Coaxiality-adjustable winding type tensile fixture

A winding and concentricity technology, applied in the field of tensile fixtures, can solve the problems of easily damaged samples, load sensor damage, test failure, etc., to ensure test force and deformation measurement, facilitate clamping of samples, reduce sideways swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

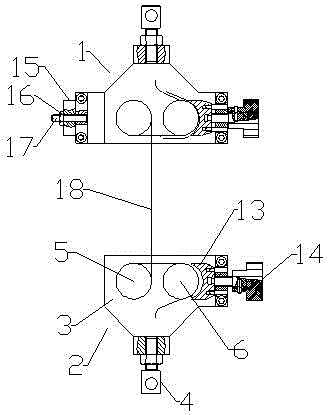

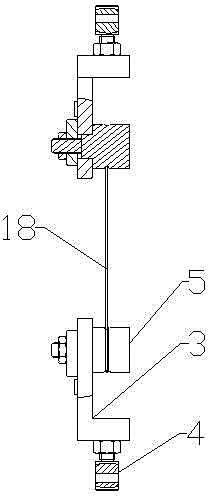

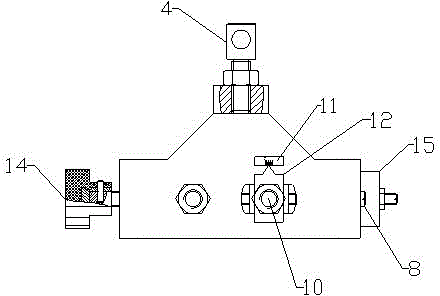

[0033] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 6 As shown, this kind of adjustable coaxiality winding tensile fixture includes an upper fixture 1 and a lower fixture 2 arranged in mirror image symmetry, and both the upper fixture 1 and the lower fixture 2 include an L-shaped clamp body 3, and the bending part The connection joint 4 is used to connect with the testing machine. The straight part of the clamp body 3 is equipped with winding columns 5 and pinch rollers 6 arranged horizontally. The pinch roller 6 is on the right. It can be welded on the clamp body 3 or The connection is fastened by fasteners, and the winding column 5 is on the left, such as image 3 , Figure 4 As shown, there is a hole on the clamp body 3 at this place, and there is a cuboid guide post 7 in the hole. The winding post 5 and the guide post 7 are integrally made, and the guide post 7 is threadedly connected to the guide screw 8. Below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com