A method for removing damaged blades of an aeroengine stator assembly

A technology of aero-engines and blades, which is applied in the direction of electric processing equipment, electrode manufacturing, and auxiliary devices, etc., can solve the problem of not removing damaged blades, and achieve the effect of reducing maintenance costs and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] A method for removing damaged blades of an aero-engine stator assembly comprises the steps of:

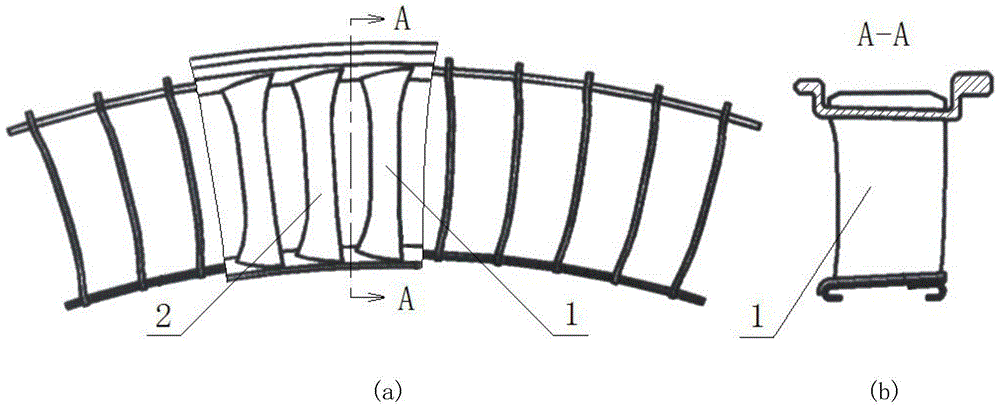

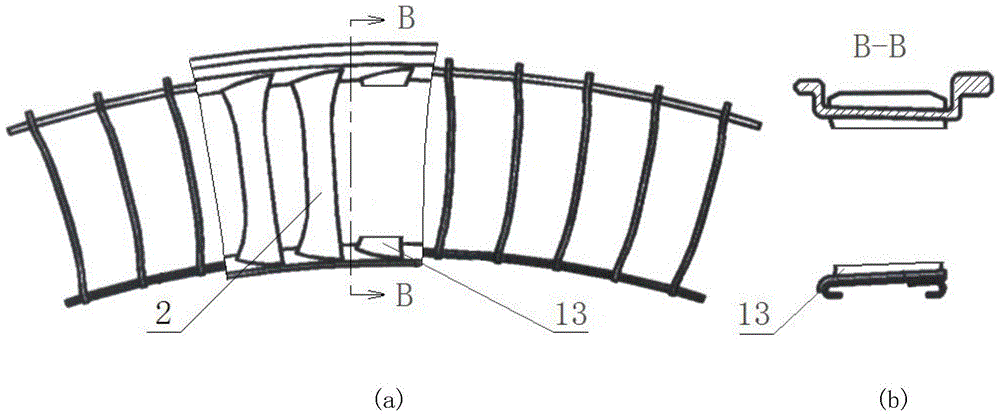

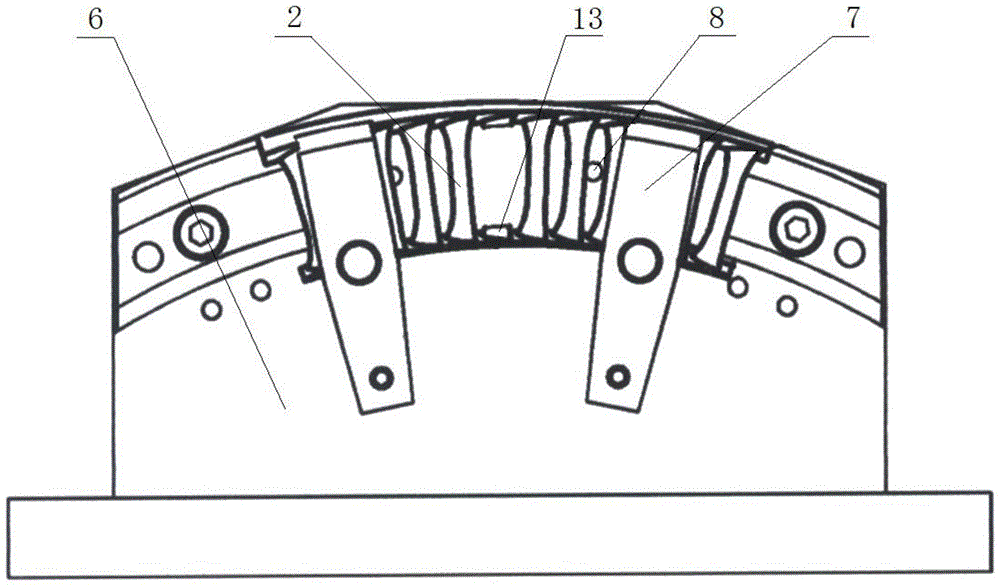

[0024] Step 1: Use wire cutting equipment to remove most of the blade body of the damaged blade 1. During the cutting process, on the premise of not destroying the inner and outer ring blade plates, reduce the residual amount of the blade as much as possible; after the wire cutting is completed, the fan section The remaining blades 13 on the stator assembly have three profiles, which are respectively the residual blades 13 located on the T-shaped blade plate 3, the flow channel blade plate 4 and the large curved edge blade plate 5;

[0025] Step 2: Clamp the segment stator assembly that has been wire-cut into the positioning tool;

[0026] Step 3: Send the segment stator assembly and its positioning tool into the EDM machine tool, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com