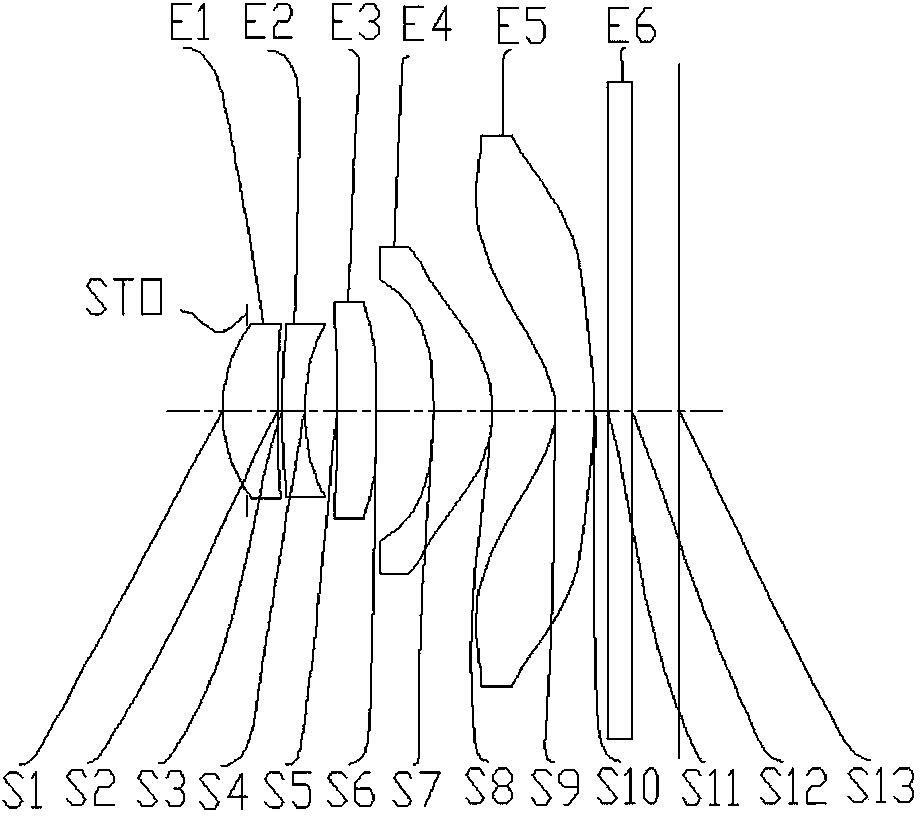

[0084] In Embodiment 1, the lens system satisfies the conditions in the following table:

[0085] Table 1

[0086] surface number

thickness

Material

Effective caliber

Conic coefficient

obj

sphere

infinity

infinity

STO

sphere

infinity

-0.2106

0.7250

S1

Aspherical

1.3135

0.4798

1.54,56.1

0.7622

-0.8579

S2

Aspherical

57.8671

0.0360

0.7542

-150.8162

S3

Aspherical

6.2035

0.2000

1.64,23.8

0.7553

61.7324

S4

Aspherical

1.7651

0.2786

0.7537

2.8130

S5

Aspherical

13.1243

0.3460

1.54,56.1

0.7596

2.1722

S6

Aspherical

-21.7804

0.4965

0.9446

-161.2507

S7

Aspherical

-4.6896

0.5120

1.54,56.1

1.1422

10.8063

S8

Aspherical ...

Embodiment 2

[0092] In Embodiment 2, the lens system satisfies the conditions in the following table:

[0093] table 3

[0094] surface number

thickness

Material

Effective caliber

Conic coefficient

obj

sphere

infinity

infinity

STO

sphere

infinity

-0.1798

0.6959

S1

Aspherical

1.4050

0.4636

1.54,56.1

0.7509

-1.2702

S2

Aspherical

-36.3397

0.0409

0.7697

100.3307

S3

Aspherical

6.0806

0.2004

1.64,23.8

0.8018

55.7987

S4

Aspherical

1.7539

0.2939

0.8363

2.1098

S5

Aspherical

94.7637

0.3868

1.54,56.1

0.9022

-287.1507

S6

Aspherical

-16.8700

0.4755

1.0214

112.3607

S7

Aspherical

-5.7934

0.5326

1.54,56.1

1.1826

5.0169

S8

Aspherical ...

Embodiment 3

[0100] In Embodiment 3, the lens system satisfies the conditions in the following table:

[0101] table 5

[0102] surface number

radius of curvature

thickness

Material

Effective caliber

Conic coefficient

obj

sphere

infinity

infinity

STO

sphere

infinity

-0.1992

0.7403

S1

Aspherical

1.2770

0.4990

1.54,56.1

0.8053

-0.7934

S2

Aspherical

-289.9828

0.0638

0.7976

97.7992

S3

Aspherical

8.4741

0.1336

1.64,23.8

0.7768

68.6934

S4

Aspherical

1.9229

0.3341

0.7656

3.1712

S5

Aspherical

19.1816

0.2652

1.54,56.1

0.8295

-600.0002

S6

Aspherical

25.7297

0.3523

0.9642

-160.8132

S7

Aspherical

-3.2631

0.5701

1.54,56.1

1.0283

7.2718

S8

Aspherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com