Organic electroluminescent element, organic electroluminescent lighting device, and organic electroluminescent display device

一种电致发光元件、致发光的技术,应用在电致发光光源、照明装置、电气元件等方向,能够解决产生浓度分布、溶解性差、电荷输送材料与发光材料溶解性差等问题,达到驱动电压低、电能效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

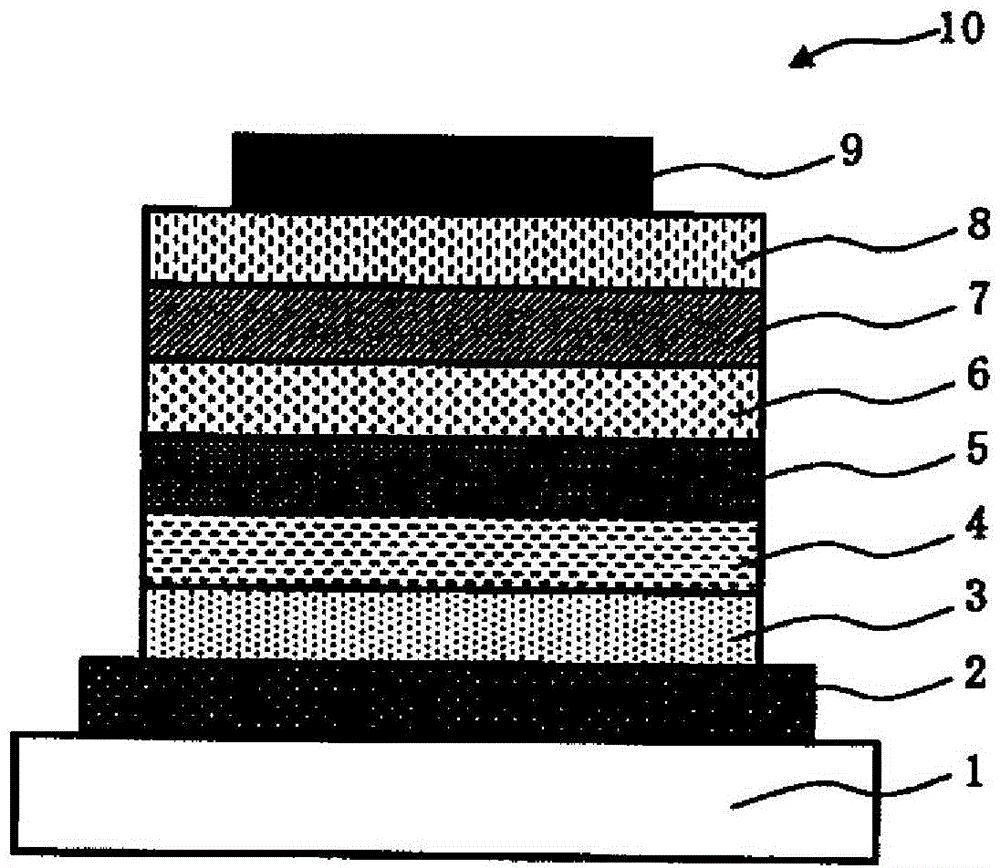

[0611] An organic electroluminescent element was produced in the following steps.

[0612] After depositing an indium tin oxide (ITO) transparent conductive film on the glass substrate 1 by sputtering, a common photolithography technique and hydrochloric acid etching were used to pattern 2 mm wide stripes to form the anode 2 . After patterning, the ITO substrate is cleaned in the order of ultrasonic cleaning with aqueous surfactant solution, water washing with ultrapure water, ultrasonic cleaning with ultrapure water, and water washing with ultrapure water, then dried, and then UV ozone cleaning .

[0613] Next, a polymer containing arylamine shown in the following structural formula (P-1), 4-isopropyl-4'-methyldiphenyliodonium tetrakis( A composition for forming a hole injection layer having the following composition of pentafluorophenyl) borate and ethyl benzoate. The composition for forming a hole injection layer was formed into a film on the anode 2 by spin coating under...

Embodiment 2

[0654] Using compounds (H-1), (E-1) and compound (H-2) shown below as the charge transporting material of the composition for forming a light-emitting layer, a composition for forming a light-emitting layer prepared with the following composition was used, except Otherwise, an organic electroluminescence element was fabricated in the same manner as in Example 1. The properties of the obtained elements are listed in Table 1.

[0655] [chem 79]

[0656]

[0657]

[0658]

Embodiment 3

[0660] Compounds (H-1), (E-1) and compound (H-3) shown below were used as the charge transport material of the composition for forming a light-emitting layer, and compound (B2) shown below was used instead of the compound of the light-emitting material (B1) Except having used the composition for light emitting layer formation prepared by the following composition, it carried out similarly to Example 1, and produced the organic electroluminescent element. The properties of the obtained elements are listed in Table 1.

[0661] [chem 80]

[0662]

[0663]

[0664]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com