Control method and device of blast furnace probe

A control method and control device technology, which is applied in the direction of using feedback control and inspection devices, can solve the problems of increased air flow, weakening the upward force of the iron lump, and the inability of the probe to detect the depth of the material surface accurately, so as to achieve accurate detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

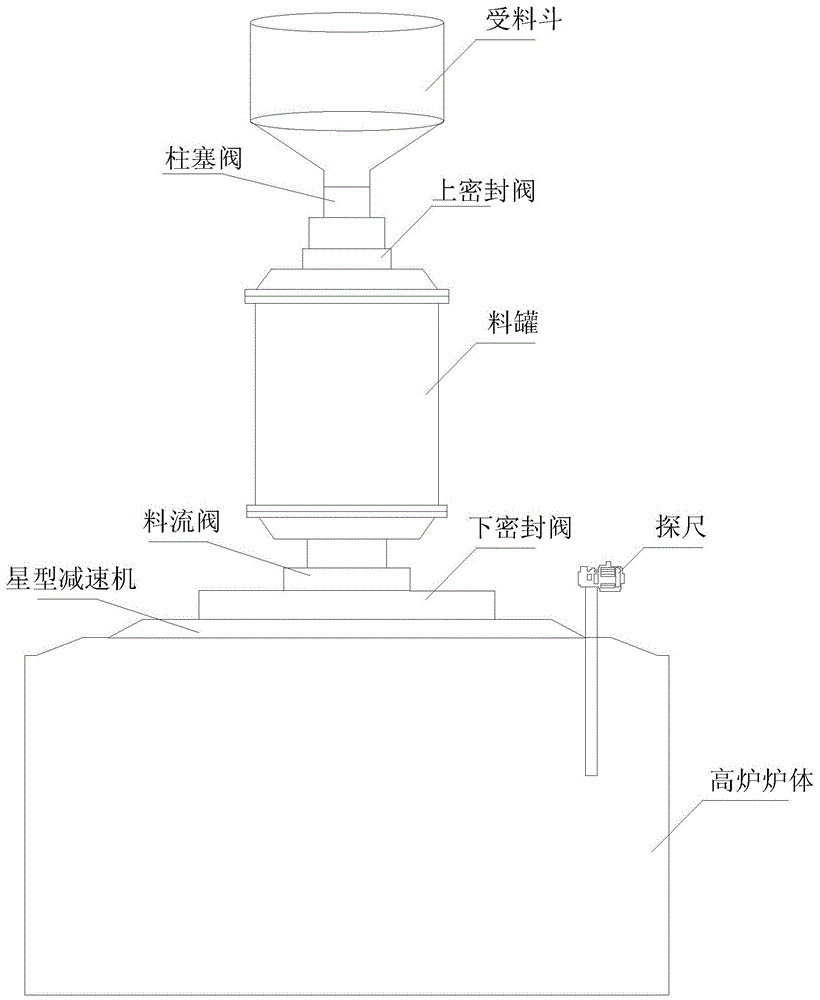

[0038] Embodiments of the present invention provide a method and device for controlling a blast furnace probe, so as to overcome the influence of irregular production of the blast furnace and enable the probe to accurately detect the depth of the material surface.

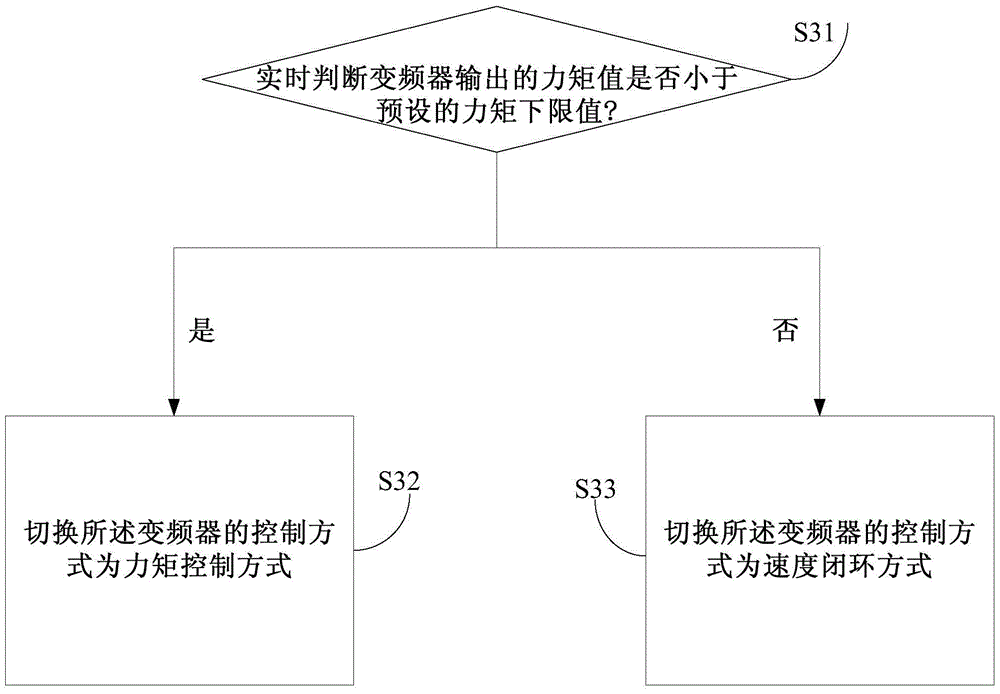

[0039] First, the control method of the blast furnace probe in the embodiment of the present invention is described, as image 3 As shown, at least the following steps are included:

[0040] Step S31: judge in real time whether the torque value output by the frequency converter is less than the preset torque lower limit value, if yes, go to step S32; if not, go to step S33.

[0041] In the embodiment of the present application, since the probe is in the process of putting the ruler, the speed closed-loop method is generally adopted, and the ruler is moved at a constant speed according to the speed set inside the frequency converter. Because in the speed closed-loop mode, the iron lump descends at a constant speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com