Method of reducing combustion induced oscillations in turbine engine

A technology of turbine engine and combustion chamber, which is applied in the direction of combustion method, engine function, engine control, etc., and can solve problems such as mechanical fatigue of engine components, adverse effects of engine, thermal fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

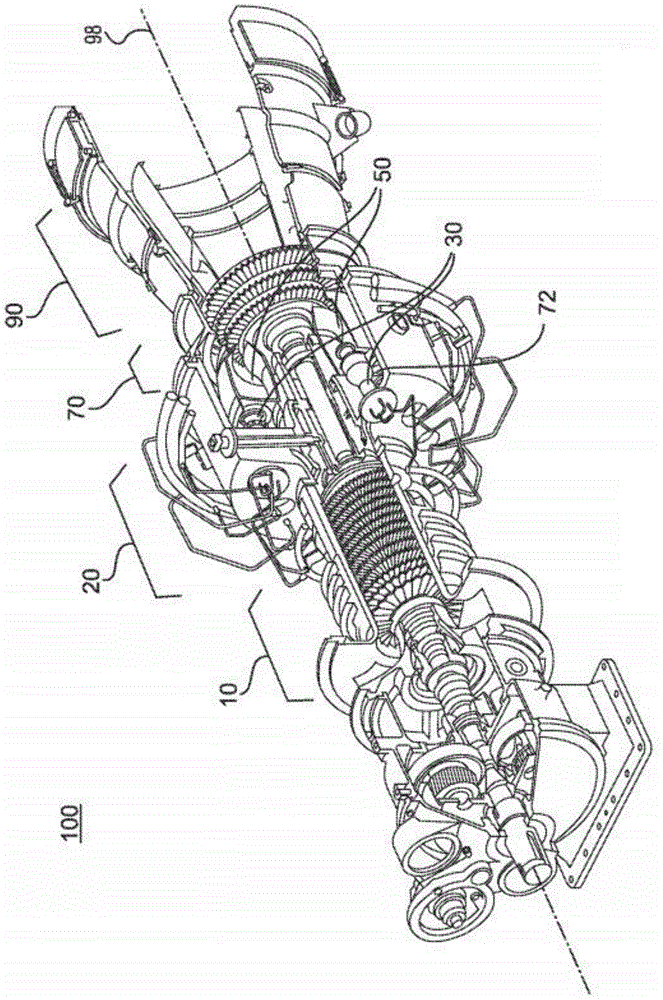

[0017] figure 1 An exemplary gas turbine engine (GTE) 100 is shown. GTE 100 may have, among other systems, compressor system 10 , combustor system 20 , turbine system 70 and exhaust system 90 arranged along engine axis 98 . Compressor system 10 compresses air and delivers the compressed air to enclosure 72 of combustor system 20 . Compressed air is directed from the enclosed volume 72 into one or more fuel injectors 30 positioned therein. The compressed air is mixed with fuel in fuel injector 30 , and the fuel-air mixture is directed to a combustion chamber (combustion chamber 50 ). The fuel air mixture is ignited and combusted in the combustor 50 to produce high pressure and high temperature combustion gases. These combustion gases are then directed to turbine system 70 . A turbine system 70 extracts energy from these combustion gases and directs the exhaust gases to the atmosphere through an exhaust system 90 .

[0018] Liquid fuel (eg, diesel, kerosene, etc.) or gaseou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com