High-power and long-life valve-regulated sealed lead-acid batteries for data centers

A lead-acid battery, valve control technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., to achieve the effect of suppressing battery short circuit, reducing polarization and corrosion, and ensuring the design life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

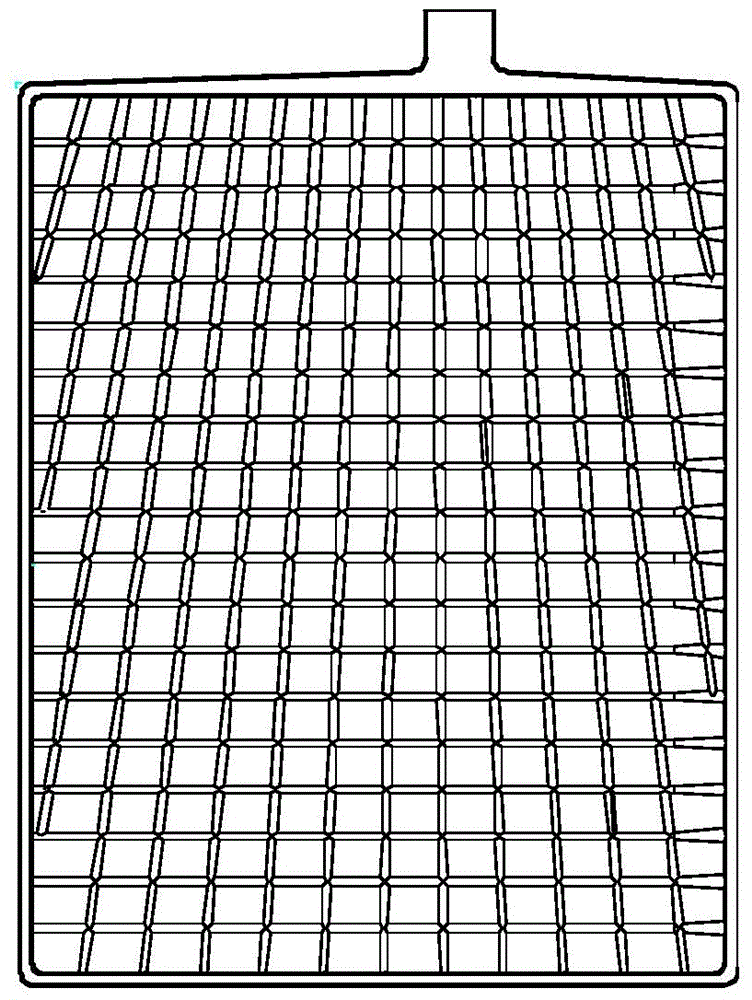

[0020] like figure 1 As shown, in the valve-regulated sealed lead-acid battery of the present invention, the longitudinal ribs of the grid grid are radially distributed, the tabs are centered, and the spacing of the longitudinal ribs is 0.7 to 0.8 times the spacing of the transverse ribs.

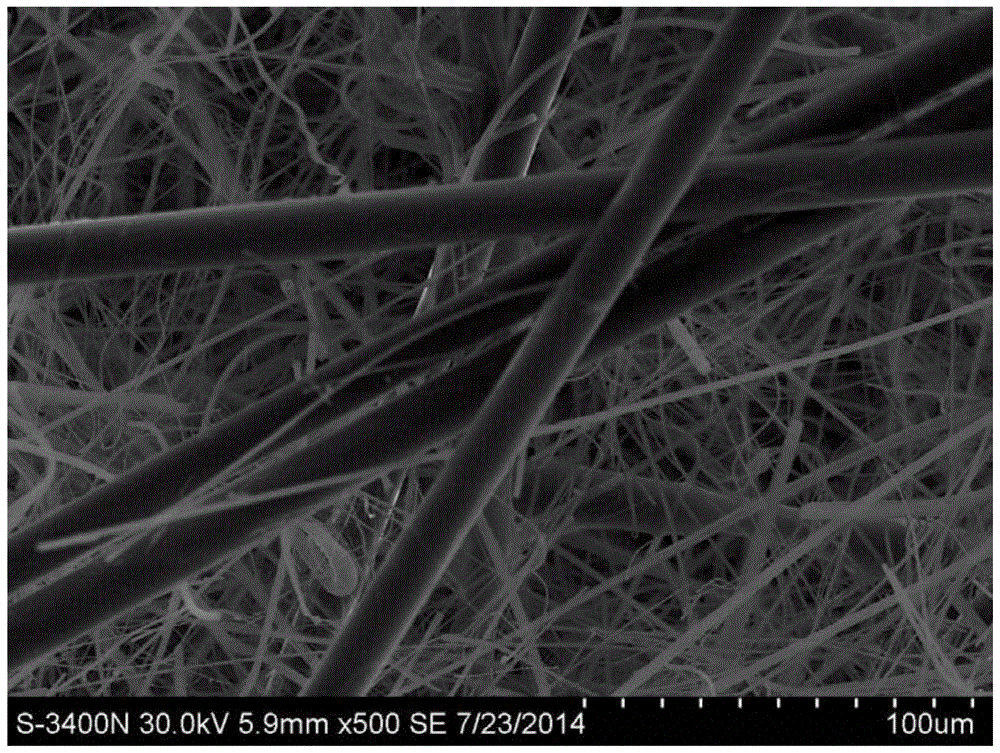

[0021] The γ value of the positive grid is 1.218, the tin content w% of the positive grid alloy is 1.0-1.2%, the calcium content is 0.04-0.05%; the apparent density of the positive electrode paste is 4.2-4.3 g / cm 3 , Negative lead paste formula apparent density 4.3~4.4 g / cm 3 ; After the plate passes through the drying oven, it is stacked by an automatic slicer machine to stack 40-100 pieces, and then fixed by the bracket and sent to the curing iron frame. The porosity of the separator is 94-95%, and the separator is added with organic fiber material , the basis weight of the separator is 145~162 g / mm.m 2 , The acid density of the battery is 1.31~1.33g / cm 3 .

[0022] The valve-controll...

Embodiment 2

[0024] like figure 1 As shown, in the valve-regulated sealed lead-acid battery of the present invention, the longitudinal ribs of the grid grid are radially distributed, the tabs are centered, and the spacing of the longitudinal ribs is 0.7 to 0.8 times the spacing of the transverse ribs.

[0025] The γ value of the positive grid is 1.117, the tin content of the positive grid alloy is 1.0-1.2%, the calcium content is 0.04-0.05%, and the apparent density of the positive electrode paste is 4.1-4.2 g / cm 3 , Negative lead paste formula apparent density 4.3~4.4 g / cm 3 ; After the plate passes through the drying oven, it is stacked by an automatic slicer machine to stack 40-100 pieces, and then fixed by the bracket and sent to the curing iron frame. The porosity of the separator is 94-95%, and the separator is added with organic fiber material , the basis weight of the separator is 145~162 g / mm.m 2 , The acid density of the battery is 1.31~1.33g / cm 3 .

[0026] The valve-control...

Embodiment 3

[0028] like figure 1 As shown, in the valve-regulated sealed lead-acid battery of the present invention, the longitudinal ribs of the grid grid are radially distributed, the tabs are centered, and the spacing of the longitudinal ribs is 0.7 to 0.8 times the spacing of the transverse ribs.

[0029] The γ value of the positive grid is 0.904, the tin content of the positive grid alloy is 1.2-1.5%, the calcium content is 0.04-0.05%, and the apparent density of the positive electrode paste is 4.1-4.2 g / cm 3 , Negative electrode paste formula apparent density 4.4 ~ 4.5 g / cm 3 ; After the plate passes through the drying oven, it is stacked by an automatic slicer machine to stack 40-100 pieces, and then fixed by the bracket and sent to the curing iron frame. The porosity of the separator is 93-94%, and the separator is added with organic fiber material , the basis weight of the separator is 163~176 g / mm.m 2 , The acid density of the battery is 1.30~1.31g / cm 3 .

[0030] The valve-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com