Steel tower column with positioning structure and hoisting construction method thereof

A technology of positioning structure and construction method, applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve problems that are not conducive to the construction quality and safe construction control of steel towers, increase the difficulty of precise positioning of towers, and increase installation costs. and other problems, to achieve the effect of ensuring the overall alignment and construction quality, shortening the hoisting construction period, and ensuring the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

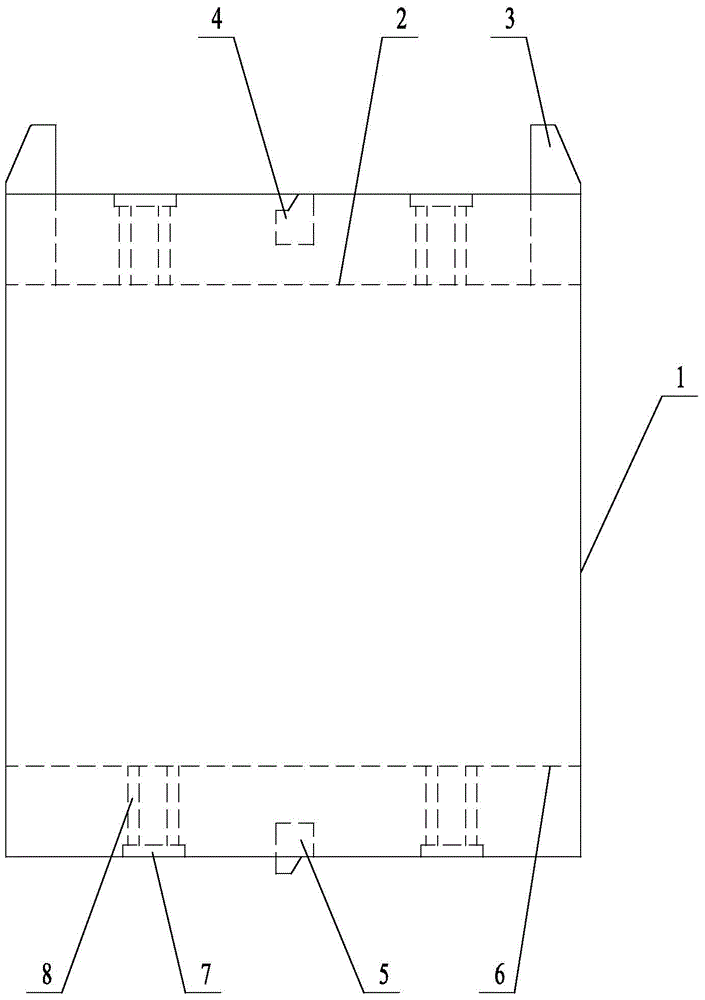

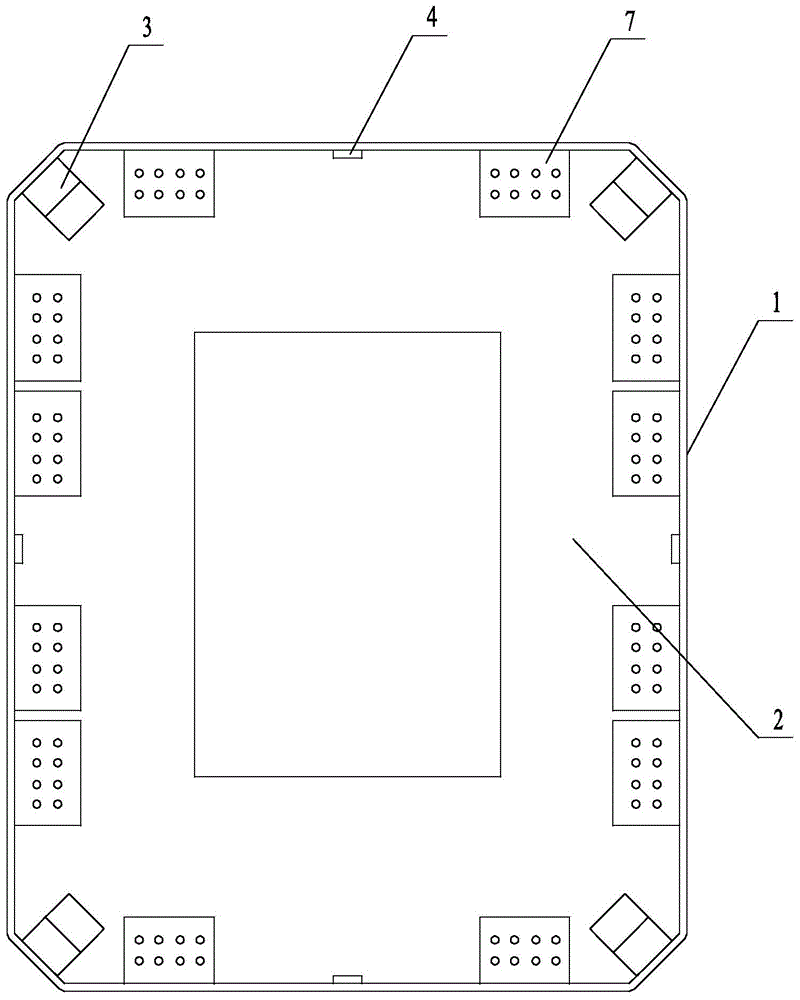

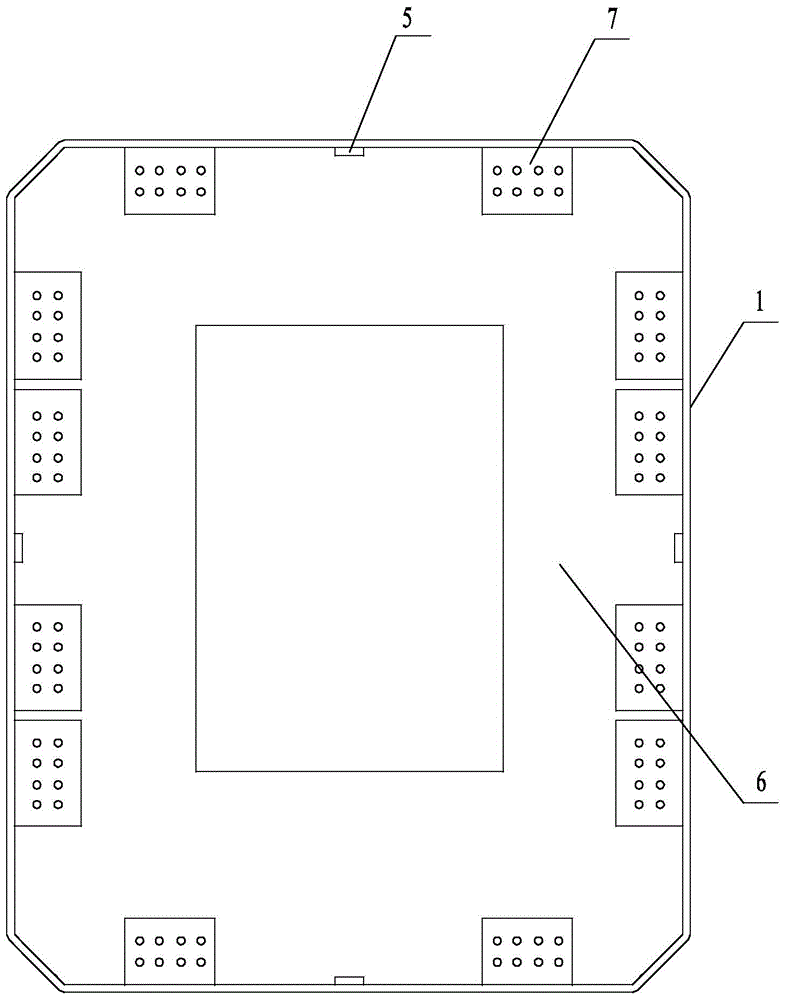

[0033] Such as Figure 1 to Figure 3 As shown, a steel tower column with a positioning structure includes a square steel pipe 1 and a positioning structure. The positioning structure includes an upper mounting plate 2, a lower mounting plate 6, a guide column 3, an upper guide plate 4, a lower guide plate 5 and matching Item 7. The four side corners of the square steel pipe 1 are respectively chamfered into four side edges, the square steel pipe 1 is provided with a horizontal upper mounting plate 2 adjacent to the top opening, and the square steel pipe 1 is provided with a horizontally installed upper mounting plate 2 adjacent to the bottom opening. The lower mounting plate 6, the upper mounting plate 2 and the lower mounting plate 6 middle part are provided with holes, and stairs are set between the upper mounting plate 2 and the lower moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com