Aerosol spray generation

An aerosol and spray chamber technology, applied in the field of generating aerosol spray, can solve problems such as the sound quality or acoustics of aerosol spray that have not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

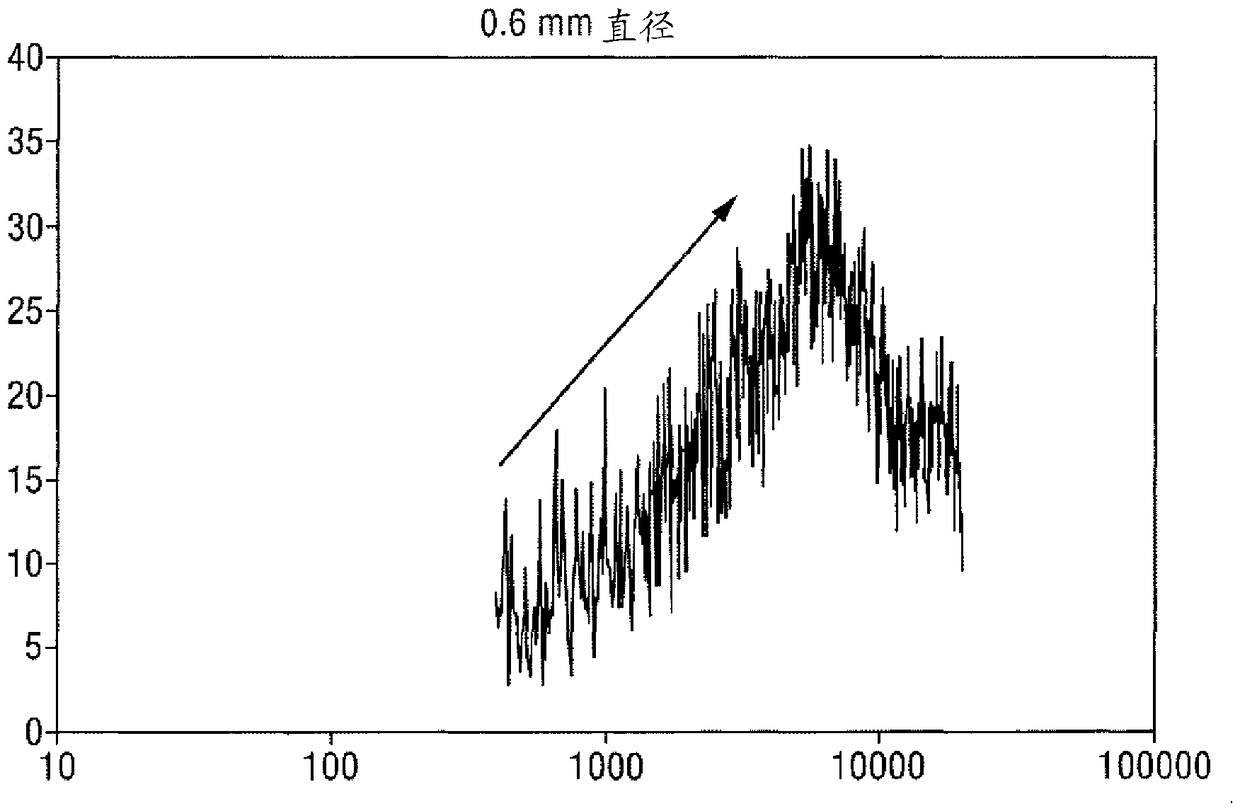

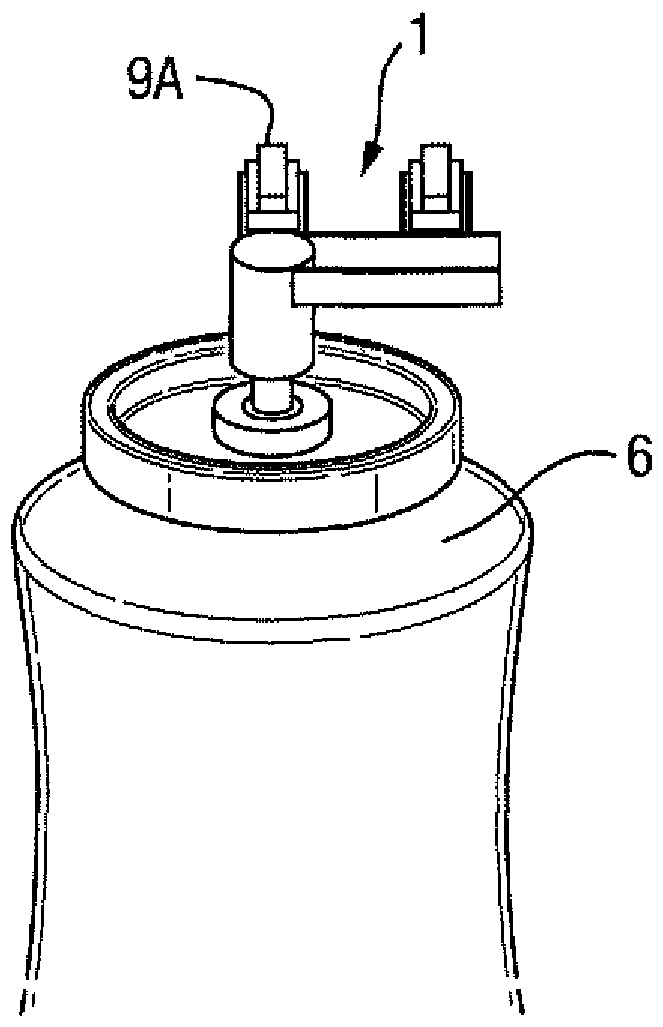

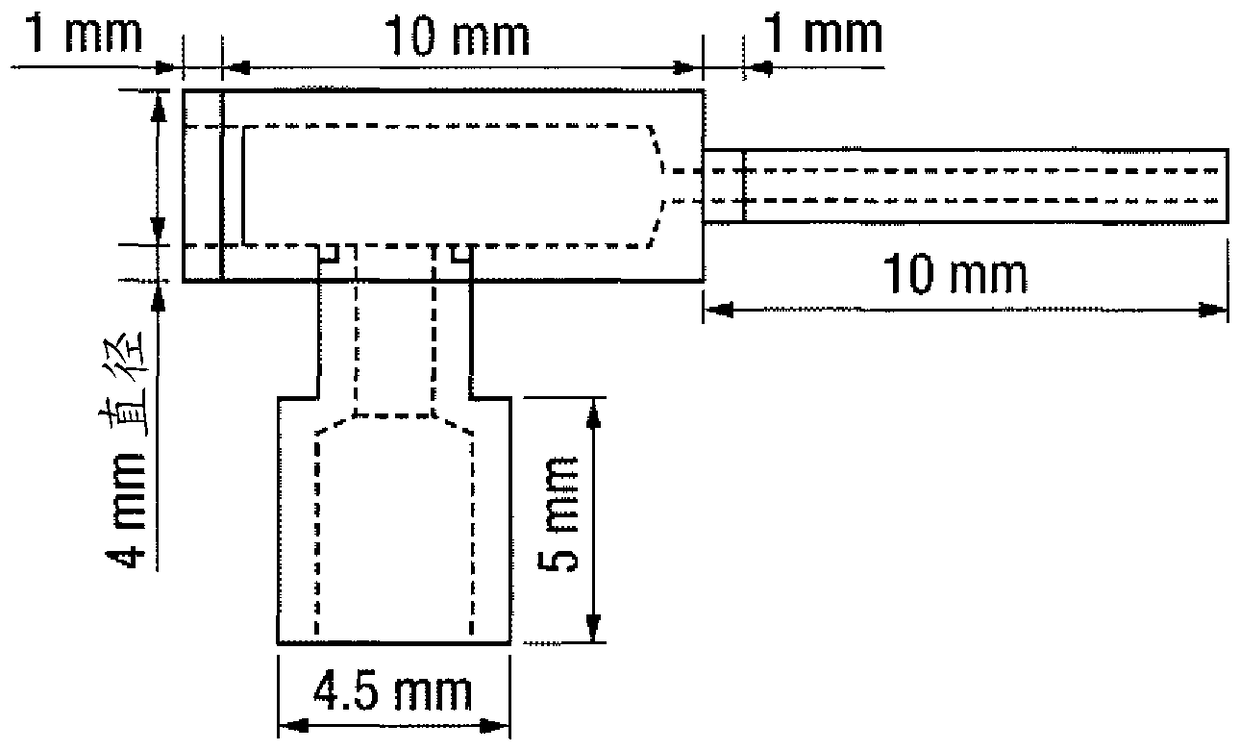

[0060] In the first series of experiments, a number of spray line components were evaluated. Figures 1 to 4 show the structural arrangements used. The part fits in the groove 7 of the aluminum "panel" 1 and consists of an upper half 4 and a lower half 5 which in turn is connected to a commercially available antiperspirant aerosol product 6 (175 ml Dove TM Antiperspirant spray aerosol, spray down to 75% fill level before use). The screed rests on the valve stem of the aerosol bottle 6 so that downward pressure on the screed 1 causes the valve to open and allow release of the pressurized contents therein. The valve stem is loaded into the template 1 through a channel 8 in the underside of chamber 9 of the template 1 which is connected to the first section 2A or 2B of the spray pipe (see Figure 1A and 1B ) in fluid communication. The first section of the spray conduit 2A or 2B is held in close proximity and in fluid communication with the second (terminal) section 3 of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com