Dynamic sealing life testing verifying method of folding rotating mechanism of oil-gas channel

A rotating mechanism and life test technology, which is applied in the testing of machines/structural components, testing of mechanical components, measuring devices, etc., can solve the problems of poor application, small rotation angle, and inability to transplant the design form of the mechanism, etc., to achieve good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] A dynamic seal life test verification method for an oil-gas path folding rotating mechanism of the present invention comprises the following steps:

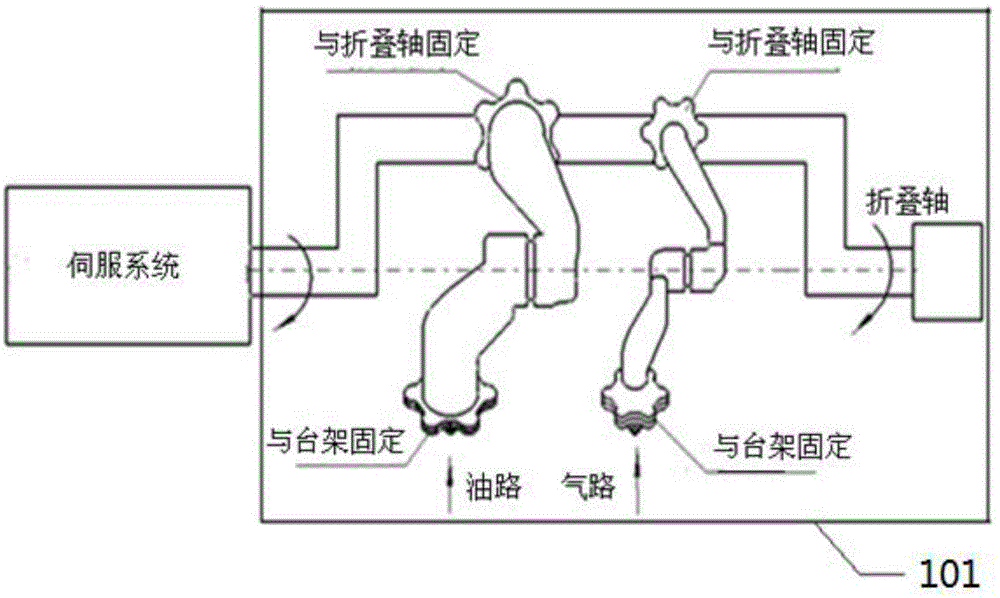

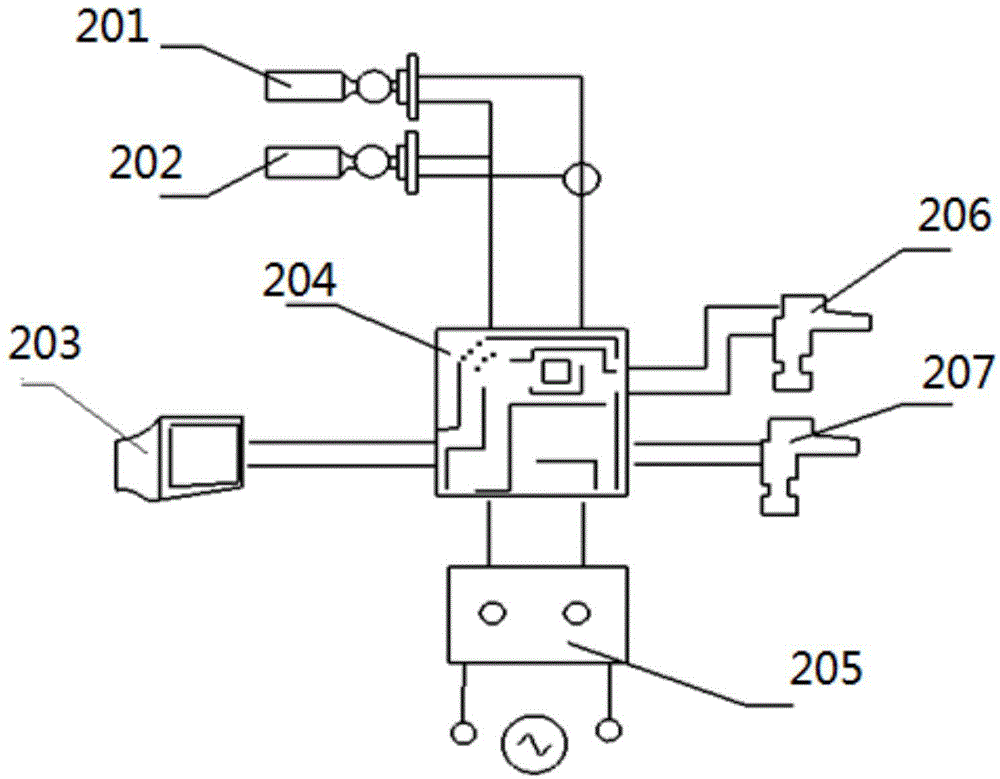

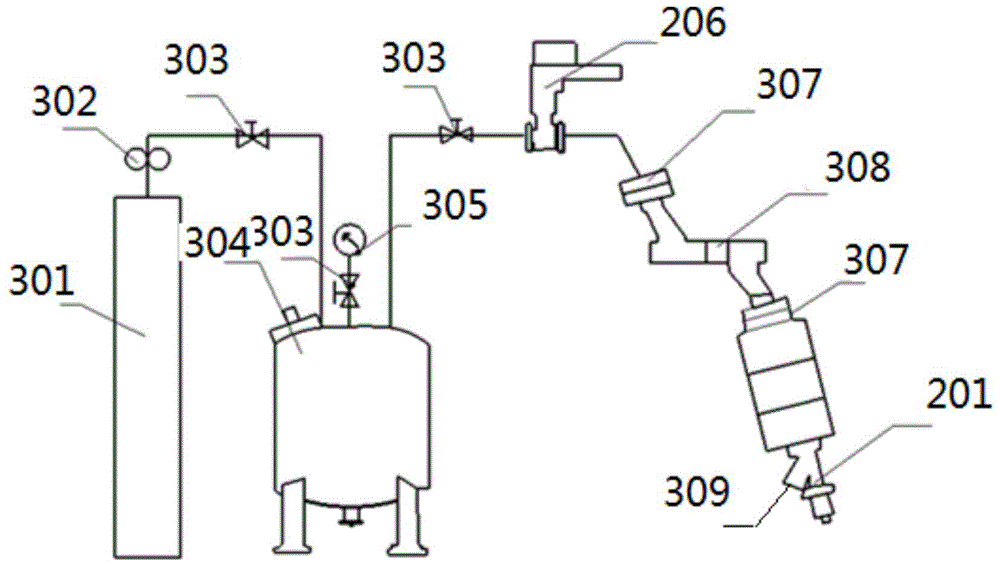

[0023] Step 1. According to the operating conditions of the folding and rotating mechanism of the oil-gas circuit, set up the principle life verification test environment of the folding and rotating mechanism, see figure 1 : The life verification test environment includes the power and control part, the mechanical transmission and the fixed installation part of the oil and gas circuit; where:

[0024] The power and control part includes PLC control board 204, embedded computer, servo system, oil and gas circuit measurement and supply system, limit switch, control valve and power supply, used to realize the measurement and control of the load of the oil and gas circuit folding mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com