Method for preparing flame-retardant orange essential oil-based vinyl ester resin monomer

A technology of oil-based vinyl ester and resin monomers, which is applied in the field of preparation of flame-retardant bio-based vinyl ester resin monomers, can solve the problems of poor weather resistance, poor flame retardancy, and high content of toxic components, and achieve improved comprehensive performance , Improve the effect of poor flame retardancy and weather resistance, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

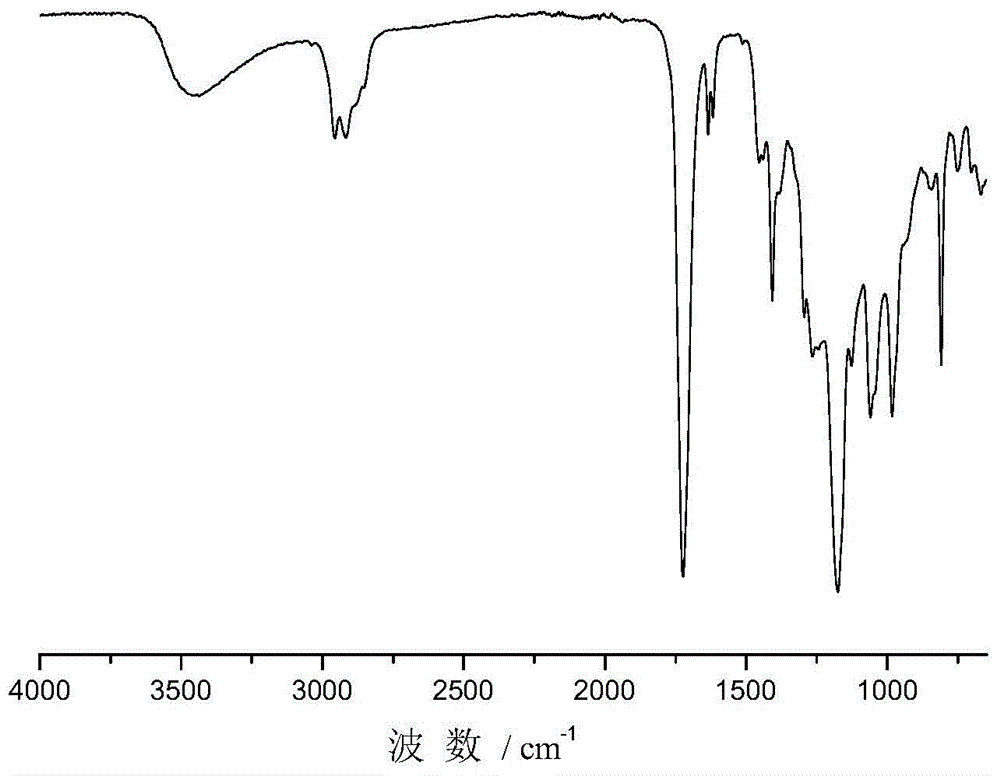

Image

Examples

Embodiment 1

[0026] Add maleic anhydride into the reactor, raise the temperature to 70°C, make it melt completely, add orange essential oil dropwise according to the molar ratio of orange essential oil and butenedioic anhydride as 1.3:1, raise the temperature to 180°C, and react After 5 h, the impurities were removed by distillation under reduced pressure to obtain the intermediate product orange essential oil-based anhydride; then distilled water was added dropwise at a molar ratio of 1:1 to the orange essential oil-based anhydride, and condensed and refluxed at 100 °C for 2.0 h to obtain orange essential oil base dicarboxylic acids. Add DOPO with a molar ratio of DOPO to orange essential oil-based dicarboxylic acid of 0.6:1 to the prepared orange essential oil-based dicarboxylic acid, heat to 160 °C, and react for 3 h to obtain flame-retardant orange essential oil-based dicarboxylic acid acid. Add the flame-retardant orange essential oil-based dicarboxylic acid and epichlorohydrin into ...

Embodiment 2

[0029] Add fumaric anhydride to the reactor, heat up to 65°C, make it melt completely, add orange essential oil dropwise at a ratio of 1.25:1 molar ratio of orange essential oil to fumaric anhydride, heat up to 170°C, After reacting for 4.5 h, remove impurities by distillation under reduced pressure to obtain the intermediate product orange essential oil anhydride; then add distilled water dropwise at a molar ratio of 1:1 to orange essential oil anhydride, condense and reflux at 100 °C for 2.0 h to obtain orange Essential oil based dicarboxylic acid. Add DOPO with a molar ratio of DOPO to orange essential oil-based dicarboxylic acid of 0.4:1 to the prepared orange essential oil-based dicarboxylic acid, heat to 155 °C, and react for 3.5 h to obtain flame-retardant orange essential oil-based dicarboxylic acid acid. Add the flame-retardant orange essential oil-based dicarboxylic acid and epichlorohydrin into the reactor according to the molar ratio of 1:8, and add 0.75% of the q...

Embodiment 3

[0032]Add itaconic anhydride into the reactor, raise the temperature to 75 °C, make it melt completely, add orange essential oil dropwise according to the ratio of orange essential oil to itaconic anhydride molar ratio of 1.2:1, raise the temperature to 200 °C, react for 4 h, reduce Press distillation to remove impurities to obtain the intermediate product orange essential oil-based anhydride; then add distilled water dropwise at a molar ratio of 1:1 to orange essential oil-based anhydride, and condense and reflux for 1.5 h at 105 °C to obtain orange essential oil-based dicarboxylic acid acid. Add DOPO with a molar ratio of DOPO to orange essential oil-based dicarboxylic acid of 0.75:1 to the prepared orange essential oil-based dicarboxylic acid, heat to 180 °C, and react for 2 h to obtain flame-retardant orange essential oil-based dicarboxylic acid acid. Add the flame-retardant orange essential oil-based dicarboxylic acid and epichlorohydrin into the reactor according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com