A method and device for preventing and controlling gas overrun in thick coal seam mining

A mining process, thick coal seam technology, applied in the direction of gas discharge, mining fluid, safety devices, etc., can solve the problems of reduced gas extraction volume, inability to increase efficiency in thick coal seams, and greater influence of stress distribution, to achieve increased permeability and air permeability, reducing the amount of gas outflow, and improving the drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

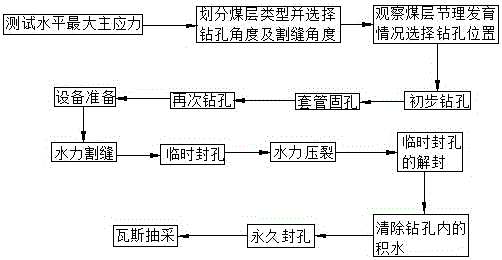

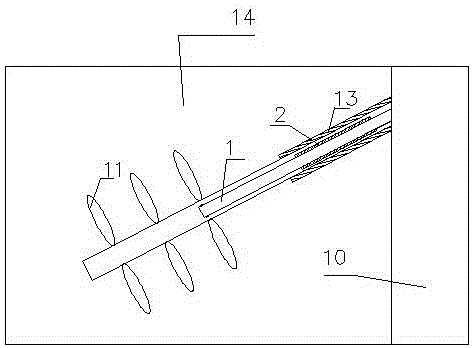

[0038] Example 1, such as figure 1 , figure 2 and image 3 The method for preventing and controlling gas exceeding the limit in the thick coal seam mining process is shown,

[0039] The method includes:

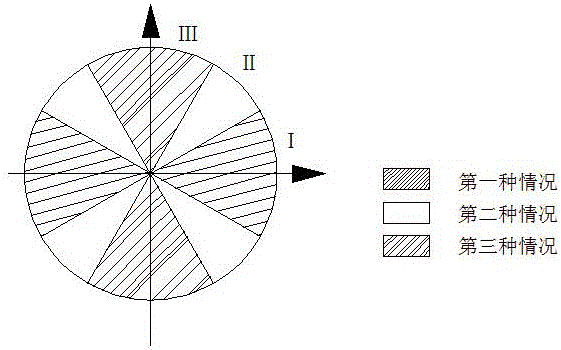

[0040] 1) Selection of drilling location: enter the roadway of coal seam 14, observe the development of joints in coal seam 14, and select a coal seam with relatively developed coal seam joints, because when the development of coal seam joints is relatively good, the connectivity of the drill hole is good, which will cause difficulties in sealing the hole. By selecting the location where the coal seam joints are relatively developed, the difficulty of sealing holes in the subsequent steps can be reduced, thereby improving efficiency. The development of joints can be divided into three situations. The more developed joints here refer to the development of joints in the coal seam 14, but the density is not large. ;

[0041] 2) Selection of drilling angle: test the directio...

Embodiment 2

[0062] Embodiment 2, when the direction of the original ground and the maximum principal stress is 0-30°, the drilling angle is selected to be 45°, the depth of the preliminary drilling is 4m in the compaction zone, and the length of the two-way expander is 8m. In this embodiment Other content is with embodiment 1.

Embodiment 3

[0063] Embodiment 3, when the direction of the original ground and the maximum principal stress is 0-30°, the drilling angle is selected to be 60°, the depth of the preliminary drilling is 5m within the degree of compaction, and the length of the two-way expander is 10m. In this embodiment Other content is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com