Manual rice cutter

A cutter and paddy technology, applied in the direction of cutters, hand tools, agricultural machinery and implements, etc., can solve the problems of increased labor intensity, easy cutting, backward farming and harvesting methods, etc., to achieve simple and reasonable structure, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

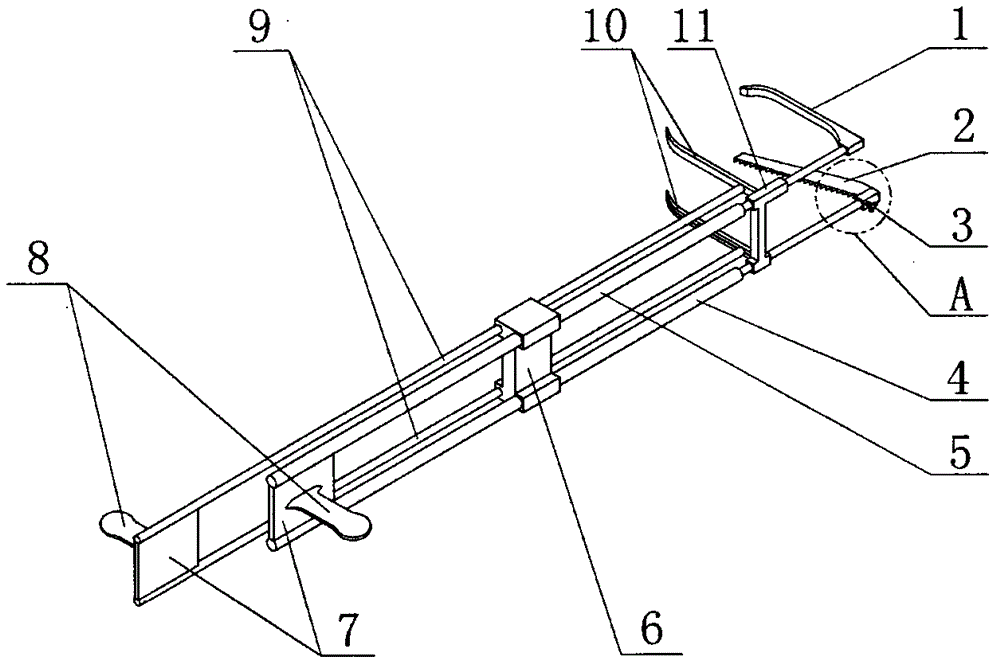

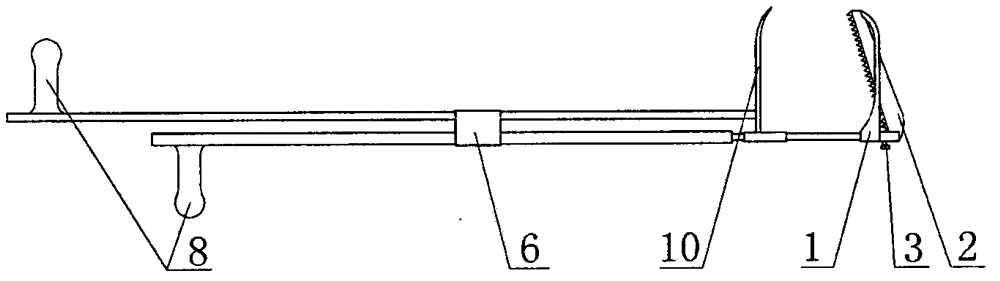

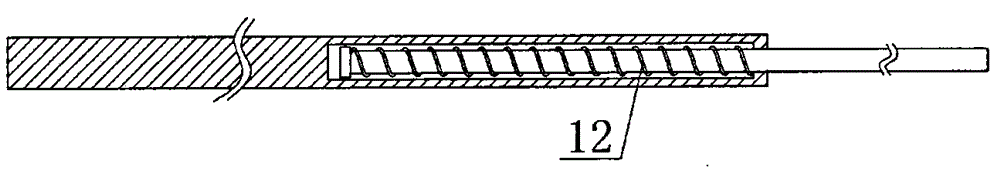

[0012] As shown in the drawings, a kind of artificial rice cutter of the present invention mainly consists of movable claw 1, cutter 2, lock nut 3, movable pull rod 4, telescopic rod 5, guide block 6, connecting plate 7, handle 8, The support rod 9, the fixed claw 10, the claw frame 11, and the spring 12 are composed of the movable claw 1 fixedly installed on the telescopic rod 5, and the telescopic rod 5 is connected with the movable pull rod 4 through the connecting plate 7, and the movable pull rod 4 is equipped with a cutting knife 2. The locking nut 3 is installed on the cutting knife 2, and the claw frame 11 forms a sliding connection with the telescopic rod 5 and the movable pull rod 4 respectively. Two fixed claws 10 are arranged on the claw frame 11, and the two support The rods 9 are fixedly connected with two fixed claws 10 respectively, and a guide block 6 and a connecting plate 7 are fixedly installed between the two support rods 9, and the guide block 6 forms a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com