Power cable stripping device

A technology for stripping device and power cable, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of low stripping efficiency, complicated operation and complex structure, and achieve high stripping efficiency, convenient operation and structural design. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

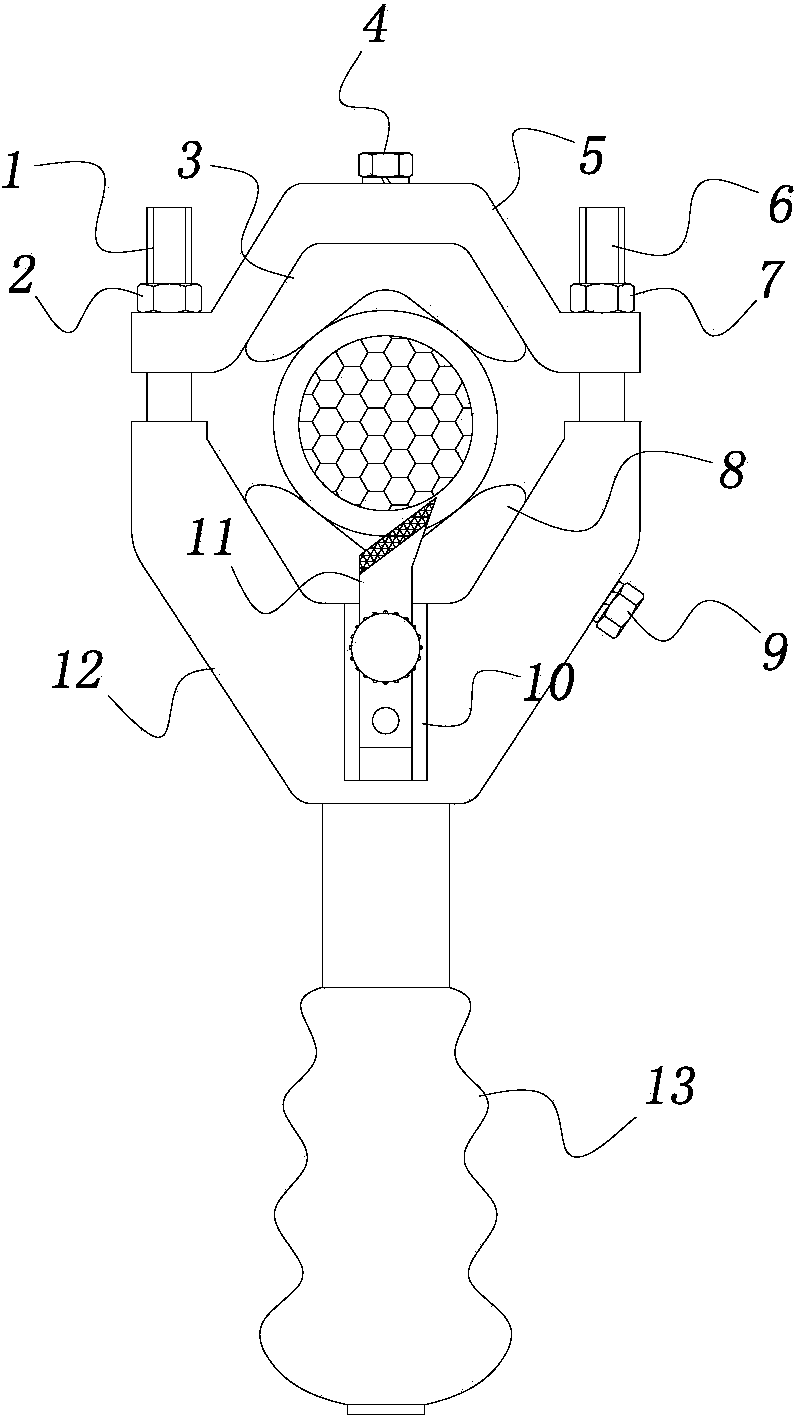

[0011] See figure 1 , the present invention comprises a handle 13, one end of the handle 13 is fixedly connected with a fixed base 12 with a V-shaped notch on the outside, a V-shaped second clamping block 8 is fixedly connected in the V-shaped notch, and the fixed base 12 is also affixed with a knife rest 10, a blade 11 is installed on the knife rest 10, and the cutting edge of the blade 11 is positioned at the clamp groove end face of the second clamping block 8.

[0012] The first guide post 1 and the second guide post 6 parallel to each other are also provided on the fixed base 12, and a movable base 5 with a V-shaped notch inside is also included, and a V-shaped notch is fixed in the V-shaped notch. The first clamp block 3. Both ends of the movable base 5 are provided with shaft holes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com