Odor removal and inflaming retarding type aluminum and plastic composite pipe

An aluminum-plastic pipe and flame-retardant technology, which is applied in the field of deodorant and flame-retardant aluminum-plastic pipes, which can solve the problems of easy combustion and peculiar smell in case of fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

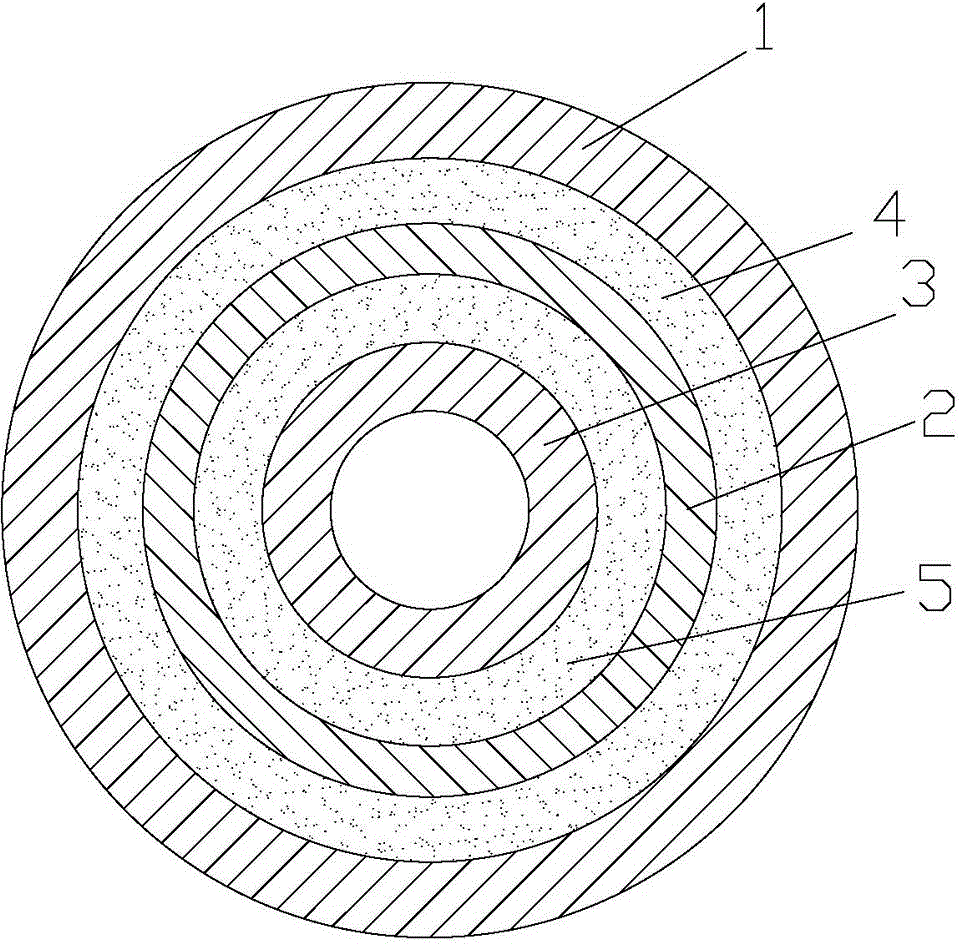

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

[0028] like figure 1 As shown, a deodorizing and flame-retardant aluminum-plastic pipe includes a polyethylene plastic outer layer 1, a first glued layer 4, an aluminum pipe 2, a second glued layer 5 and a polyethylene plastic inner layer 3 from outside to inside, It is characterized in that a flame retardant is added to the polyethylene plastic outer layer 1; a deodorant is added to the polyethylene plastic inner layer 3;

[0029] The polyethylene plastic outer layer 1 comprises the following components by weight percentage:

[0030] Polyethylene resin 50;

[0031] Silica 20;

[0032] Masterbatch 10;

[0033] Tetrabromobisphenol A 10;

[0034] Flame retardant 10;

[0035] Among them, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap