Disperse blue-to-black dye composition

A black dye and composition technology, applied in the direction of organic dyes, etc., can solve the problems of too sensitive pH value, poor vat, and unstable dyeing, etc., and achieve a wide range of pH resistance, outstanding alkali resistance, and excellent color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

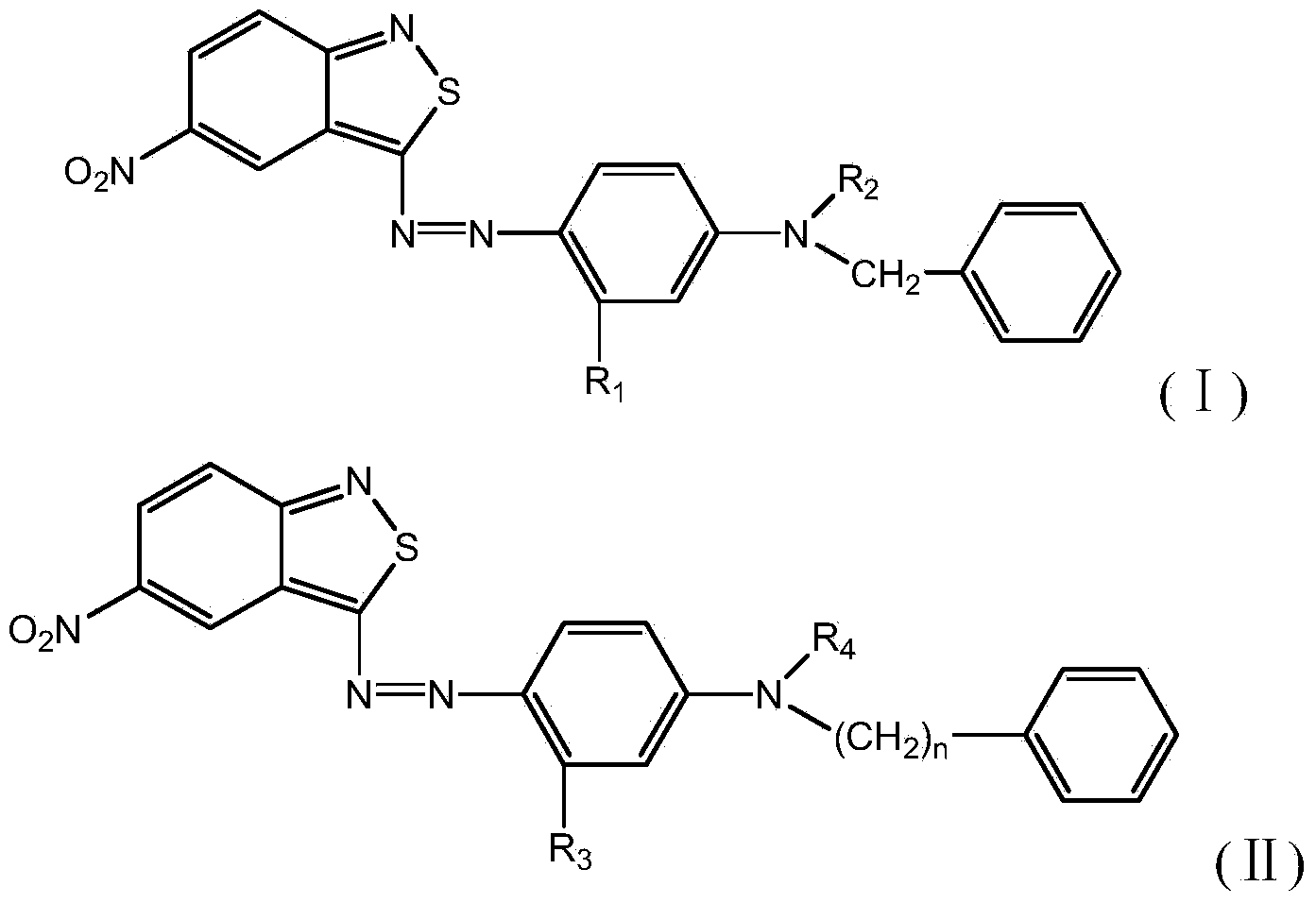

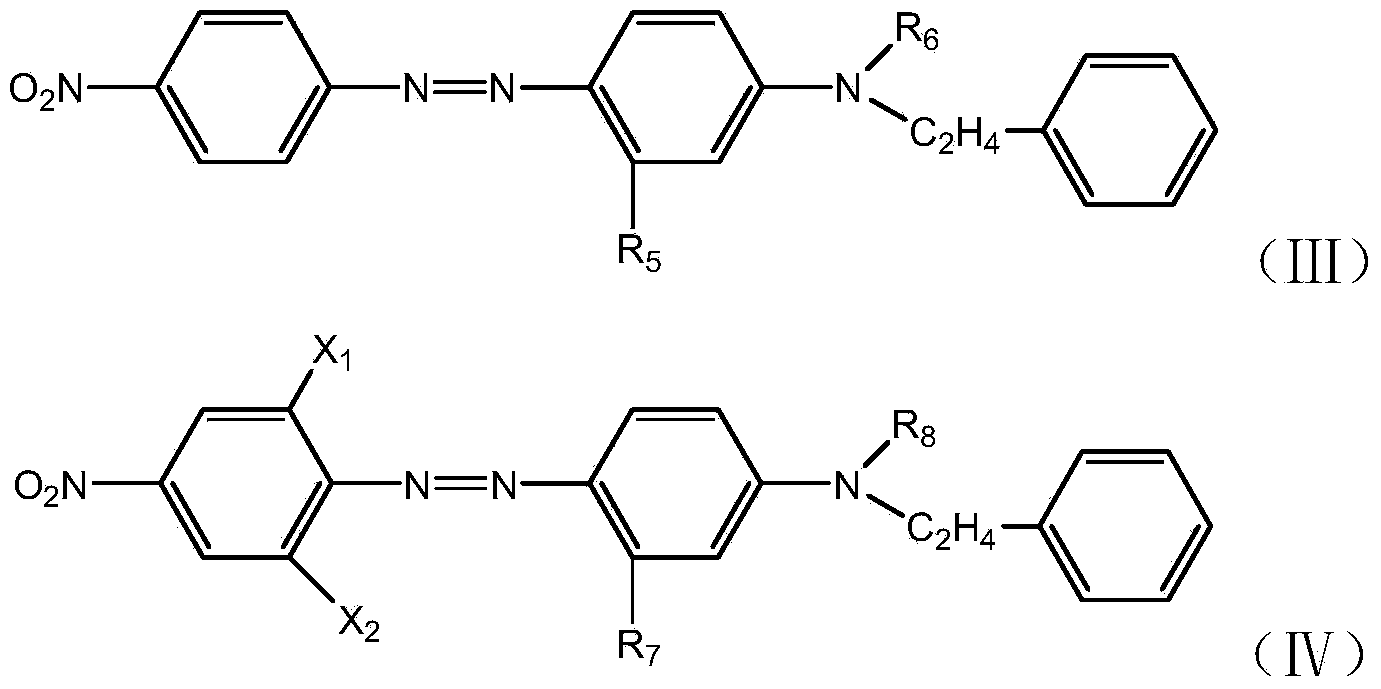

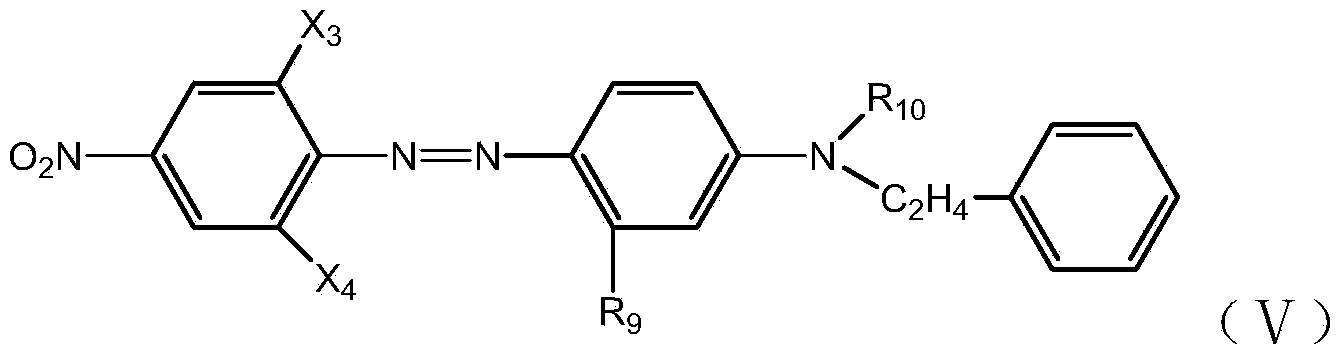

Method used

Image

Examples

Embodiment l

[0043] Mix 55 grams of formula (I-1), 45 grams of formula (Ⅲ-1), 250 grams of dispersant MF, and add 550 grams of water, grind and disperse and dry to obtain the finished product, which can provide fabric black tone .

Embodiment 2

[0045] Mix 75 grams of formula (I-1), 18 grams of formula (III-1), 7 grams of formula (V-1), 200 grams of dispersant MF, add 550 grams of water, grind, disperse and dry to obtain the finished product. The finish provides a blue shade to the fabric.

Embodiment 3~32

[0047] According to the method described in Example 1, the difference is that component A, component B and auxiliary agents of the weight shown in Table 1 are used, and water is added to blend to make a slurry, and the solid content of the control slurry is 35 to 45%. It is advisable to grind and disperse and dry to obtain disperse dyes, which are suitable for one-bath and one-step dyeing of polyester fibers and their blended fabrics under alkaline conditions and combined pretreatment and dyeing.

[0048] Table 1

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com