Structure design method for improving plug and socket plugging precision

A technology of plug and socket and structural design, applied in the direction of preventing wrong connection, fixed connection, circuit/collector parts, etc. dislocation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

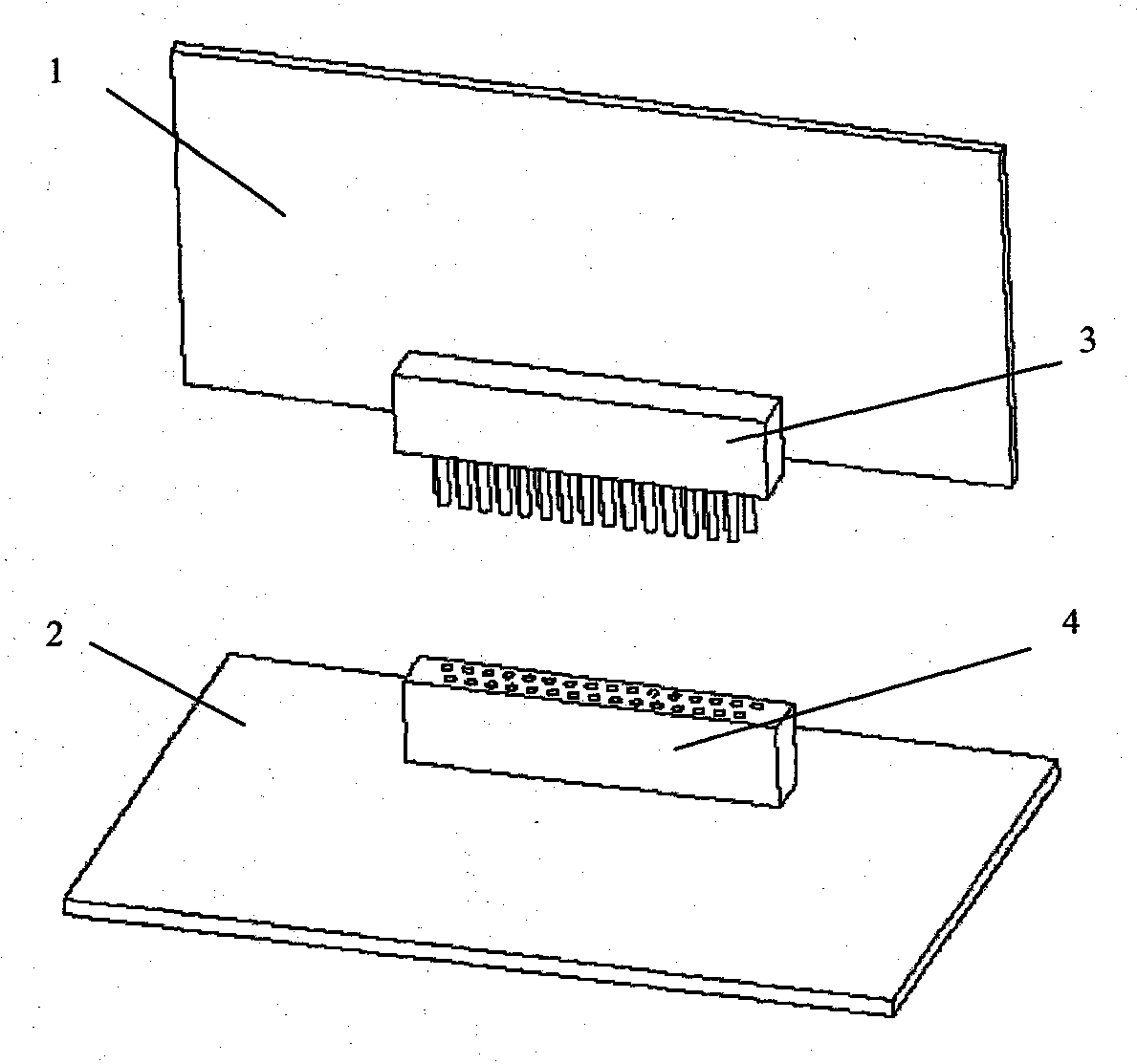

[0020] Electronic equipment often uses plugs and sockets to realize signal transmission between two printed boards. See figure 1 . The structural unit where the plug socket is located can be simplified as a sub-board combination and a motherboard combination.

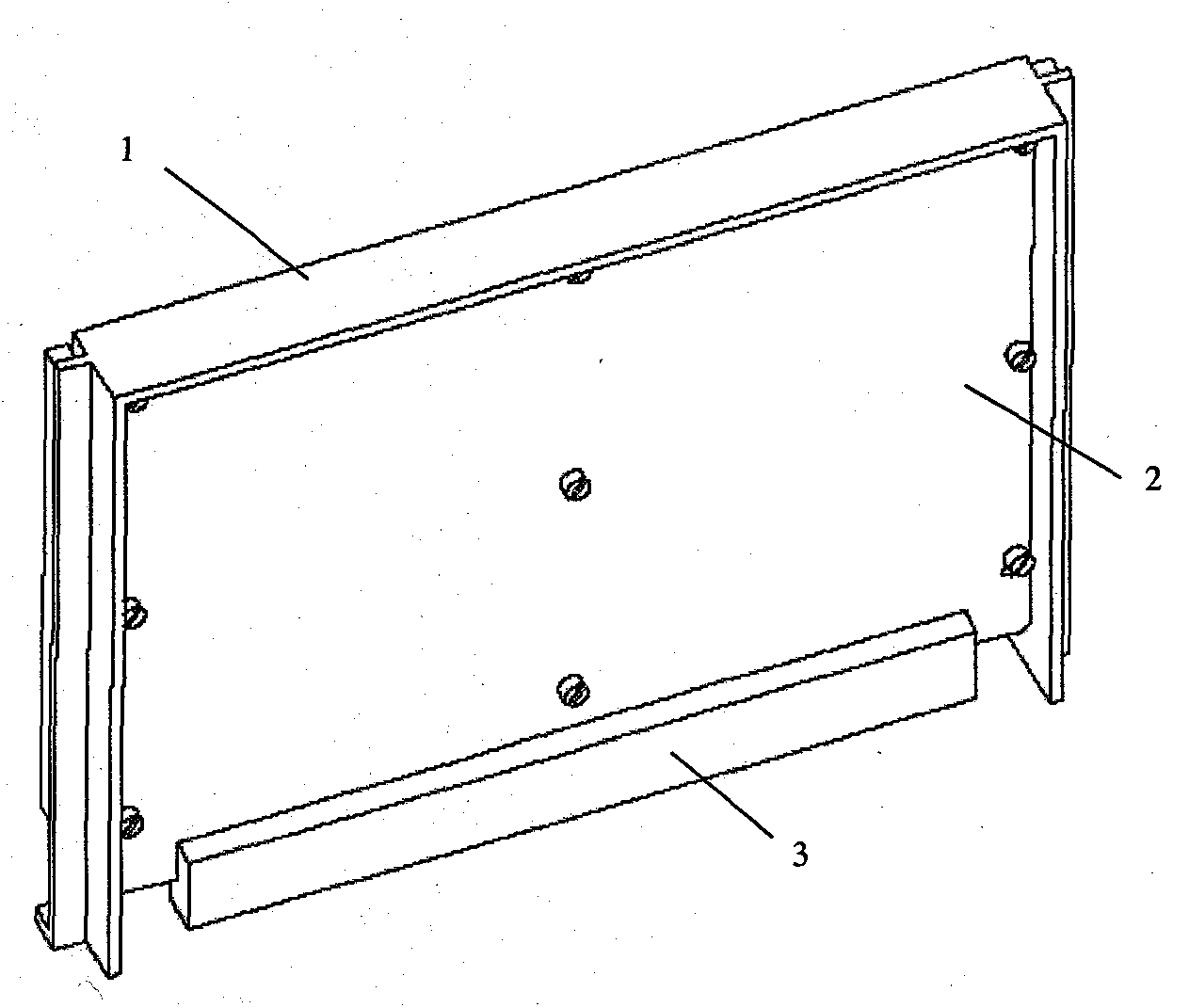

[0021] For sub-board composition see figure 2 , consists of a sub-board frame, a sub-board printed board, and a sub-board plug. The daughterboard plug is soldered to the daughterboard printed board, and then fixed together on the daughterboard frame.

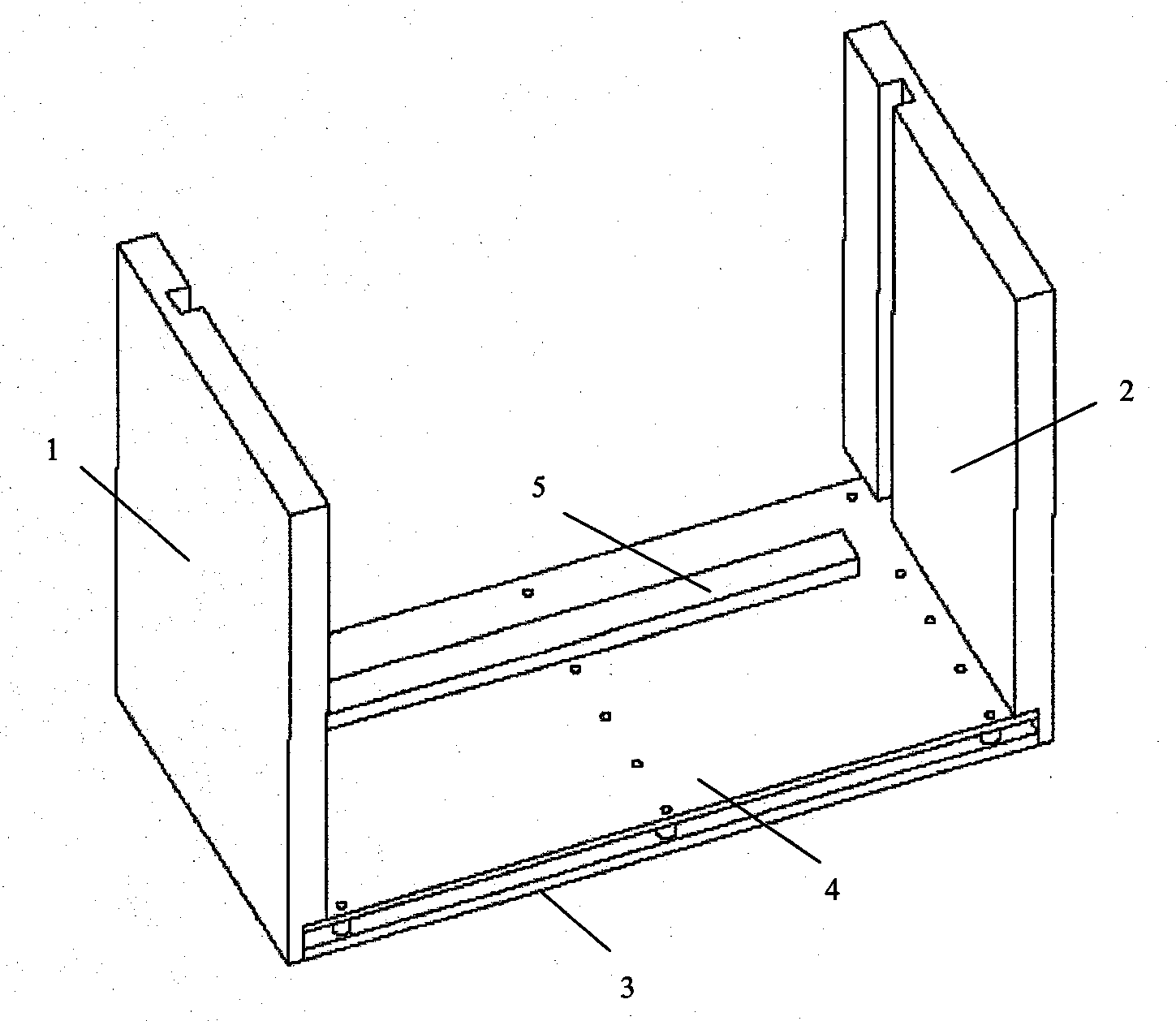

[0022] Motherboard composition see image 3 , consists of a left side board, a right side board, a bottom board, a motherboard printed board, and a motherboard socket. The left panel, the right panel and the bottom panel together form a structural frame. The motherboard socket is welded on the motherboard printed board, and then fixed together on the bottom plate.

[0023] Daughter board combination via Figure 4 Insert it from the grooves on the left side board a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com