Wire stand of vertical winding machine

A vertical winding machine and wire rack technology, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of wire wear, complex structure, poor stability of the wire rack, etc. The effect of simple line path and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

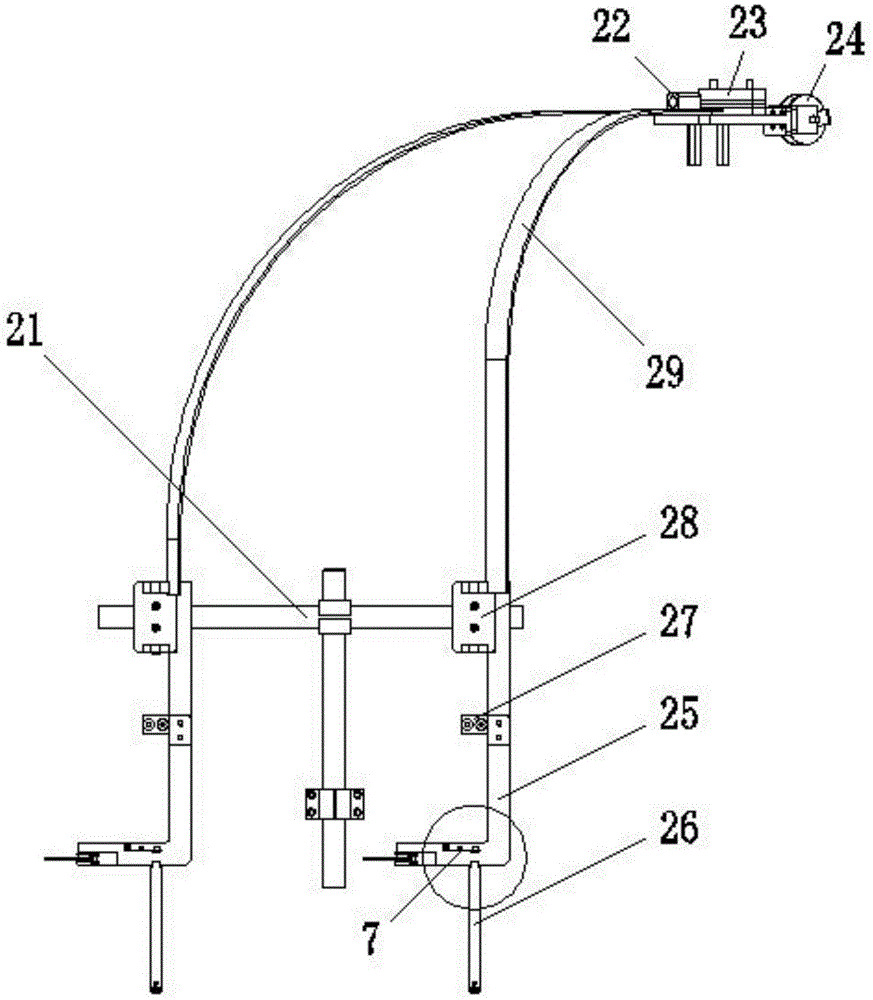

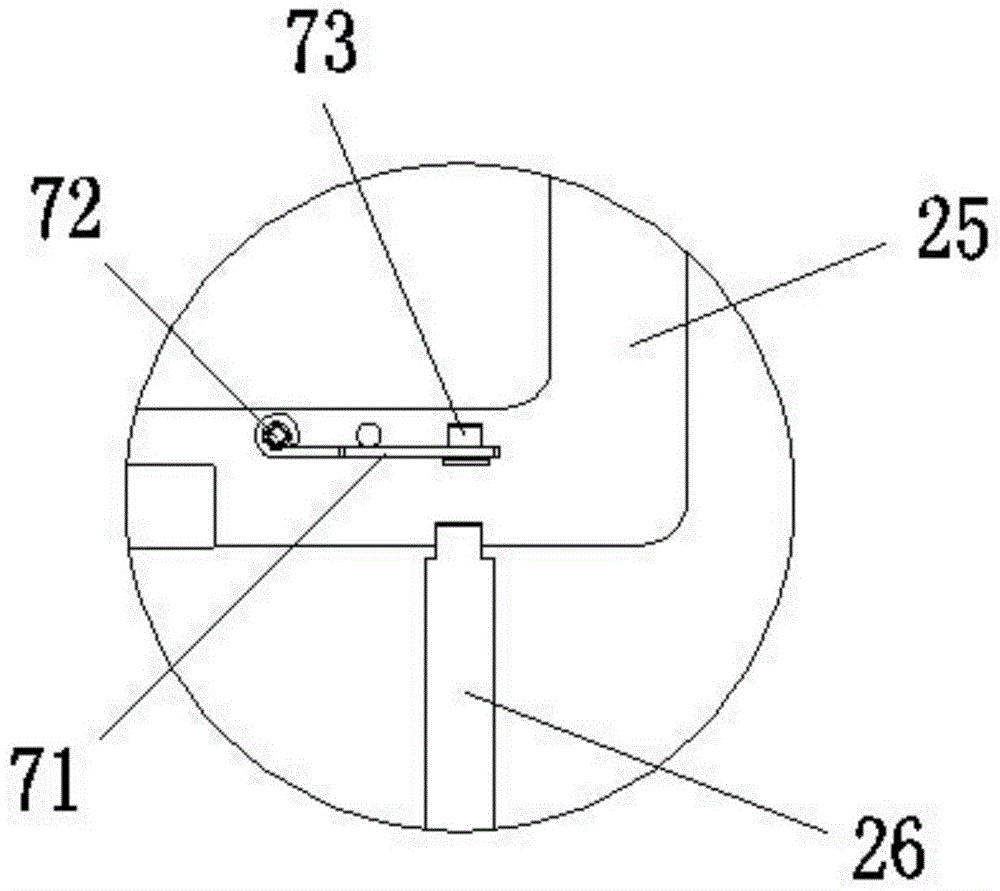

[0012] as attached figure 1 , 2 As shown, the wire frame of a vertical winding machine according to the present invention includes a fixed frame 21, an outlet end assembly and two sets of wire passing assemblies arranged on the fixed frame 21; The threading block 22, the upper stabilizing device 23 and the wire outlet wheel 24 are arranged correspondingly in the direction; Thread protection device 7, lower thread stabilizing device 27, threading plate 28 and arc-shaped thread-passing plate 29; Evenly arranged wire hooks (not shown); the disconnection protection device 7 includes a connecting rod 71 and a knob 72; the knob 72 is rotatably arranged on the mounting plate 25; one end of the connecting rod 71 is arranged on On the knob 72, the other end of the connecting rod 71 is provided with a connecting rod threading hole 73 corresponding to the wiring direction; When wireless in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com