A temperature conversion method and low-power high-precision integrated temperature sensor

A temperature sensor and conversion method technology, applied in the field of sensors, can solve the problems of large temperature error, increased circuit complexity and power consumption, and low use value, and achieve the effects of simplifying the circuit structure, reducing temperature error, and reducing circuit power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

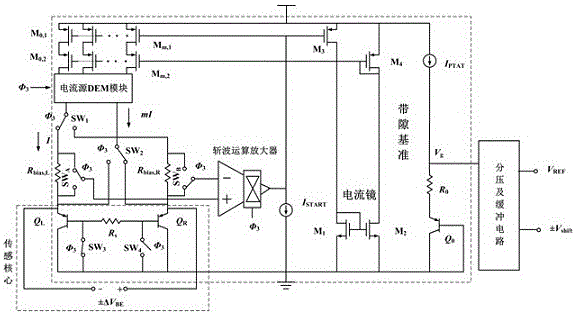

[0034] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] First, the brief working principle of the traditional temperature sensor is explained:

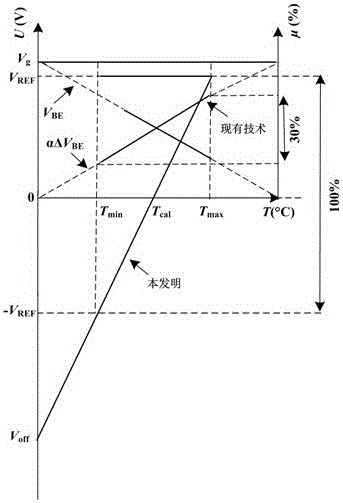

[0036] The base-emitter voltage (base-emitter voltage, V BE ) difference ΔV BE It is proportional to the absolute temperature (Proportional To Absolute Temperature, PTAT), and it is linearly amplified to a suitable amplitude to obtain V PTAT . Just generate a temperature-independent reference voltage (reference voltage, V REF ) to V through an analog-to-digital converter (Analog to Digital Converter, ADC) PTAT Quantification and simple linear processing can get the digital output of the current ambient temperature, which is called the ratio-metric measurement principle. Due to the limitations of the N-well process for standard CMOS integrated circuits, only parasitic substrate PNP transistors can be used, and the collector must always be connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com