A special railway crane

A technology of truck-mounted cranes and railways, which is applied in the direction of cranes, etc., which can solve the problems of inability to lift heavy objects at close distances, small operating range of cranes, and potential safety hazards, and achieve the effects of improving operating efficiency, avoiding multiple hoisting, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

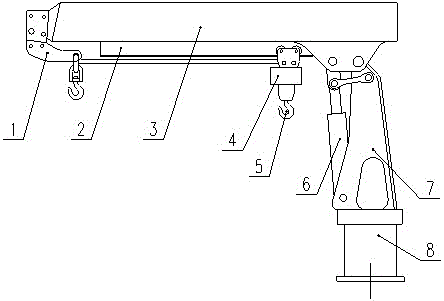

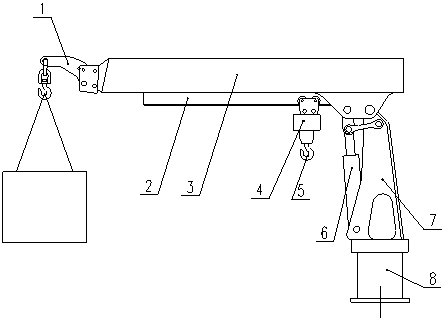

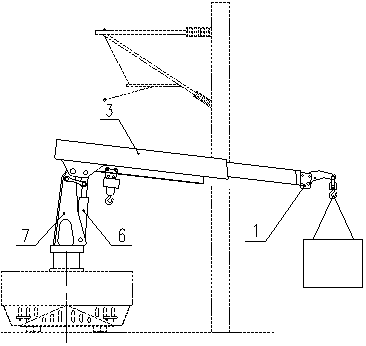

[0018] figure 1 , figure 2 Among them, one end of the boom 3 is hinged to the turntable 7. The boom 3 includes a rotary arm connected to the turntable 7, and a telescopic arm that is installed in the rotary arm and can extend along the rotary arm. One end of telescopic oil cylinder 6 is contained on the turntable 7, and one end is contained in the lower end of the rotating arm, in order to control the rotating arm to rotate around the hinge point. The outer end of the telescopic arm is connected with a hook support arm 1 . The hook support arm 1 is mounted on the outer end of the telescopic arm through the mounting seat; the mounting seat includes two parallel mounting plates mounted on the telescopic arm; a mounting shaft is installed between the two mounting plates; the hook support arm 1 is mounted on The shaft is installed and can rotate along the shaft; the hook arm 1 is provided with a positioning hole, and the mounting plate is provided with a plurality of mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com