Flow error correction method for time difference type ultrasonic heat meter

An error correction and ultrasonic technology, applied in the field of time difference ultrasonic heat meter flow error correction, can solve the problems of inability to guarantee errors, low production efficiency, and inability to guarantee the accuracy of flow measurement errors, so as to improve production efficiency and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

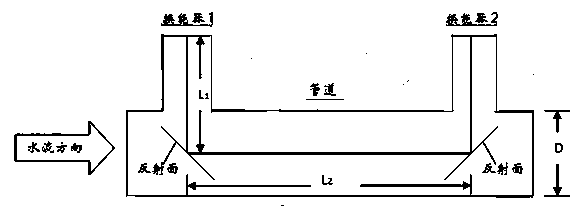

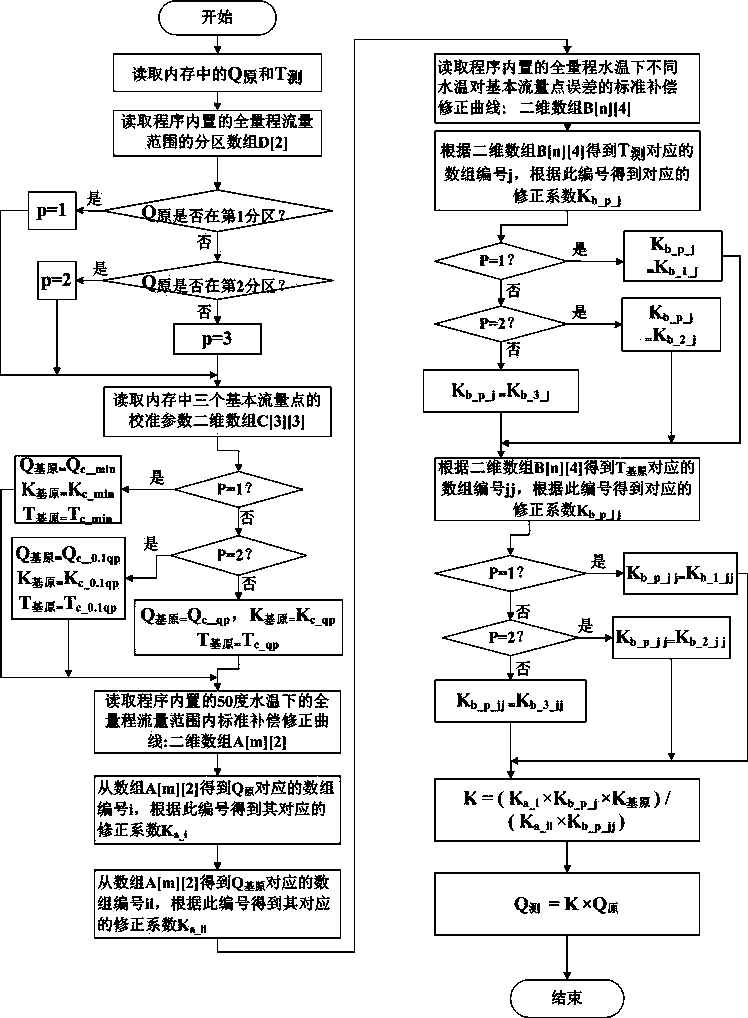

[0029] Such as figure 1 As shown, the present invention is mainly suitable for the flow measurement of the transit-time ultrasonic heat meter. The flow measurement of the transit-time ultrasonic heat meter refers to the application of a pair of ultrasonic transducers to send and receive ultrasonic waves alternately (or simultaneously), and to indirectly measure the flow velocity of the fluid by observing the time difference between the downstream and countercurrent propagation of the ultrasonic waves in the medium, and then pass the flow velocity to calculate flow.

[0030] The transit-time flow measurement method first obtains the relevant time data according to the following formula.

[0031] T 1 = 2 L 1 C + L 2 C + V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com