Two-plate mold closing machine for moving molds in one direction

A two-plate type, clamping machine technology, applied in the field of clamping machines, can solve the problems of high energy consumption, short service life, large volume, etc., achieve uniform pressure distribution, reduce damage and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

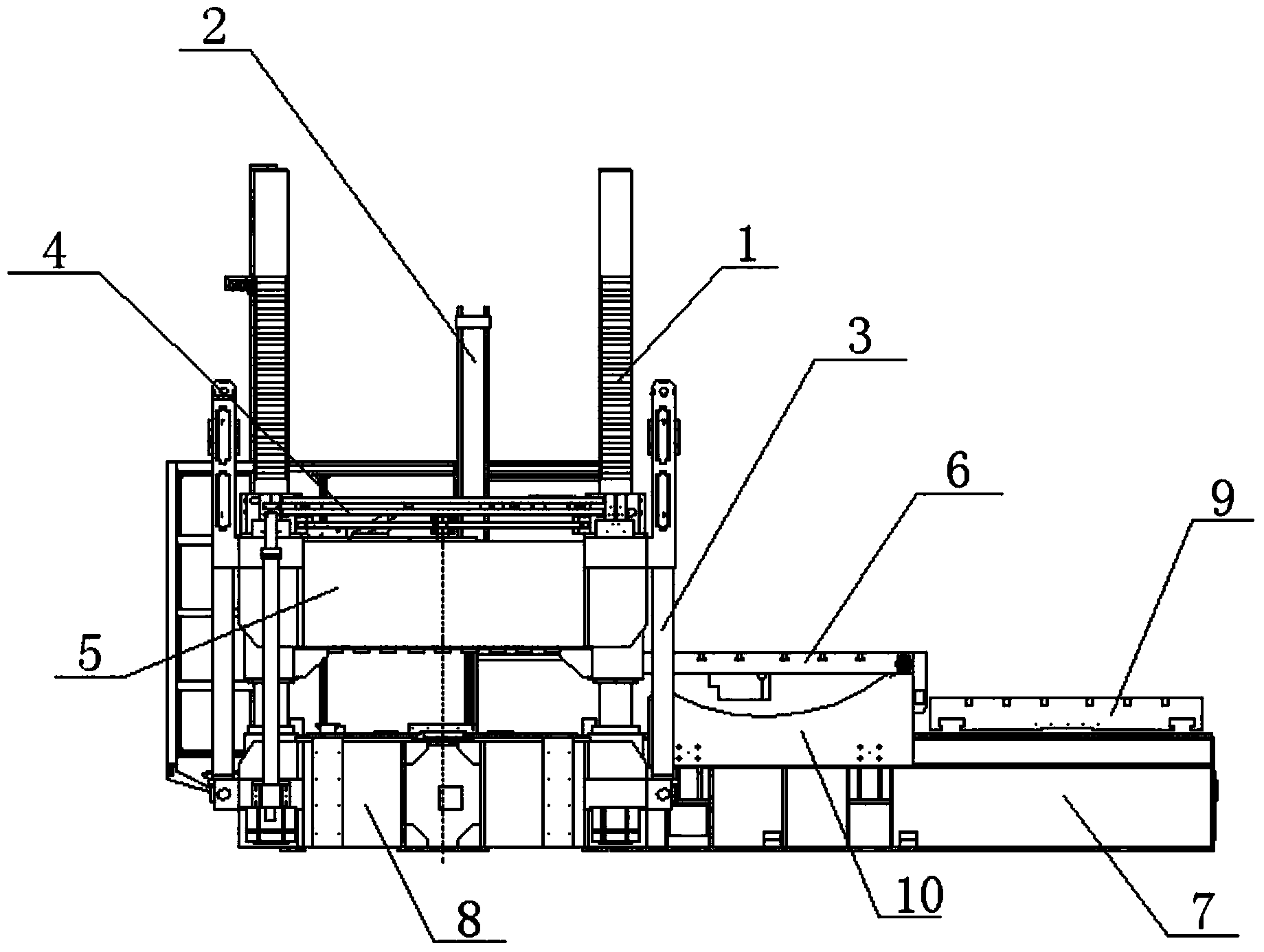

[0027] There are 4 high-pressure mold-clamping oil cylinders, which form a square and are arranged in the middle of the lower seat. During high-pressure mold-locking, they are pressed against the lower template moved in to play a high-pressure mold-locking role. The upper part of the mold acts as a clamping force.

[0028] The upper base 5 slides up and down along the pull rod through the fast oil cylinder 3 at the lower end, and the brake nut 12 at the upper end of the upper base 5 realizes the simultaneous brake through the control of the brake synchronization device 4, so that the upper base 5 is fixed at a certain height on the pull rod , when the mold is opened, the mobile lower template 9 on the lower mold removal seat 7 first moves outward to one end of the lower mold removal seat 7, and then the turnover template 6 can be turned around the hinge through the action of the turning cylinder 2 and the upper seat 5 Rotate, one end of the flip template 6 slides along the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com